Stainless Steel 316 Tube

Stainless Steel 316 Tube

Table of Content

- 316 Stainless Steel Tube Supplier

- Stainless Steel 316 Tube Specifications

- 316 Stainless Tube Chemical Composition

- 316 Stainless Tube Mechanical Properties

- 316 SS Tubing Physical Properties

- 316 Stainless Steel Tube Equivalent Grades

- 316 Stainless Steel Tube Sizes

- 316 SS Tubing Wall Thickness

- 316 Stainless Tube Industrial Applications

- Stainless Steel 316 Density

- FAQ’s

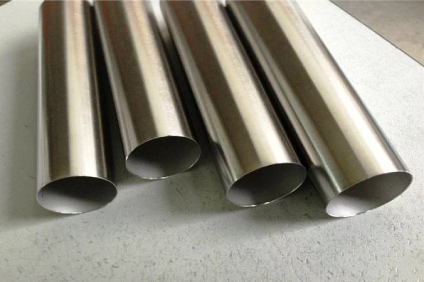

Stainless steel 316 tubes are high-quality pipes made from an austenitic grade of stainless steel, known for their outstanding corrosion resistance, especially against chloride ions. This makes them particularly well-suited for marine and seawater environments, where other materials may not hold up.

316 stainless steel tubes are built to withstand tough conditions, offering reliable, long-lasting performance. Their strength and security come from their high content of chromium, nickel, and molybdenum.

These tubes are available in various sizes to meet different needs, from industrial uses to everyday applications. Whether you need them for construction, chemical processing, or food production, 316 stainless steel tubes provide a versatile and robust solution. They also offer excellent corrosion resistance and are easy to weld, making them ideal for a wide range of demanding applications.

316 Stainless Steel Tube Supplier

SS 316 Tube, Stainless Steel 316 Tube, Stainless Steel 316 Tubing, 316 Seamless Stainless Steel Tube, Stainless Steel 316 Tubes Manufacturer, 316 SS Tubing, 316 Stainless Tube Suppliers

Lakshya Steel is a leading supplier, manufacturer, stockist, and exporter of stainless steel products including 316 stainless steel tubes. Our 316 stainless steel tubes are made from high-quality materials, meeting both national and international standards for strength and quality. We offer 316 stainless steel tubes with low carbon content (max 0.03%) that enhance corrosion resistance, making them ideal for use in structural applications like handrails, machine supports, and environments with high temperatures. These tubes come in different shapes, sizes, and finishes, perfect for architectural projects, marine environments, and industrial processes.

Our 316 stainless steel products are known for their strength, security, and excellent corrosion resistance. Whether you need seamless tubes, which are stronger, or welded tubes, which are more cost-effective, we ensure you get the best quality at competitive prices. The 316 grade is an austenitic stainless steel that includes chromium, nickel, and molybdenum, giving it strong corrosion resistance, especially in marine settings. Our 316 stainless steel tubing is highly resistant to pitting and crevice corrosion, making it a secure choice for tough environments. We also provide seamless tubing, which is made through an extrusion process, giving it higher strength, and welded tubing, which is more affordable and available in various sizes. Our SS grade 1.4401 Tube is known for its strong mechanical properties, including high tensile strength and flexibility. The WNR. 1.4401 Seamless Tube is dense and conducts heat well, making it suitable for a range of applications.

At Lakshya Steel, we pride ourselves on delivering top-quality products quickly and efficiently. If you have any questions or need more information about our 316 stainless steel tubes or other products, please visit our stores or contact us directly. We’re here to help!

