Stainless Steel 304 Products

Stainless Steel 304 Pipe

Table of Content

- 304 Stainless Pipe Manufacturer & Supplier

- Trusted Stainless Steel 304 Pipes Manufacturer

- Shapes & Dimensions of 304 SS Pipe

- Product Range – Types of SS 304 Pipes We Offer

- Specifications – Technical Standards for SS 304 Pipes

- Chemical Composition – Stainless Steel 304

- Mechanical Properties 304 Stainless Steel Pipes

- Stainless Pipe 304 Physical Properties

- Stainless Steel 304 Pipe Equivalent Grades

- SS 304 Welded Pipe Schedule Chart

- Stainless Steel 304 Pipe Sizes

- SS 304 Pipe Weight Chart

- Stainless Steel 304 Pipe Pressure Rating

- Stainless Pipe 304 Tolerance Chart

- Stainless Steel 304 Pipe Types

- Applications of 304 SS Pipes

- Global Exporter – Indian Excellence, Worldwide Reach

- Quality Policy – Certified Reliability You Can Trust

- Packaging Information – Safe, Standardized Shipping

- FAQs

Stainless Steel 304 Pipes Manufacturer & Supplier in Mumbai, India

Stainless Steel 304 Pipe

SS 304 Seamless Pipe

SS 304 Sch 40 Pipe

Trusted Stainless Steel 304 Pipes Manufacturer

Lakshya Steel is a trusted manufacturer and supplier of high-quality stainless steel products, specializing in 304 stainless steel pipes. Renowned for their strength and versatility, our SS 304 pipes are made from austenitic stainless steel containing 18% chromium and 8% nickel. These pipes are engineered to withstand high pressures and temperatures, making them ideal for a wide range of applications across commercial, industrial, and domestic sectors.

We offer an extensive selection of 304 stainless steel pipes, including both seamless and welded options, all manufactured to comply with ASTM A312 and A358 standards. Our pipes come in a variety of sizes, with nominal bore sizes ranging from ½ inch to 16 inches for 304 stainless steel seamless pipes, ½ inch to 24 inches for 304 stainless steel welded pipes, and 6 inches to 100 inches for EFW pipes. Whether you need round, square, rectangular, or hydraulic types, we have the perfect solution for your specific requirements.

The SS 304 sch 40 pipe thickness and sizes range from 1/8 inch to 30 inches, offering flexibility for various applications. Our SS UNS S30400 ERW pipes feature a minimum yield strength of 205 MPa and a minimum tensile strength of 515 MPa, ensuring optimal performance even in demanding conditions.

In addition to our top-quality products, we offer competitive pricing for SS 304 pipe price per kg and SS 304 pipe price per meter, providing cost-effective solutions for your project needs. If you’re looking for premium stainless steel 304 seamless pipes or welded pipes, contact us today for more information about our products and pricing. Let Lakshya Steel be your trusted partner for all your 304 stainless pipe needs!

Check Out Our Related Blog On – Stainless Steel 304 Pipe Price List

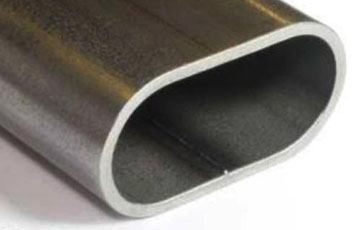

Shapes & Dimensions of 304 SS Pipe

Lakshay Steel manufactures Stainless Steel 304 Pipes in a variety of shapes and sizes to meet the requirements of industries globally. Whether the need is for mechanical components, structural applications, or high pressure, our products are designed to be consistent, reliable, and thoroughly compatible.

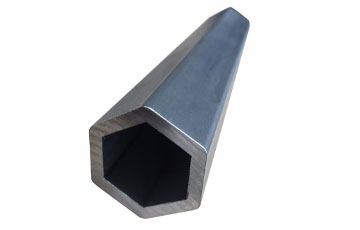

Available Shapes:.

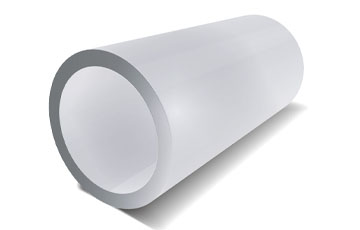

- Round Pipes – The most commonly used form for fluid transport and structural applications.

- Square Pipes – Ideal for architectural and fabrication use.

- Rectangular Pipes – Preferred for frames, supports, and custom design projects.

