Duplex Stainless Steel Flanges

Table of Content

- Duplex Stainless Steel Flanges Supplier

- Types of Grade S31803 / S32205 Duplex Steel Flanges

- ASME SA 276 Duplex SS Flanges Specifications

- Chemical Composition of ASTM 276 Duplex Stainless Steel Flanges

- Size Chart for ASTM A182 Duplex Steel Flanges

- Duplex SS Flanges Mechanical Properties

- Benefits of S31803 / S32205 Duplex Steel Flanges

- Duplex Steel Flanges Applications

- FAQs

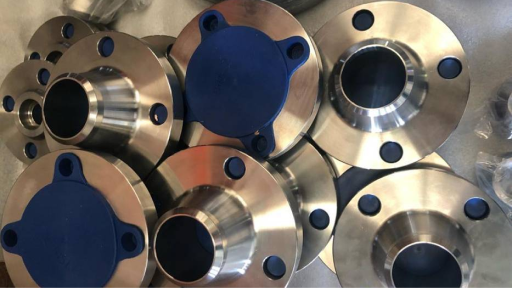

Best Price of 2205 Duplex WNRF Flanges Exporter, Ferritic / Austenitic Duplex Steel 2205 Industrial Flanges, Stockholder Of Duplex Steel S31803 RTJ Flange, ASME SA182M Duplex Steel S32205 Class 300 Flange Wholesaler, Duplex Flat Flange, Duplex EN 1092-1 Flanges.

Duplex Stainless Steel Flanges Supplier

Lakshya Steel is leading supplier of Duplex stainless steel flanges offer excellent resistance to weathering and have strong mechanical strength. Our Duplex stainless steel flanges are available in various sizes and dimensions to meet customer requirements. These flanges are ideal for use in extreme conditions and in highly volatile areas where welding can be dangerous. Duplex S31803 / S32205 Flanges at our in-house production center, specializing in flanges made from rare metals. We follow a rigorous quality control process, where every product is thoroughly tested and evaluated based on various parameters. Our Duplex Steel UNS S31803 Blind Flanges are precisely made to function as reliable, water-proof seals for pipe ends, offering excellent resistance to general corrosion. We also supply ASME SA182 Duplex Steel UNS S32205 Weld Neck Flanges, which are perfect for use in seawater environments and power generation equipment. These flanges feature smooth surfaces that can withstand temperatures up to 600°F while ensuring optimal flow characteristics.

Our Duplex Steel DIN 1.4410 Socket Weld Flanges are engineered to handle gases up to 600 psi and are carefully packaged and shipped to the nearest port for your convenience. The seamless coordination between our production and sales teams enables us to supply our products worldwide. We offer a wide range of Duplex Steel ASTM A182 Flanges, including Duplex 2205 Slip On Flanges, Duplex Steel S31803 Weld Neck Flanges, Duplex F51 Socket Weld Flanges, Gr. F52 Duplex Blind Flanges, Duplex Steel F56 Orifice Flanges, Duplex Steel S32205 Spectacle Blind Flanges, Duplex Steel F60 Screwed/Threaded Flanges, Duplex Steel F61 Reducing Flanges, and Duplex 2205 Ring Type Joint Flanges (RTJ), among others.

For more details on Duplex Stainless Steel Flanges, you can check out our blog on Duplex Blind Flanges.

These ASME SA182 Duplex Steel Flanges are available in various sizes, shapes, specifications, and thicknesses to meet our clients’ specific requirements. They are widely used in industries such as Chemical, Oil & Gas, Fertilizer, and Engineering. Duplex Stainless Steel S31803 & S32205 Welded Flanges are highly recommended for their excellent stress corrosion cracking (SCC) resistance, a property inherited from the ferritic side of stainless steel. Duplex Steel Flanges, containing elements like chromium, molybdenum, and nitrogen, provide strong resistance against chloride pitting and crevice corrosion. Additionally, due to their lower nickel and molybdenum content compared to austenitic stainless steels, Duplex stainless steels offer similar corrosion resistance at a more economical cost.

Explore our extensive selection of stainless steel products

Types of Grade S31803 / S32205 Duplex Steel Flanges

Factors to Consider When Choosing Duplex Steel Flanges

- Pressure Rating and Temperature: Ensure the flange meets your project’s pressure and temperature requirements.

- Size and Dimensions: Match the flange size to the pipe and check dimensions for a secure fit.

- Corrosion Resistance and Material: Choose the right Duplex steel alloy for your environment and application.