Stainless Steel 316 Tube Specification

| Marking | All 316 Stainless Steel tubes are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

|---|---|

| Stainless Steel 316 Tube Standards | ASME SA269,ASTM A213,ASME SA249,ASTM A269, ASME SA213 , ASTM A249, NACE MR0175/ISO 15156, EN 10216-5 TC1 / TC2, PED 97/23/EC, AD 2000 |

| Stainless Steel 316 Seamless Tube Size | 3.35 mm OD To 101.6 mm OD |

| Value Added Service | Draw & Expansion as per required Size & Length, Polish (Electro & Commercial) Annealed & Pickled Bending, Machining Etc. |

| Stainless Steel 316 tubing wall thickness | 0.020″ –0.220″, (special wall thicknesses available) |

| Stainless Steel 316 Tube Type | Seamless, ERW, EFW, Welded, Fabricated |

| SS 316 tube Length | Single Random, Double Random, Standard & Cut length |

| 316 Stainless Steel Tube Finish | Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF |

| 316 stainless steel tubingApplication | Oil Tube, Gas Tube, Fluid Tube, Boiler and Heatexchanger |

| I.D. Surface Finish Options | 5, 7 & 10 µin. Ra |

| Non-Electropolished | (BA) Bright Annealed or (AP) Annealed & Pickled for High-Purity, (CFOS) Cleaned for Oxygen Grade Service or Corrosive Systems |

| Stainless Steel 316 tube Form | Round, Coil, Square, Rectangular, Boiler, Hydraulic, Straight or ‘U’ bent Tubes, Hollow, LSAW Tubes Etc. |

| JIS | 8A to 250A |

| Tolerances | In accordance with: ASTM: A269 & A632, JIS: G 3459 |

| Specialize in | Stainless Steel 316 Capillary Tube & Other Odd Size Stainless Steel 316 Heat Exchanger & Condenser Tubes Stainless Steel 316 Hydraulic tubing with OD up to 50.8 mm (2.0 in.) are delivered in bright annealed condition Stainless Steel 316 hydraulic tube with OD larger than 50.8 mm are supplied in the annealed and pickled condition, Or in polished condition |

| Electropolished | (EP) Electropolished for Ultra High Purity Systems |

| Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| Stainless Steel 316 Welded Tube Size | 6.35 mm OD To 152 mm OD |

| 316 stainless steel tubing End | Plain End, Beveled End, Treaded, Ends are suitable for orbital welding |

| Marking & Traceability | Each Stainless Steel 316 Tubing is traceable to its producing mill and heat by an identification number etched within 24″ (610mm) of one end. |

| 316 stainless steel tubing Test Certificate | Manufacturer Test Certificate according to EN 10204 3.1 B Laboratory Test Certificate from Govt. Approved Lab. Under Third Party Inspection |

| 316 stainless steel tubing Testing & Inspection | Visual inspection • Surface roughness measurement • Helium-leak testing • Scanning Electron Microscopy (SEM) • Auger Electron Microscopy (AES) • Election Spectroscopy for Chemical Analysis (ESCA or XPS) • Particle testing • Moisture testing |

| We can also cut, thread, and groove Stainless Steel 316 Tubes to meet your specifications | |

316 Stainless Tube Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 316 | min. | – | – | – | – | 16.0 | 2.0-3.0 | 10.0 | – | |

| max. | 0.035 | 2.0 | 0.75 | 0.045 | 0.030 | 18.0 | 14.0 | – | ||

316 Stainless Tube Mechanical Properties

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 316 | 515 | 205 | 40 | 95 | 217 |

316 SS Tubing Physical Properties

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (m/m/0C) | Thermal Conductivity (W/m.K) | Specific Heat 0-1000C (J/kg.K) | Electrical Resistivity (n.m) | |||

| 0-100°C | 0-315°C | 0-538°C | at 100°C | at 500°C | |||||

| 316 | 8000 | 193 | 15.9 | 16.2 | 17.5 | 16.3 | 21.5 | 500 | 740 |

316 Stainless Steel Tube Equivalent Grades

| STANDARD | UNS | WERKSTOFF NR. | JIS | AFNOR | BS | GOST | EN |

| SS 316 | S31600 | 1.4401 / 1.4436 | SUS 316 | Z7CND17‐11‐02 | 316S31 / 316S33 | – | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