Dimensional Range:

- Outside Diameter: 6mm to 610mm

- Wall Thickness: 0.5mm to 30mm

- Length: Single random, double random, and custom cut lengths

- Standards: ASTM A312, A213, A249, EN, DIN, JIS

Product Range – Types of SS 304 Pipes We Offer

Our SS 304 Pipe Types Include

- SS 304 Seamless Pipes

Manufactured using solid billets, these pipes are ideal for high-pressure and high-temperature applications in industries like oil & gas, power generation, and refineries. - SS 304 Welded Pipes

Cost-effective and strong, these pipes are produced by welding stainless steel strips and are suitable for structural and low-pressure applications. - SS 304 ERW Pipes (Electric Resistance Welded)

Commonly used in architectural and engineering sectors for their smooth finish and excellent mechanical strength. - SS 304 Fabricated Pipes

Customized solutions for specific client requirements and complex assemblies. - SS 304 Round Pipes

Widely used for fluid transport, decorative purposes, and structural applications. - SS 304 Square Pipes

Popular in furniture, framework, and architectural structures due to their clean edges and modern appeal. - SS 304 Rectangular Pipes

Used in construction and fabrication where precise dimensions are required. - SS 304 Polished Pipes (Mirror/Matte Finish)

These aesthetic-grade pipes are ideal for visible applications such as railings, kitchen equipment, and interior design.

Specifications – Technical Standards for SS 304 Pipes

No matter the need for SS 304 pipes, you can find within our product range SS 304 pipes for industrial, structural or sanitary applications, in an extensive range of technical configurations.

| Standard | ASTM A312 / A213 / A249 / A269 / A358 / A554 |

| Grades | SS 304, 304L (Low Carbon) |

| Form | Seamless, Welded, ERW, Fabricated, LSAW, CDW |

| Outer Diameter | 6 mm to 630 mm |

| Wall Thickness | 0.5 mm to 30 mm |

| Schedule | SCH 5S, 10S, 40S, 80S, 160S, XXS |

| Length | Single Random, Double Random & Custom Cut Lengths |

| Pipe Ends | Plain End (PE), Beveled End (BE), Threaded End (TE) |

| Finish | Annealed & Pickled, Polished (180, 320, 400 grit), Bright |

| Tolerance | As per ASTM A999 / EN / DIN specifications |

| Certification | ISO 9001:2015, PED, EN 10204 3.1, Mill Test Certificate |

Key Features:

- High corrosion resistance in oxidizing environments

- Excellent forming and welding characteristics

- Suitable for high-temperature and high-pressure conditions

- Non-magnetic in annealed condition

- Hygienic and easy to clean surface finish

Chemical Composition – Stainless Steel 304

At Lakshay Steel, we guarantee that every manufactured batch of SS 304 pipes uses raw materials that exceed international chemical specifications, for consistent quality and longevity.

| Element | Minimum (%) | Maximum (%) |

| Chromium (Cr) | 18.0 | 20.0 |

| Nickel (Ni) | 8.0 | 10.5 |

| Carbon (C) | — | 0.08 |

| Manganese (Mn) | — | 2.0 |

| Silicon (Si) | — | 1.0 |

| Phosphorus (P) | — | 0.045 |

| Sulfur (S) | — | 0.030 |

| Nitrogen (N) | — | 0.10 |

| Iron (Fe) | Balance | — |

Why This Composition Matters

- Chromium & Nickel content delivers exceptional corrosion and oxidation resistance.

- Low Carbon ensures minimal carbide precipitation, maintaining corrosion resistance after welding.

- Manganese & Silicon improve strength and deoxidation during manufacturing.

- Nitrogen enhances mechanical strength without compromising ductility.

Mechanical Properties 304 Stainless Steel Pipes

Our Stainless Steel 304 pipes are made according to the relevant international standards, with good tensile strength and yield strength, which are fundamental characteristics to ensure the longevity of your project. The elongation percentage is also high, the Brinell Hardness rating means it is easy to weld, build and install into many systems.

