321 Stainless Steel

321 stainless is a grade that is stabilized with titanium and is often used for work between 1000 and 1600°F. A stabilizing treatment at 1550–1650°F and air cooling can be used for service temperatures up to around 1600°F to give excellent resistance to intergranular corrosion and polythionic acid stress corrosion cracking.

All common ways to weld, like submerged arc, work well with 321 stainless. AWS ER347 bare wire and E347 covered electrodes are good weld fillers. 321 stainless steel is easy to work with, just like 304 stainless steel. Compared to AISI B112, it can be worked on by machines 45 percent of the time.

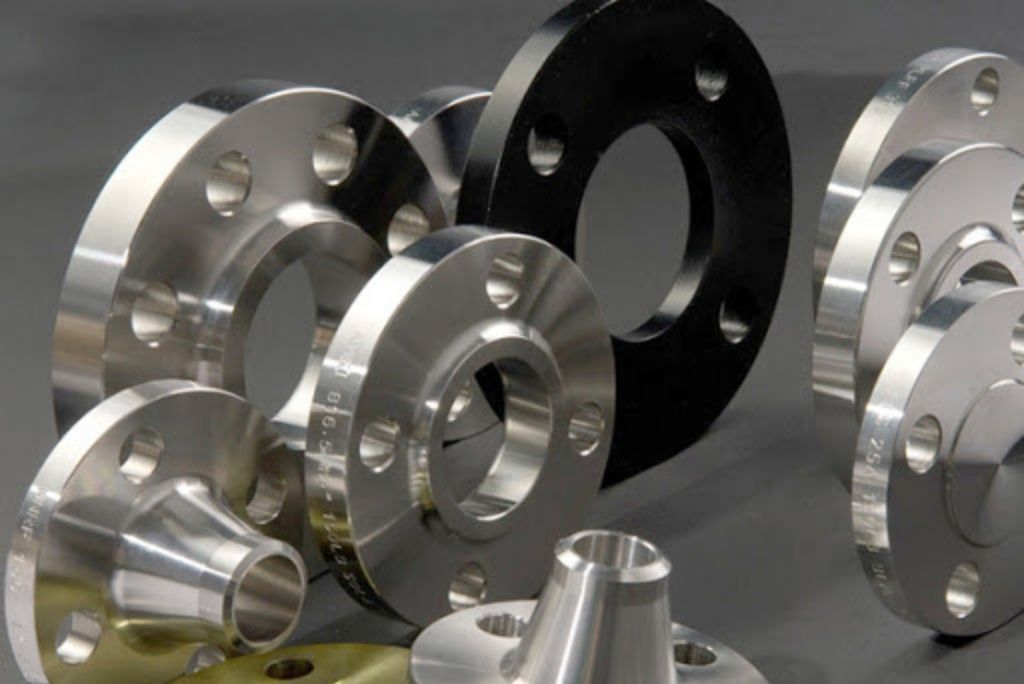

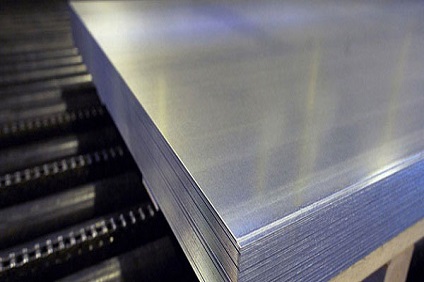

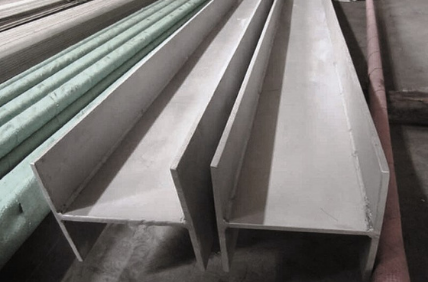

Inventory

321 Flanges, 321 Rod Bar, 321 Hex Bar, 321 Square Bar, 321 Seamless Pipes, 321 Welded Pipes, 321 Pipe Fittings, 321 Plates / Sheets, 321 Welded Tubes, 321 Seamless Tubes, 321 Channels, 321 H Beam, 321 I Beam, 321 Components.Common Trade Names

321, 321 Stainless, Alloy 321Features

oxidation-resistant up to 1600°F stabilized against weld heat-affected zone (HAZ) intergranular corrosion Avoids polythionic acid stress corrosion crackingApplications

Manifolds for airplane piston engines Expansion joints The making of guns Heat-based oxidizers Refinery equipment Chemical equipment that can handle high temperatures347 Stainless Steel

In environments with a lot of oxygen, type 347 stainless steel has slightly better corrosion resistance than type 321 stainless steel. Type 347 is stabilized with columbium. Because of its good resistance to intergranular attack, it is better for environments with water and low temperatures. Both 347 and 321 are resistant to polythionic acid stress corrosion cracking, which happens in oil refineries. The ability of 347 to not rust at high temperatures is similar to that of 304 stainless steel. works up to 1500°F.

The grain size and carbon content of many products can meet both the 347S and 347H requirements. AWS ER347 bare wire and E347 covered electrodes are good weld fillers.