Stainless Steel 316 Tube Types

316 Stainless Steel Tube Sizes

| Wall Thickness | Stainless Steel 316 Tube Sizes ( O.D.) |

| .010 | 1/16″ , 1/8″ , 3/16″ |

| .020 | 1/16″ , 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ |

| .012 | 1/8″ |

| .016 | 1/8″ , 3/16″ |

| .028 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 3/4″ , 1″ , 1 1/2″ , 2″ |

| .035 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 7/16″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .049 | 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/8″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .065 | 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 3/4″ , 2″ , 2 1/2″ , 3″ |

| .083 | 1/4″ , 3/8″ , 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 7/8″ , 2″ , 2 1/2″ ,3″ |

| .095 | 1/2″ , 5/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .109 | 1/2″ , 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .120 | 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 2 1/4″ , 2 1/2″ , 3″ |

| .125 | 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 3″ , 3 1/4″ |

| .134 | 1″ |

| .250 | 3″ |

| .375 | 3 1/2″ |

Stainless Steel 316 Tube Pressure Rating

| OD inches | Ave. Wall inches | Min Yield Strength (PSI) | Min Tensile Strength (PSI) | Theoretical Burst Pressure * (PSI) | Working Pressure (PSI) 25% of Burst | Theoretical Yield Point ** (PSI) | Collapse Pressure *** (PSI) |