Below are the typical mechanical properties of SS 304 Pipes:

| Property | Value |

| Tensile Strength (UTS) | 515 – 750 MPa |

| Yield Strength (0.2% Proof) | ≥ 205 MPa |

| Elongation | ≥ 40% |

| Hardness (Brinell HB max.) | 201 |

| Modulus of Elasticity | ~193 GPa |

| Density | 7.93 g/cm³ |

Stainless Pipe 304 Physical Properties

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (m/m/0C) | Thermal Conductivity (W/m.K) | Specific Heat 0-1000C (J/kg.K) | Electrical Resistivity (n.m) | |||

| 0-1000C | 0-3150C | 0-5380C | at 1000C | at 5000C | |||||

| 304 | 8000 | 193 | 17.2 | 17.8 | 18.4 | 16.2 | 21.5 | 500 | 720 |

Stainless Steel 304 Pipe Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | AFNOR | BS | GOST | EN |

| SS 304 | 1.4301 | S30400 | SUS 304 | Z7CN18‐09 | 304S31 | 08Х18Н10 | X5CrNi18-10 |

SS 304 Welded Pipe Schedule Chart

| 1/8″ IPS(.405″O. D.) | 3 1/2″ IPS( 4.000″O. D.) |

| SCH 40, 80 | SCH 10, 40, 80, 160, XXH |

| 1/4″ IPS(.540″O. D.) | 4″ IPS(4.500″O. D.) |

| SCH 10, 40, 80 | SCH 10, 40, 80, 160, XXH |

| 3/8″ IPS(.675″O. D.) | 5″ IPS( 5.563″O. D.) |

| SCH 10, 40, 80 | SCH 10, 40, 80, 160, XXH |

| 1/2″ IPS(.840″O. D.) | 6″ IPS(6.625″O. D.) |

| SCH 5, 10, 40, 80, 160, XXH | SCH 5, 10, 40, 80, 120, 160, XXH |

| 3/4″ IPS(1.050″O. D.) | 8 ” IPS(8.625″O. D.) |

| SCH 10, 40, 80, 160, XXH | SCH 5, 10, 40, 80, 120, 160, XXH |

| 1″ IPS:(1.315′O. D.) | 10″ IPS(10.750″O. D.) |

| SCH 5, 10, 40, 80, 160, XXH | SCH 10, 20, 40, 80 (.500), TRUE 80(.500) |

| 1-1/4″ IPS(1.660″O. D.) | 12″ IPS(12.750″O. D.) |

| SCH 10, 40, 80, 160, XXH | SCH 10, 20, 40(.375), TRUE40(.406), SCH80(.500) |

| 1-1/2″ IPS(1.900″O. D.) | 14″ IPS(14.000″O. D.) |

| SCH 10, 40, 80, 160, XXH | SCH10 (.188), SCH40 (.375) |

| 2″ IPS(2.375″O. D.) | 16″ IPS(16.000″O. D.) |

| SCH 10, 40, 80, 160, XXH | SCH10(.188), SCH40(.375) |

| 2 1/2″ IPS(2.875″O. D.) | 18″ IPS (18.000″O. D.) |

| SCH 10, 40, 80, 160, XXH | SCH-40 (.375) |

| 3″ IPS( 3.500″O. D.) | |

| SCH 5, 10, 40, 80, 160, XXH |

Stainless Steel 304 Pipe Sizes

| Wall Thickness | Stainless Steel 304 Tube Sizes ( O.D.) Sizes ( O.D.) |

| .010 | 1/16″ , 1/8″ , 3/16″ |

| .020 | 1/16″ , 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ |

| .012 | 1/8″ |

| .016 | 1/8″ , 3/16″ |

| .028 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 3/4″ , 1″ , 1 1/2″ , 2″ |

| .035 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 7/16″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .049 | 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/8″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .065 | 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 3/4″ , 2″ , 2 1/2″ , 3″ |

| .083 | 1/4″ , 3/8″ , 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 7/8″ , 2″ , 2 1/2″ ,3″ |

| .095 | 1/2″ , 5/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .109 | 1/2″ , 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .120 | 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 2 1/4″ , 2 1/2″ , 3″ |

| .125 | 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 3″ , 3 1/4″ |

| .134 | 1″ |

| .250 | 3″ |

| .375 | 3 1/2″ |

SS 304 Pipe Weight Chart

| Nominal Pipe Size (NPS) | Outside Diameter (OD) | SCH 40 S | SCH 10 S | SCH 5 S | SCH 20 S | SCH 80 S | SCH 160 S | XXS | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | inch | mm | WT mm | Kg/m Weight | WT mm | Kg/m Weight | WT mm | Kg/m Weight | WT mm | Kg/m Weight | WT mm | Kg/m Weight | WT mm | Kg/m Weight | WT mm | Kg/m Weight |