- Flange Face and Finish: Select the correct flange face (flat, raised, or ring joint) and surface finish (smooth, serrated, or grooved).

- End Connections and Joining: Pick the appropriate connection type (butt-weld, socket-weld, threaded, or flanged) based on your system’s needs.

Duplex Stainless Steel Flanges Specifications

| Standard | ASTM A182 / ASME SA182 |

| Dimensions | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Flange Size Chart | 1/2″ (15 NB) to 48″ (1200NB), DN10~DN5000 |

| Pressure Rating | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| JIS | 16 K, 5K, 10 K, 20 K, 30 K, 40 K, 63 K |

| Flange Connection / Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove, Flange Pipe. |

| Origin | West Europe / Japan / Indian / USA / Korean |

| Types of Flanges | Threaded / Screwed / Forged / Plate |

| Coating | Yellow Transparent, Zinc Plated, Anti-rust Paint, Oil Black Paint, Cold and Hot Dip Galvanized |

| Production technique Used | Heat treated, Forged and Machined |

| Equipment | Press machine, Bending machine, Pushing Machine, Sand-blasting machine, electric bevelling machine etc. |

| Test Certificates | EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report, etc |

Chemical Composition of Duplex Stainless Steel Flanges

The chemical composition of duplex steel flanges typically includes elements such as:

- Chromium (Cr): Provides corrosion resistance.

- Nickel (Ni): Contributes to strength and toughness.

- Molybdenum (Mo): Enhances corrosion resistance, especially in chloride environments.

- Nitrogen (N): Improves strength and corrosion resistance.

- Iron (Fe): The base element providing structural integrity.

The exact composition may vary depending on the grade and specific requirements of the application.

Size Chart for Duplex Steel Flanges

| Type | Dimension range * | Drawing** |

|---|---|---|

| Duplex Steel Blind Flanges Duplex Steel Blind Flanges |

DN15 – DN2500 ½ “- 24” |

DIN2527 PN16 DN150 BL 300lb 6 “ |

| Duplex Steel Threaded with neck Duplex Steel Threaded Flanges |

DN15 – DN150 ½ “- 24” |

DIN2566 DN32 / 42.4 TH 300lb 1 “ |

| Flanges smooth for welding | DN15 – DN2500 | DIN2576 DN150 |

| Duplex Steel Welding neck Duplex Steel Welding Neck Flanges |

DN15 – DN2500 ½ “- 24” Dy10 – Dy2400 |

DIN2635 DN150 / 168.3 WN 300lb 6 “GOST Dy150 Py16 |

| Duplex Steel loose flanges, smooth Bunde | DN15 – DN2500 | DIN2642 DN150 |

| Duplex Steel loose flanges Stub | DN15 – DN2500 | DIN2673 DN150 |

| Duplex Steel Welding flanges with neck Duplex Steel Slip On Flanges |

DN15 – DN2500 ½ “- 24” Dy10 – Dy2400 |

DIN86030 DN150 SO 300lb 6 ” GOST |

| Duplex Steel Lap Joint Flanges | ½ “- 24” | LJ 300lb 6 “ |

| Duplex Steel Socket Welding Flanges | ½ “- 3” | SW 300lb 6 “ |

410 Stainless Steel Fasteners Types

Duplex Stainless steel Flanges Mechanical Properties

The mechanical properties of duplex steel flanges depend on factors such as grade, manufacturing process, and heat treatment. However, typical mechanical properties include:

- Tensile Strength: Typically ranging from 620 to 900 MPa, depending on the grade and condition.

- Yield Strength: Varies between 450 and 700 MPa, influencing the material’s ability to withstand deformation under load.

- Elongation: Generally, ranges from 25% to 30%, indicating the material’s ductility.

- Hardness: Typically, in the range of 20 to 35 HRC (Rockwell hardness), depending on the grade and heat treatment.

Benefits of S31803 / S32205 Duplex Stainless Steel Flanges

- Corrosion Resistance: Superior resistance to corrosion compared to conventional stainless steel.

- High Strength: Greater tensile and yield strength for improved reliability and durability.

- Cost-Effectiveness: Long-lasting performance reduces maintenance costs, making them economical.

- Versatility: Can handle a wide range of temperatures and pressures, suitable for diverse applications.

- Stress Corrosion Cracking Resistance: Effective against stress corrosion cracking in harsh environments.