| 0.250 | 0.020 | 30,000 | 75,000 | 14,286 | 3,571 | 5,714 | 4,416 |

| 0.250 | 0.028 | 30,000 | 75,000 | 21,649 | 5,412 | 8,660 | 5,967 |

| 0.250 | 0.035 | 30,000 | 75,000 | 29,167 | 7,292 | 11,667 | 7,224 |

| 0.250 | 0.049 | 30,000 | 75,000 | 48,355 | 12,089 | 19,342 | 9,455 |

| 0.250 | 0.065 | 30,000 | 75,000 | 81,250 | 20,313 | 32,500 | 11,544 |

| 0.375 | 0.020 | 30,000 | 75,000 | 8,955 | 2,239 | 3,582 | 3,029 |

| 0.375 | 0.028 | 30,000 | 75,000 | 13,166 | 3,292 | 5,266 | 4,145 |

| 0.375 | 0.035 | 30,000 | 75,000 | 17,213 | 4,303 | 6,885 | 5,077 |

| 0.375 | 0.049 | 30,000 | 75,000 | 26,534 | 6,634 | 10,614 | 6,816 |

| 0.375 | 0.065 | 30,000 | 75,000 | 39,796 | 9,949 | 15,918 | 8,597 |

| 0.500 | 0.020 | 30,000 | 75,000 | 6,522 | 1,630 | 2,609 | 2,316L |

| 0.500 | 0.028 | 30,000 | 75,000 | 9,459 | 2,365 | 3,784 | 3,172 |

| 0.500 | 0.035 | 30,000 | 75,000 | 12,209 | 3,052 | 4,884 | 3,906 |

| 0.500 | 0.049 | 30,000 | 75,000 | 18,284 | 4,571 | 7,313 | 5,316L |

| 0.500 | 0.065 | 30,000 | 75,000 | 26,351 | 6,588 | 10,541 | 6,786 |

| 0.500 | 0.083 | 30,000 | 75,000 | 37,275 | 9,319 | 14,910 | 8,307 |

| 0.625 | 0.020 | 30,000 | 75,000 | 5,128 | 1,282 | 2,051 | 1,859 |

| 0.625 | 0.028 | 30,000 | 75,000 | 7,381 | 1,845 | 2,953 | 2,568 |

| 0.625 | 0.035 | 30,000 | 75,000 | 9,459 | 2,365 | 3,784 | 3,172 |

| 0.625 | 0.049 | 30,000 | 75,000 | 13,947 | 3,487 | 5,579 | 4,335 |

| 0.625 | 0.065 | 30,000 | 75,000 | 19,697 | 4,924 | 7,879 | 5,591 |

| 0.625 | 0.083 | 30,000 | 75,000 | 27,124 | 6,781 | 10,850 | 6,910 |

| 0.625 | 0.095 | 30,000 | 75,000 | 32,759 | 8,190 | 13,103 | 7,734 |

| 0.625 | 0.109 | 30,000 | 75,000 | 40,172 | 10,043 | 16,069 | 8,639 |

| 0.750 | 0.028 | 30,000 | 75,000 | 6,052 | 1,513 | 2,421 | 2,156 |

| 0.750 | 0.035 | 30,000 | 75,000 | 7,721 | 1,930 | 3,088 | 2,669 |

| 0.750 | 0.049 | 30,000 | 75,000 | 11,273 | 2,818 | 4,509 | 3,664 |

| 0.750 | 0.065 | 30,000 | 75,000 | 15,726 | 3,931 | 6,290 | 4,749 |

| 0.750 | 0.083 | 30,000 | 75,000 | 21,318 | 5,330 | 8,527 | 5,905 |

| 0.750 | 0.095 | 30,000 | 75,000 | 25,446 | 6,362 | 10,179 | 6,637 |

| 0.750 | 0.109 | 30,000 | 75,000 | 30,733 | 7,683 | 12,293 | 7,453 |

| 0.750 | 0.120 | 30,000 | 75,000 | 35,294 | 8,824 | 14,118 | 8,064 |

| 0.875 | 0.020 | 30,000 | 75,000 | 3,593 | 898 | 1,437 | 1,340 |

| 0.875 | 0.028 | 30,000 | 75,000 | 5,128 | 1,282 | 2,051 | 1,859 |

| 0.875 | 0.035 | 30,000 | 75,000 | 6,522 | 1,630 | 2,609 | 2,316L |

| 0.875 | 0.049 | 30,000 | 75,000 | 9,459 | 2,365 | 3,784 | 3,172 |

| 0.875 | 0.065 | 30,000 | 75,000 | 13,087 | 3,272 | 5,235 | 4,126 |

| 0.875 | 0.083 | 30,000 | 75,000 | 17,560 | 4,390 | 7,024 | 5,152 |

| 0.875 | 0.095 | 30,000 | 75,000 | 20,803 | 5,201 | 8,321 | 5,807 |

| 0.875 | 0.109 | 30,000 | 75,000 | 24,886 | 6,221 | 9,954 | 6,543 |

| 0.875 | 0.120 | 30,000 | 75,000 | 28,346 | 7,087 | 11,339 | 7,100 |

| 1.000 | 0.028 | 30,000 | 75,000 | 4,449 | 1,112 | 1,780 | 1,633 |

| 1.000 | 0.035 | 30,000 | 75,000 | 5,645 | 1,411 | 2,258 | 2,027 |

| 1.000 | 0.049 | 30,000 | 75,000 | 8,149 | 2,037 | 3,259 | 2,796 |

| 1.000 | 0.065 | 30,000 | 75,000 | 11,207 | 2,802 | 4,483 | 3,647 |

| 1.000 | 0.083 | 30,000 | 75,000 | 14,928 | 3,732 | 5,971 | 4,567 |

| 1.000 | 0.095 | 30,000 | 75,000 | 17,593 | 4,398 | 7,037 | 5,159 |