| 3 | 1/8 | 10.3 | 1.73 | 00.37 | 1.24 | 00.28 | 1.2 | 00.20 | 1.5 | 00.33 | 2.41 | 00.47 | – | – | – | – |

| 6 | 1/4 | 13.7 | 2.24 | 00.630 | 1.65 | 00.49 | 1.2 | 00.37 | 2.00 | 00.58 | 3.02 | 00.80 | – | – | – | – |

| 10 | 3/8 | 17.1 | 2.31 | 00.840 | 1.65 | 00.63 | 1.2 | 00.47 | 2.00 | 00.74 | 3.20 | 1.10 | – | – | – | – |

| 15 | 1/2 | 21.3 | 2.77 | 1.27 | 2.11 | 1.00 | 1.65 | 00.80 | 2.30 | 1.07 | 3.73 | 1.62 | 4.75 | 1.94 | 7.47 | 2.55 |

| 20 | 3/4 | 26.7 | 2.87 | 1.69 | 2.11 | 1.28 | 1.65 | 1.03 | 2.55 | 1.52 | 3.91 | 2.20 | 5.56 | 2.90 | 7.82 | 3.64 |

| 25 | 1 | 33.4 | 3.38 | 2.50 | 2.77 | 2.09 | 1.65 | 1.30 | 2.55 | 1.94 | 4.55 | 3.24 | 6.35 | 4.24 | 9.09 | 5.45 |

| 32 | 1.1/4 | 42.2 | 3.56 | 3.39 | 2.77 | 2.70 | 1.65 | 1.65 | 3.00 | 2.90 | 4.85 | 4.47 | 6.35 | 5.61 | 9.70 | 7.77 |

| 40 | 1.1/2 | 48.3 | 3.68 | 4.05 | 2.77 | 3.11 | 1.65 | 1.91 | 3.00 | 3.55 | 5.08 | 5.41 | 7.14 | 7.25 | 11.1 | 10.18 |

| 50 | 2 | 60.3 | 3.91 | 5.44 | 2.77 | 3.93 | 1.65 | 2.40 | 3.00 | 4.24 | 5.54 | 7.48 | 8.74 | 11.11 | 11.07 | 13.44 |

| 65 | 2.1/2 | 73.0 | 5.16 | 8.63 | 3.05 | 5.26 | 2.11 | 3.69 | 4.00 | 6.81 | 7.01 | 11.41 | 9.53 | 14.91 | 14.02 | 20.39 |

| 80 | 3 | 88.9 | 5.49 | 11.29 | 3.05 | 6.45 | 2.11 | 4.51 | 4.00 | 8.37 | 7.62 | 15.27 | 11.1 | 21.30 | 15.24 | 27.68 |

| 100 | 4 | 114.3 | 6.02 | 16.07 | 3.05 | 8.36 | 2.11 | 5.84 | 4.50 | 12.18 | 8.56 | 22.32 | 13.49 | 33.54 | 17.12 | 41.03 |

| 125 | 5 | 141.3 | 6.55 | 21.8 | 3.40 | 11.57 | 2.77 | 9.47 | 5.00 | 16.80 | 9.53 | 30.97 | 15.88 | 49.11 | 19.05 | 57.43 |

| 150 | 6 | 168.3 | 7.11 | 28.26 | 3.40 | 13.84 | 2.77 | 11.32 | 6.35 | 25.36 | 10.97 | 42.56 | 18.25 | 67.53 | 21.95 | 79.22 |

| 200 | 8 | 219.1 | 8.18 | 42.55 | 3.76 | 19.96 | 2.77 | 14.79 | 6.35 | 33.31 | 12.7 | 64.64 | 23.01 | 111.27 | 22.23 | 107.92 |

| 250 | 10 | 273.1 | 9.27 | 60.31 | 4.19 | 27.78 | 3.40 | 22.63 | 6.35 | 41.77 | 12.7 | 96.01 | 28.58 | 172.33 | 25.40 | 155.15 |

| 300 | 12 | 323.8 | 9.53 | 73.88 | 4.57 | 36.00 | 3.96 | 31.25 | 6.35 | 49.7 | 12.7 | 132.05 | 33.32 | 238.76 | 25.40 | 186.97 |

