Blind flanges are vital components in piping systems, serving to close the end of a pipe and prevent leaks. They play a crucial role in protecting the piping system from damage. Understanding the various blind flanges types is most important for selecting the right one for your project. In this blog post, we’ll delve into the different types of blind flanges and their specific applications, helping you make an informed choice for your piping needs.

Read More: Types of Stainless Steel Flanges

What is a Blind Flange?

Blind flanges are providing a means to seal off the end of a pipe or vessel. These flanges are typically solid discs bolted onto the pipe’s end, typically with a defined facing for sealing. Blind Flanges are used for many applications, including:

- Isolation of pipe sections for maintenance or repair

- Termination of pipelines

- Pressure testing

- Access points for cleaning or inspection

Blind flanges come in various diameters, materials, and pressure ratings. Installation is straightforward: they are bolted onto the pipe’s open end with a gasket for a tight, leak-free seal. Evenly tightening the bolts ensures a secure connection.

Common Stainless Steel Grades Used for Blind Flanges

Blind flanges are crafted from a range of stainless steel grades to suit different needs. SS304 flanges offer excellent corrosion resistance and weldability, while SS316 excels in chloride-rich environments. SS316L provides enhanced corrosion resistance for welded parts, and SS317 flanges are highly resistant to acids and high temperatures. SS321 flanges are ideal for elevated temperatures with excellent intergranular corrosion resistance, and SS904L is exceptionally resistant for harsh conditions like sulfuric acid environments. The choice of grade depends on the specific operating conditions and mechanical demands of the application.

Types of Blind Flanges

1. Raised Face Blind Flanges

Raised face blind flanges feature a raised ring around the face of the flange, creating a seal when mated with a similarly raised face flange. This design is suitable for high-pressure applications due to its increased sealing surface area.

2. Ring Joint Blind Flanges

Ring joint blind flanges utilize a metal ring gasket to seal the connection. This type of flange is particularly effective in high-pressure and high-temperature applications, as the ring gasket can withstand extreme conditions.

3. Flat Face Blind Flanges

Flat face blind flanges have a flat face without any raised areas. This design is less common than raised face or ring joint flanges due to its lower sealability. However, flat face flanges are still suitable for low-pressure applications.

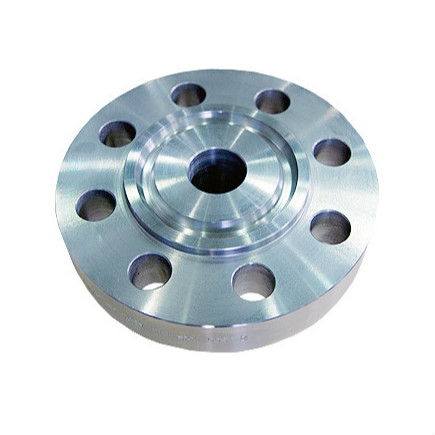

4. Weld Neck Blind Flanges

Weld neck blind flanges are attached to the pipe by a circular weld around the neck of the flange. This design provides excellent strength and is suitable for high-pressure and high-temperature applications.

5. Close Nipple Blind Flanges

Close nipple blind flanges are similar to weld neck flanges, but they have a shorter neck. This design is typically used in tight spaces where a full-length neck would interfere with other components.

Conclusion

In conclusion, the selection of the appropriate blind flange type holds considerable sway over the success of your piping project. It providing a reliable means to seal off pipe sections and access points. The specific type of blind flange selected depends on the application’s pressure rating, temperature requirements, and space constraints. By understanding the characteristics and uses of different blind flanges, engineers and technicians can make informed decisions to ensure the safe and efficient operation of piping systems.

FAQS:

What are the benefits of blind flanges?

Blind flanges offer leak prevention and system isolation, making them ideal for maintenance. They are versatile, available in various sizes and materials, easy to install with bolted connections, and durable for long-term use.

When should I use a blind flange?

Use a blind flange to close the end of a pipe, isolate a section for maintenance or repairs, prevent leaks, or block fluid or gas flow in a pipeline.

Does a blind flange require a gasket?

Yes, a blind flange typically requires a gasket to ensure a tight, leak-free seal.

Will blind flanges work as spacers?

No, blind flanges are not designed to work as spacers.

How to install a blind flanges in a piping system?

To install a blind flange, ensure a clean pipe end, align and bolt the flange, add a gasket for a tight seal, and tighten bolts evenly in a crisscross pattern until secure. Inspect for leaks before operation.

What is a blind flange used for?

A blind flange is used to close the end of a pipe or vessel temporarily, preventing the flow of fluids or gases in a piping system.