| 1.000 | 0.109 | 30,000 | 75,000 | 20,908 | 5,227 | 8,363 | 5,827 |

| 1.000 | 0.120 | 30,000 | 75,000 | 23,684 | 5,921 | 9,474 | 6,336 |

| 1.000 | 0.134 | 30,000 | 75,000 | 27,459 | 6,865 | 10,984 | 6,963 |

| 1.250 | 0.035 | 30,000 | 75,000 | 4,449 | 1,112 | 1,780 | 1,633 |

| 1.250 | 0.049 | 30,000 | 75,000 | 6,380 | 1,595 | 2,552 | 2,260 |

| 1.250 | 0.065 | 30,000 | 75,000 | 8,705 | 2,176 | 3,482 | 2,958 |

| 1.250 | 0.083 | 30,000 | 75,000 | 11,485 | 2,871 | 4,594 | 3,719 |

| 1.250 | 0.095 | 30,000 | 75,000 | 13,443 | 3,361 | 5,377 | 4,213 |

| 1.250 | 0.109 | 30,000 | 75,000 | 15,843 | 3,961 | 6,337 | 4,776 |

| 1.250 | 0.120 | 30,000 | 75,000 | 17,822 | 4,455 | 7,129 | 5,207 |

| 1.250 | 0.134 | 30,000 | 75,000 | 20,468 | 5,117 | 8,187 | 5,742 |

| 1.500 | 0.035 | 30,000 | 75,000 | 3,671 | 918 | 1,469 | 1,367 |

| 1.500 | 0.049 | 30,000 | 75,000 | 5,243 | 1,311 | 2,097 | 1,896 |

| 1.500 | 0.065 | 30,000 | 75,000 | 7,117 | 1,779 | 2,847 | 2,487 |

| 1.500 | 0.083 | 30,000 | 75,000 | 9,333 | 2,333 | 3,733 | 3,136 |

| 1.500 | 0.095 | 30,000 | 75,000 | 10,878 | 2,719 | 4,351 | 3,559 |

| 1.500 | 0.109 | 30,000 | 75,000 | 12,754 | 3,188 | 5,101 | 4,043 |

| 1.500 | 0.120 | 30,000 | 75,000 | 14,286 | 3,571 | 5,714 | 4,416 |

| 1.500 | 0.134 | 30,000 | 75,000 | 16,315 | 4,079 | 6,526 | 4,881 |

| 1.500 | 0.148 | 30,000 | 75,000 | 18,439 | 4,610 | 7,375 | 5,336 |

| 1.750 | 0.035 | 30,000 | 75,000 | 3,125 | 781 | 1,250 | 1,176 |

| 1.750 | 0.049 | 30,000 | 75,000 | 3,864 | 966 | 1,546 | 1,434 |

| 1.750 | 0.065 | 30,000 | 75,000 | 6,019 | 1,505 | 2,407 | 2,146 |

| 1.750 | 0.083 | 30,000 | 75,000 | 7,860 | 1,965 | 3,144 | 2,711 |

| 1.750 | 0.095 | 30,000 | 75,000 | 9,135 | 2,284 | 3,654 | 3,080 |

| 1.750 | 0.109 | 30,000 | 75,000 | 10,672 | 2,668 | 4,269 | 3,504 |

| 1.750 | 0.120 | 30,000 | 75,000 | 11,921 | 2,980 | 4,768 | 3,832 |

| 1.750 | 0.134 | 30,000 | 75,000 | 13,563 | 3,391 | 5,425 | 4,242 |

| 1.750 | 0.148 | 30,000 | 75,000 | 15,268 | 3,817 | 6,107 | 4,645 |

| 1.750 | 0.165 | 30,000 | 75,000 | 17,430 | 4,357 | 6,972 | 5,124 |

| 2.000 | 0.035 | 30,000 | 75,000 | 2,720 | 680 | 1,088 | 1,032 |

| 2.000 | 0.049 | 30,000 | 75,000 | 3,864 | 966 | 1,546 | 1,434 |

| 2.000 | 0.065 | 30,000 | 75,000 | 5,214 | 1,303 | 2,086 | 1,887 |

| 2.000 | 0.083 | 30,000 | 75,000 | 6,788 | 1,697 | 2,715 | 2,387 |

| 2.000 | 0.095 | 30,000 | 75,000 | 7,873 | 1,968 | 3,149 | 2,715 |

| 2.000 | 0.109 | 30,000 | 75,000 | 9,175 | 2,294 | 3,670 | 3,092 |

| 2.000 | 0.120 | 30,000 | 75,000 | 10,227 | 2,557 | 4,091 | 3,384 |

| 2.000 | 0.134 | 30,000 | 75,000 | 11,605 | 2,901 | 4,642 | 3,751 |

| 2.000 | 0.148 | 30,000 | 75,000 | 13,028 | 3,257 | 5,211 | 4,111 |

| 2.000 | 0.165 | 30,000 | 75,000 | 14,820 | 3,705 | 5,928 | 4,542 |

316 SS Tubing Wall Thickness

| NPS | Tolerance, % | |

| + | – | |

| 1/8-2 1 /2 | 20.0 | 12.5 |

| 3~18, t/D≤ 5% | 22.5 | 12.5 |

| 3~18, t/D> 5% | 15.0 | 12.5 |

| ≥ 20, welded | 17.5 | 12.5 |

| ≥ 20, seamless, t/D≤ 5% | 22.5 | 12.5 |

| ≥ 20, seamless, t/D> 5% | 15.0 | 12.5 |

Diameter Tolerance of 316 Stainless Steel Tube

| NPS | OD Tolerance | |||

| + | – | |||

| inch | mm | inch | mm | |

| 1/8~1 1 /2 > 1 1 /2~4 > 4~8 > 8~18 > 18~26 > 26~34 > 34~48 |

1/64(0.015) 1/32(0.031) 1/16(0.062) 3/32(0.093) 1/8(0.125) 5/32(0.156) 3/16(0.187) |