Stainless Steel 304 Pipe Pressure Rating

| NPS | Outside Diameter | Wall Thickness | Weight | Weight | |||

| in | mm | in | mm | Sched | kg/Mtr | Lb/ft | |

| 1/2″ | 0.840 | 21 | 0.109 | 2.769 | 40 STD | 1.268 | 0.851 |

| 0.147 | 3.734 | 80 STD | 1.621 | 1.088 | |||

| 3/4″ | 1.050 | 27 | 0.113 | 2.870 | 40 STD | 1.684 | 1.131 |

| 0.154 | 3.912 | 80 STD | 2.195 | 1.474 | |||

| 1″ | 1.315 | 33 | 0.133 | 3.378 | 40 STD | 2.501 | 1.679 |

| 0.179 | 4.547 | 80 STD | 3.325 | 2.172 | |||

| 1 1/4″ | 1.660 | 42 | 0.140 | 3.556 | 40 STD | 3.385 | 2.273 |

| 0.191 | 4.851 | 80 STD | 4.464 | 2.997 | |||

| 1 1/2″ | 1.900 | 48 | 0.145 | 3.683 | 40 STD | 4.048 | 2.718 |

| 0.200 | 5.080 | 80 STD | 5.409 | 3.361 | |||

| 2″ | 2.375 | 60 | 0.154 | 3.912 | 40 STD | 5.441 | 3.653 |

| 0.218 | 5.537 | 80 STD | 7.480 | 5.022 | |||

| 2 1/2″ | 2.875 | 73 | 0.203 | 5.516 | 40 STD | 8.629 | 5.793 |

| 0.276 | 7.010 | 80 STD | 11.411 | 7.661 | |||

| 3″ | 3.500 | 89 | 0.216 | 5.486 | 40 STD | 11.284 | 7.576 |

| 0.300 | 7.620 | 80 STD | 15.272 | 10.253 | |||

| 4″ | 4.500 | 114 | 0.237 | 6.020 | 16.073 | 10.790 | |

| 0.337 | 8.560 | 22.318 | 14.983 | ||||

| 6″ | 6.625 | 168 | 0.188 | 4.775 | 19.252 | 12.924 | |

| 0.203 | 5.516 | 20.739 | 13.923 | ||||

| 0.219 | 5.563 | 22.318 | 14.983 | ||||

| 0.250 | 6.350 | 25.354 | 17.021 | ||||

| 0.280 | 7.112 | 40 STD | 58.263 | 18.974 | |||

| 0.312 | 7.925 | 31.334 | 21.036 | ||||

| 0.375 | 9.525 | 37.285 | 25.031 | ||||

| 0.432 | 10.973 | 80 XHY | 42.561 | 28.573 | |||

| 0.500 | 12.700 | 48.719 | 32.708 | ||||

| 8″ | 8.625 | 219 | 0.188 | 4.775 | 25.233 | 16.940 | |

| 0.203 | 5.156 | 27.198 | 18.259 | ||||

| 0.219 | 5.563 | 29.286 | 19.661 | ||||

| 0.250 | 6.350 | 20 | 33.308 | 22.361 | |||

| 0.277 | 7.036 | 30 | 36.786 | 24.696 | |||

| 0.322 | 8.179 | 40 | 42.352 | 28.554 | |||

| 0.375 | 9.525 | 49.216 | 33.041 | ||||

| 0.406 | 10.312 | 60 | 53.085 | 35.638 | |||

| 0.500 | 12.700 | 80 XHY | 64.627 | 43.388 | |||

| 10″ | 10.750 | 273 | 0.188 | 4.775 | 31.588 | 21.207 | |

| 0.219 | 5.563 | 36.689 | 24.631 | ||||

| 0.250 | 6.350 | 20 | 41.759 | 28.035 | |||

| 0.307 | 7.798 | 30 | 51.002 | 34.240 | |||

| 0.344 | 8.738 | 56.946 | 38.231 | ||||

| 0.365 | 9.271 | 40 STD | 63.301 | 40.483 | |||

| 0.438 | 11.125 | 71.852 | 48.238 | ||||

| 0.500 | 12.700 | 60 XHY | 81.530 | 54.735 | |||

| 0.594 | 15.088 | 80 | 95.969 | 64.429 | |||

| 12″ | 12.750 | 324 | 0.188 | 4.775 | 37.570 | 25.222 | |

| 0.219 | 5.563 | 43.657 | 29.309 | ||||

| 0.250 | 6.350 | 49.713 | 33.375 | ||||