Duplex Steel Flanges Applications

– Petrochemical Industries

– Cement Industries

– Chemical Industries

– Oil & Gas Industries

– Power Plant Industries

– Shipbuilding Industries

– Fertilizer Industries

– Sugar Industries

– Engineering Projects

FAQs

What is a Duplex Stainless Steel Flange?

A duplex stainless steel flange is made from a type of stainless steel that combines both austenitic and ferritic structures. This unique composition gives it higher resistance to stress corrosion cracking compared to regular austenitic grades like 304 and 316 stainless steel. However, it has slightly lower toughness and impact strength. Common grades of duplex stainless steel flanges include 2205, F51, F53, and F60.For more information, please contact us.

When should I use duplex flanges?

What are the different types of duplex flanges?

Countries We Deliver

Taiwan, Mexico, Iran, Namibia, Afghanistan, Netherlands, Nepal, Ireland, Libya, Morocco, Iran, Switzerland, Finland, Slovakia, Pakistan, Australia, Serbia, Angola, China, Philippines, Czech Republic, Belgium, Estonia, Costa Rica, Croatia, Sweden, Venezuela, Colombia, India, Belarus, Jordan, Azerbaijan, Mongolia, Vietnam, Ghana, Iraq, Algeria, Puerto Rico, New Zealand, Singapore, Indonesia, Ukraine, Israel, Mexico, Hong Kong, Bhutan, Germany, Brazil, Plan, Yemen, Malasiya, USA, Cambodia, Laos, Uganda, Tanzania, Sudan, Democratic Republic of Congo, zambia, Ethiopia, Brunei, Madagascar, Niger, Mali, Bangladesh, Bolivia, United States, Ecuador, Lebanon, Italy, South Korea, Denmark, Norway, Sri Lanka, Zimbabwe, Japan, Yemen, Oman, Portugal, Lithuania, Canada, Macau, Bahrain, Austria, Bulgaria, Spain, Kenya, United Kingdom, United Arab Emirates, Kazakhstan, Egypt, Saudi Arabia, Gambia, Argentina, Romania, Tibet, France, Chile, Gabon, South Africa, Trinidad & Tobago,Tunisia, Turkey, Nigeria, Peru, Russia, Chile, Nigeria, Hungary, Qatar, Greece, Malaysia, Kuwait, Poland, Thailand, Poland.

Cities We Deliver

New York City, Los Angeles, Chicago, Houston, Phoenix, Philadelphia, San Antonio, San Diego, Dallas, San Jose, Austin, Jacksonville, Fort Worth, Columbus, Charlotte, San Francisco, Indianapolis, Seattle, Denver, Washington, Boston, El Paso, Nashville, Detroit, Oklahoma City, Portland, Las Vegas, Memphis, Louisville, Baltimore, Milwaukee, Albuquerque, Tucson, Fresno, Mesa, Sacramento, Atlanta, Kansas City, Colorado Springs, Omaha, Raleigh, Miami, Long Beach, Virginia Beach, Oakland, Minneapolis, Tulsa, Tampa, Arlington, New Orleans, Wichita, Bakersfield, Cleveland, Aurora, Anaheim, Honolulu, Santa Ana, Riverside, Corpus Christi, Lexington, Henderson, Stockton, Saint Paul, Cincinnati, St. Louis, Pittsburgh, Greensboro, Lincoln, Anchorage, Plano, Orlando, Irvine, Newark, Durham, Chula Vista, Toledo, Fort Wayne, St. Petersburg, Laredo, Jersey City, Chandler, Madison, Lubbock, Scottsdale, Reno, Buffalo, Gilbert, Glendale, North Las Vegas, Winston-Salem, Chesapeake, Norfolk, Fremont, Garland, Irving, Hialeah, Richmond, Boise, Spokane, Baton Rouge, Tacoma, San Bernardino, Modesto, Fontana, Des Moines, Moreno Valley, Santa Clarita, Fayetteville, Birmingham, Oxnard, Rochester, Port St. Lucie, Grand Rapids, Huntsville, Salt Lake City, Frisco, Yonkers, Amarillo, Glendale, Huntington Beach, McKinney, Montgomery, Augusta, Aurora, Akron, Little Rock, Tempe, Columbus, Overland Park, Grand Prairie, Tallahassee, Cape Coral, Mobile, Knoxville, Shreveport, Worcester, Ontario, Vancouver, Sioux Falls, Chattanooga, Brownsville, Fort Lauderdale, Providence, Newport News, Rancho Cucamonga, Santa Rosa, Peoria, Oceanside, Elk Grove, Salem, Pembroke Pines, Eugene, Garden Grove, Cary.