0.4 0.8 1.6 2.4 3.2 4.0 4.8 |

1/32(0.031) 1/32(0.031) 1/32(0.031) 1/32(0.031) 1/32(0.031) 1/32(0.031) 1/32(0.031) |

0.8 0.8 0.8 0.8 0.8 0.8 0.8 |

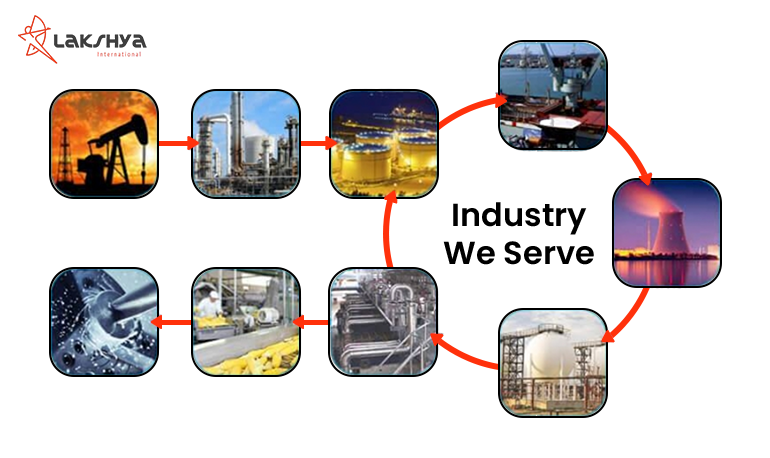

316 Stainless Tube Industrial Applications

Lakshya Steel specializes in manufacturing and exporting high-quality 316 stainless steel tubes, renowned for their durability and performance across multiple industries. Our tubes are used in:

- Fertilizers Industry

- Aerospace Industry

- Nuclear Power Plants

- Chemical Industry

- Oil & Gas Industry

- Refineries

- Petrochemical Industry

- Paper Industry

Our 316 stainless steel tubes are trusted for their strength and reliability in these demanding applications.

Stainless Steel 316 Density

Stainless Steel 316 is valued for its excellent corrosion resistance and durability. With a density of about 8.0 grams per cubic centimeter (g/cm³), this steel is strong and stable. It is commonly used in marine, chemical, and medical applications because it withstands harsh environments well. Whether for piping, fittings, or other uses, the density of Stainless Steel 316 ensures reliability and longevity.

Read More: 316 Stainless Steel Density

Frequently Asked Questions:

What is the difference between 316 and 316L tubing?

316L SS tubing has lower carbon content (max 0.03%) than 316 Stainless steel tube (max 0.08%), offering better corrosion resistance and reduced carbide precipitation, making it ideal for welding and high-stress applications.

What sizes are available for 316 steel tubes?

316 SS tubing sizes typically range from ½ inch to 60 inches in diameter.

Our Products

Our Latest Blogs

Carbon Steel vs Stainless Steel: Key Differences You Need to Know

Picking the right steel for any job in industry is a pretty big deal. Whether you're building huge pipelines, putting up buildings, or making tiny, precise parts, the steel you choose affects how well things work, how long they last, and what they cost. Lots of folks...

What is ERW Pipe and How Are ERW Pipes Made?

When you think about materials that build our world, steel pipes are right up there. They're essential for so many things, from carrying water to supporting buildings. Among the different kinds of steel pipes, ERW pipe – which stands for Electric Resistance Welded...

What is an Alloy? A Complete Guide to Alloy Metal

Ever think about alloys all around you. Strong car wheels for example. Or kitchen tools that don't rust. Yes, alloys are everywhere. But many people do not really know what is an alloy. In this blog, we will discuss everything about alloys. We will talk about what...