| 0.281 | 7.137 | 55.739 | 37.420 | ||||

| 0.312 | 7.925 | 61.735 | 41.445 | ||||

| 0.375 | 9.525 | 73.824 | 49.562 | ||||

| 0.406 | 10.312 | 79.727 | 53.525 | ||||

| 0.500 | 12.700 | 97.438 | 65.415 | ||||

| 0.562 | 14.275 | 108.966 | 73.154 | ||||

| 14″ | 14.000 | 356 | 0.188 | 4.775 | 41.308 | 27.732 | |

| 0.219 | 5.563 | 48.012 | 32.233 | ||||

| 0.250 | 6.350 | 20 | 54.685 | 36.713 | |||

| 0.281 | 7.137 | 61.327 | 41.172 | ||||

| 0.312 | 7.925 | 67.939 | 45.611 | ||||

| 0.375 | 9.525 | STD | 81.281 | 54.568 | |||

| 0.438 | 11.125 | 40 | 94.498 | 63.441 | |||

| 0.500 | 12.700 | XHY | 107.381 | 72.090 | |||

| 0.625 | 15.875 | 132.983 | 89.278 | ||||

| 16” | 16.000 | 406 | 0.188 | 4.775 | 47.290 | 21.748 | |

| 0.219 | 5.563 | 54.980 | 36.910 | ||||

| 0.250 | 6.350 | 10 | 62.639 | 42.053 | |||

| 0.281 | 7.137 | 70.268 | 47.174 | ||||

| 0.312 | 7.925 | 20 | 77.866 | 52.275 | |||

| 0.344 | 8.738 | 85.677 | 57.519 | ||||

| 0.375 | 9.525 | 30

STD |

93.213 | 62.578 | |||

| 0.438 | 11.125 | 108.433 | 72.797 | ||||

| 0.500 | 12.700 | 40

XHY |

123.289 | 82.770 | |||

| 18″ | 18.000 | 457 | 0.219 | 5.563 | 61.948 | 41.588 | |

| 0.250 | 6.350 | 70.593 | 47.393 | ||||

| 0.281 | 7.137 | 79.208 | 53.176 | ||||

| 0.312 | 7.925 | 20 | 87.792 | 58.939 | |||

| 0.375 | 9.525 | STD | 105.144 | 70.588 | |||

| 0.438 | 11.125 | 30 | 122.369 | 82.152 | |||

| 0.500 | 12.700 | XHY | 139.198 | 93.450 | |||

| 0.562 | 14.275 | 40 | 155.904 | 104.666 | |||

| 0.625 | 15.875 | 172.754 | 115.978 | ||||

| 20″ | 20.000 | 508 | 0.250 | 6.350 | 78.547 | 52.733 | |

| 0.282 | 7.163 | 88.458 | 59.386 | ||||

| 0.312 | 7.925 | 97.719 | 65.604 | ||||

| 0.375 | 9.525 | 20 STD | 117.075 | 78.598 | |||

| 0.438 | 11.125 | 136.305 | 91.508 | ||||

| 0.500 | 12.700 | 30 XHY | 155.106 | 104.130 | |||

| 0.594 | 15.088 | 40 | 183.378 | 123.110 | |||

| 0.625 | 15.875 | 192.640 | 129.328 | ||||

| 0.688 | 17.475 | 211.368 | 141.901 | ||||

| 24″ | 24.000 | 610 | 0.250 | 6.350 | 94.456 | 63.413 | |

| 0.281 | 7.137 | 106.029 | 71.183 | ||||

| 0.312 | 7.925 | 117.573 | 18.932 | ||||

| 0.375 | 9.525 | 20 STD | 140.938 | 64.618 | |||

| 0.438 | 11.125 | 164.176 | 110.219 | ||||

| 0.500 | 12.700 | XHY | 186.923 | 125.490 | |||

| 0.625 | 15.875 | 232.410 | 156.028 | ||||

| 0.688 | 17.475 | 40 | 255.148 | 171.293 | |||

| 0.750 | 19.050 | 277.401 | 186.233 | ||||

| 30″ | 30.000 | 762 | 0.250 | 6.350 | 118.318 | 79.433 | |

| 0.281 | 7.137 | 132.851 | 89.189 | ||||

| 0.312 | 7.925 | 10 | 147.353 | 98.925 | |||