Our Products

Our Latest Blogs

316 Stainless Steel Price List

Check 316 Stainless Steel Price list and SS 316 Price Per kg in India 316 stainless steel is a type of austenitic stainless steel that is known for its excellent corrosion resistance, particularly in chloride environments. It is the second most widely used grade of...

Related Products

- Stainless Steel 304 Single Slotted Pipe

- Stainless Steel 304 Double Slotted Pipe

- Stainless steel 304 fittings

- Stainless Steel 304 Components

- Stainless Steel 309 Rod/Bar

- Stainless Steel 309 Hex Bar

- Stainless Steel 309 Square Bar

- Stainless Steel 309 Welded Pipes

- Stainless Steel 309 Plates Sheet

- Stainless steel 309 fittings

- Stainless Steel 309 Components

- Stainless Steel 310 Rod / Bar

- Stainless steel 310 Hex Bars

- Stainless Steel 310 Square Bar

- Stainless Steel 310 Welded Pipes

- Stainless Steel 310 Plates/Sheet

- Stainless Steel 310 Seamless Pipes

- Stainless steel 310 Welded Tubes

- Stainless steel 310 fittings

- Stainless steel 310 channels

- Stainless steel 310 H Beam

- Stainless steel 310 I Beam

- Stainless steel 310 seamless tubes

- Stainless Steel 310 Components

- Stainless Steel 316 / 316Ti Flanges

- Stainless Steel 316 / 316Ti Rod

- Stainless Steel 316 / 316Ti Hex Bars

- Stainless Steel 316 / 316Ti Square Bars

- Stainless Steel 316 / 316Ti Seamless Pipes

- Stainless Steel 316 / 316Ti Welded Pipes

- Stainless Steel 316 / 316Ti Plates

- Stainless Steel 316 / 316Ti Welded Tubes

- Stainless Steel 316 / 316Ti Seamless Tubes

- Stainless Steel 316 / 316Ti Flat Bars

- Stainless Steel 316 / 316Ti Angles

- Stainless Steel 316 / 316Ti Channels

- Stainless Steel 316 / 316Ti H Beams

- Stainless Steel 316 / 316Ti I Beam

- Stainless Steel 316 / 316Ti Pipe Fittings

- Stainless Steel 316 Single Slotted Pipe

- Stainless Steel 316 Double Slotted Pipe

- Stainless Steel 316/316Ti Components

- Stainless Steel 317L Flanges

- Stainless Steel 317L Rod/Bar

- Stainless Steel 317L Hex Bar

- Stainless steel 317L Square Bar

- Stainless Steel 317L Plates/Sheet

- Stainless steel 317L channels

- Stainless steel 317L H Beam

- Stainless steel 317L I Beam

- Stainless steel 317L fittings

- Stainless Steel 317L Components

- Stainless Steel 321 / 347 Flanges

- Stainless Steel 321/347 Rod/Bar

- Stainless Steel 321/347 Hex Bar

- Stainless Steel 321/347 Square Bar

- Stainless Steel 321/347 Seamless Pipes

- Stainless Steel 321/347 Welded Pipes

- Stainless Steel 321 / 347 Pipe Fittings

- Stainless Steel 321/347 Plates/Sheet

- Stainless steel 321 / 347 Welded Tubes

- Stainless steel 321 / 347 seamless tubes

- Stainless steel 321 / 347 channels

- Stainless steel 321 / 347 H Beam

- Stainless steel 321 / 347 I Beam

- Stainless Steel 321 / 347 Components

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 Flange

- Stainless Steel 409/409M/409L/410/430/430F/431/439/441 Rod/Bars

- Stainless Steel 409/409M/409L/410/430/430F/431/439/441 Hex Bar

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 Square Bar

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 Welded Pipes

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 Sheet /Plates/Coil

- Stainless Steel 409/409M/409L/410/430/430F/431/439/441 Welded tubes

- Stainless Steel 409/409M/409L/410/430/430F/431/439/441 Channel

- Stainless Steel 409/409M/409L/410/430/430F/431/439/441 H Beam

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 I Beam

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 Components

- Stainless Steel 420/ 420B & 420C Rod/Bar

- Stainless steel 420 / 420B & 420C hex bars

Send Us Message

Got a question? We'd love to hear from you. Send us a message & we'll respond as soon as possible.