Related Products

- Stainless Steel 304 Single Slotted Pipe

- Stainless Steel 304 Double Slotted Pipe

- Stainless steel 304 fittings

- Stainless Steel 304 Components

- Stainless Steel 309 Rod/Bar

- Stainless Steel 309 Hex Bar

- Stainless Steel 309 Square Bar

- Stainless Steel 309 Welded Pipes

- Stainless Steel 309 Plates Sheet

- Stainless steel 309 fittings

- Stainless Steel 309 Components

- Stainless Steel 310 Rod / Bar

- Stainless steel 310 Hex Bars

- Stainless Steel 310 Square Bar

- Stainless Steel 310 Welded Pipes

- Stainless Steel 310 Plates/Sheet

- Stainless Steel 310 Seamless Pipes

- Stainless steel 310 Welded Tubes

- Stainless steel 310 fittings

- Stainless steel 310 channels

- Stainless steel 310 H Beam

- Stainless steel 310 I Beam

- Stainless steel 310 seamless tubes

- Stainless Steel 310 Components

- Stainless Steel 316 / 316Ti Flanges

- Stainless Steel 316 / 316Ti Rod

- Stainless Steel 316 / 316Ti Hex Bars

- Stainless Steel 316 / 316Ti Square Bars

- Stainless Steel 316 / 316Ti Seamless Pipes

- Stainless Steel 316 / 316Ti Welded Pipes

- Stainless Steel 316 / 316Ti Plates

- Stainless Steel 316 / 316Ti Welded Tubes

- Stainless Steel 316 / 316Ti Seamless Tubes

- Stainless Steel 316 / 316Ti Flat Bars

- Stainless Steel 316 / 316Ti Angles

- Stainless Steel 316 / 316Ti Channels

- Stainless Steel 316 / 316Ti H Beams

- Stainless Steel 316 / 316Ti I Beam

- Stainless Steel 316 / 316Ti Pipe Fittings

- Stainless Steel 316 Single Slotted Pipe

- Stainless Steel 316 Double Slotted Pipe

- Stainless Steel 316/316Ti Components

- Stainless Steel 317L Flanges

- Stainless Steel 317L Rod/Bar

- Stainless Steel 317L Hex Bar

- Stainless steel 317L Square Bar

- Stainless Steel 317L Plates/Sheet

- Stainless steel 317L channels

- Stainless steel 317L H Beam

- Stainless steel 317L I Beam

- Stainless steel 317L fittings

- Stainless Steel 317L Components

- Stainless Steel 321 / 347 Flanges

- Stainless Steel 321/347 Rod/Bar

- Stainless Steel 321/347 Hex Bar

- Stainless Steel 321/347 Square Bar

- Stainless Steel 321/347 Seamless Pipes

- Stainless Steel 321/347 Welded Pipes

- Stainless Steel 321 / 347 Pipe Fittings

- Stainless Steel 321/347 Plates/Sheet

- Stainless steel 321 / 347 Welded Tubes

- Stainless steel 321 / 347 seamless tubes

- Stainless steel 321 / 347 channels

- Stainless steel 321 / 347 H Beam

- Stainless steel 321 / 347 I Beam

- Stainless Steel 321 / 347 Components

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 Flange

- Stainless Steel 409/409M/409L/410/430/430F/431/439/441 Rod/Bars

- Stainless Steel 409/409M/409L/410/430/430F/431/439/441 Hex Bar

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 Square Bar

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 Welded Pipes

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 Sheet /Plates/Coil

- Stainless Steel 409/409M/409L/410/430/430F/431/439/441 Welded tubes

- Stainless Steel 409/409M/409L/410/430/430F/431/439/441 Channel

- Stainless Steel 409/409M/409L/410/430/430F/431/439/441 H Beam

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 I Beam

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 Components

- Stainless Steel 420/ 420B & 420C Rod/Bar

- Stainless steel 420 / 420B & 420C hex bars

Send Us Message

Got a question? We'd love to hear from you. Send us a message & we'll respond as soon as possible.