| 0.375 | 9.525 | STD | 176.731 | 118.648 | |||

| 0.438 | 11.125 | 205.983 | 138.286 | ||||

| 0.500 | 12.700 | 20 XHY | 234.647 | 157.530 | |||

| 0.625 | 15.875 | 30 | 292.066 | 196.078 | |||

| 0.688 | 17.475 | 320.817 | 215.380 | ||||

| 0.750 | 19.050 | 348.988 | 234.293 | ||||

| 36″ | 36.000 | 914 | 0.250 | 6.350 | 142.180 | 95.453 | |

| 0.281 | 7.137 | 159.672 | 107.196 | ||||

| 0.312 | 7.925 | 10 | 177.133 | 118.918 | |||

| 0.375 | 9.525 | STD | 215.525 | 142.678 | |||

| 0.438 | 11.125 | 247.790 | 166.353 | ||||

| 0.500 | 12.700 | 20 XHY | 282.372 | 198.570 | |||

| 0.625 | 15.875 | 351.723 | 236.128 | ||||

| 0.688 | 17.475 | 386.487 | 259.467 | ||||

| 0.750 | 19.050 | 420.576 | 282.353 | ||||

| 42″ | 42.000 | 1067 | 0.312 | 7.925 | 206.914 | 138.911 | |

| 0.375 | 9.525 | STD | 248.319 | 166.708 | |||

| 0.500 | 12.700 | XHY | 33.097 | 221.610 | |||

| 0.750 | 19.050 | 492.163 | 330.413 | ||||

| 48″ | 48.000 | 1219 | 0.375 | 9.525 | STD | 284.112 | 190.738 |

| 0.438 | 11.125 | 331.404 | 222.487 | ||||

| 0.500 | 12.700 | XHY | 377.822 | 253.650 | |||

| 0.750 | 19.050 | 563.750 | 378.473 | ||||

| 0.875 | 22.225 | 655.969 | 440.383 | ||||

Stainless Pipe 304 Tolerance Chart

| Standard | Manufacturing Method | Wall Thickness Tolerance | OD Tolerance | Others | |

| Outer Diameter (mm) | Class | ||||

| EN10216-5 | Hot Finished Stainless Steel 304 Seamless Pipe | +22.5%T,-15%T | 219.1~610 | D1 | T/D≤0.05 |

| T1 | T/D≤0.09 | ||||

| T2 | T/D>0.09 | ||||

| T1 | 30~219.1 | D2 | |||

| T2 | |||||

| Cold Finished 304 Stainless Steel Seamless Pipe | T3 | ≤219.1 | D3 | ||

| T4 | D4 | Agreement | |||

| EN10297-2 | Hot Finished 304 Grade Stainless Steel Seamless Pipe | T1 | D1 | ||

| T2 | D2 | Agreement | |||

| Cold Finished SS 304 Seamless Pipe | T3 | D3 | |||

| T4 | D4 | Agreement | |||

| EN10217-7 | Stainless Steel 304 Welded Pipe | T3 | >168.3 | D2 | |

| T3 | ≤168.3 | D3 | |||

| T3 | D4 | Agreement | |||

| EN10296-2 | 304 Stainless Steel Welded Pipe | T3 | >168.3 | D2 | |

| T3 | ≤168.3 | D3 | |||

| T3 | ≤114.3 | D4 | Agreement | ||

| EN10312 | 304 Grade Stainless Steel Welded Pipe | T3 | Series 1 | D4 | T=0.6~2 Mm |

| T3 – T4 | Series 2 | D3 – D4 | T=1~3 Mm | ||

Stainless Steel 304 Pipe Types

SS 304 Rectangular Pipe

SUS 304 304 Hollow Pipe

SS 304 Square Pipe

INOX 304 Exhaust Pipe

Stainless Steel 304 Oval Pipe

SS 304 Round Pipe

SS 304 Hexgonal Pipe

DIN 1.4301 Seamless Pipe

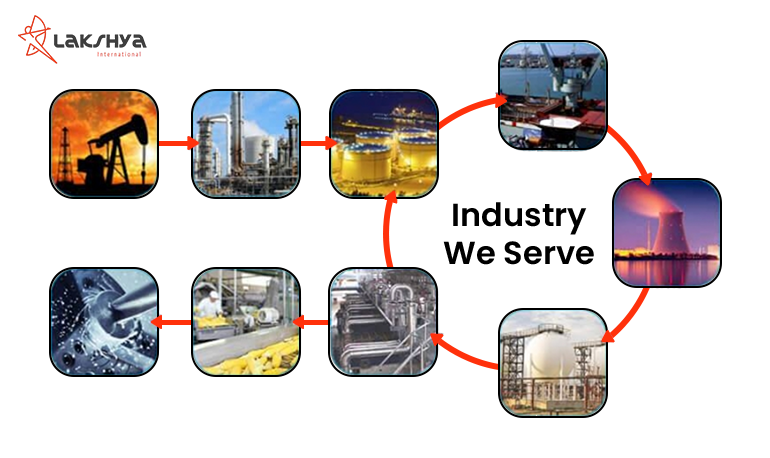

Applications of 304 SS Pipes

Our 304 SS Pipes are ideal for industries such as:

- Oil & Gas Industry

Used for transportation of oil, natural gas, and petrochemical fluids due to excellent resistance to high pressure and corrosive media. - Construction & Infrastructure

Widely used in structural supports, frameworks, handrails, and scaffolding due to their high strength and weldability. - Automotive & Transportation

Applied in exhaust systems, fuel lines, and vehicle body components where high-temperature and corrosion resistance are essential. - Water Treatment & Plumbing

Perfect for freshwater and wastewater systems, pipelines, and sanitary fittings due to their hygienic properties and resistance to scaling. - Pharmaceutical & Food Processing

Used in cleanroom piping, food-grade conveyors, and sanitary tubing where hygiene, non-reactivity, and easy sterilization are critical. - Chemical & Petrochemical Industry

SS 304 pipes are resistant to various chemicals and acids, making them suitable for processing units, reactors, and storage systems. - Architecture & Interior Design

Polished SS 304 pipes are commonly used for decorative railings, cladding, and furniture because of their attractive appearance and durability. - Lakshay Steel’s SS 304 Pipes have been performance-tested across these industries and continue to meet the highest standards of reliability and application-specific demands.

Global Exporter – Indian Excellence, Worldwide Reach

Our SS 304 pipes meet global specifications including ASTM, ASME, DIN and EN or other regulatory requirements to facilitate its use in critical application across Industries such as Oil & Gas, Petrochemicals, Pharmaceuticals, Food Processing and Construction.

Countries We Export To:

- United States

- Germany

- United Kingdom

- Saudi Arabia

- UAE

- South Africa

- Singapore

- Australia

- Brazil

- and many more.

Quality Policy – Certified Reliability You Can Trust

Quality is not only our norm here at Lakshay Steel; it is our commitment. As a well-known Stainless Steel 304 Pipes Manufacturer, our quality policy is founded upon the cornerstones of precision engineering, international compliance, and assurance of total customer satisfaction.

We closely follow quality regulations that comply with globally accepted norms, such as ISO 9001:2015, ensuring that each SS 304 pipe produced is completely checked for quality as much as possible at every stage of production, from the selection of raw material to overall dispatch. Our in-house testing services are equipped with the latest and most suitable equipment for non-destructive testing (NDT) testing, chemical analysis, mechanical testing, and dimensional verification.

Key Highlights of Our Quality Commitment:

- 100% traceability of materials with Mill Test Certificates (MTC)

- Compliance with ASTM, ASME, DIN, and EN standards

- Continuous audits and quality control systems

- Skilled QC team monitoring every production batch

- Third-party inspection available upon request (e.g., TUV, BV, SGS)

Packaging Information – Safe, Standardized Shipping

Key Features of Our Packaging Process:

- Protective End Caps: Each pipe is sealed with plastic end caps to prevent dust, moisture, and physical damage during handling.

- HDPE/LDPE Wrapping: Pipes are wrapped in moisture-resistant plastic or LDPE/HDPE sheets to shield them from environmental elements.

- Wooden Crates or Bundles: Depending on customer requirements and destination, we offer:

- Wooden boxes or crates for export shipments (fumigated and seaworthy)

- Steel strip-bound bundles for domestic deliveries

- Barcoding & Labeling: All packages are labeled with product details, heat number, size, grade, and batch for easy traceability.

- Customized Packing: On request, we offer customized packing solutions to comply with specific project or country requirements.

Enquire Today for Your Finned Pipe Needs! Get Your Custom Quote!

Frequently Asked Questions:

What is 304 stainless steel pipe?

What is the price of 304 steel pipe?

Which is better, 304 or 316 stainless steel?

Is 304 more expensive than 316?

Which grade of stainless steel is best?

Taiwan, Mexico, Iran, Namibia, Afghanistan, Netherlands, Nepal, Ireland, Libya, Morocco, Iran, Switzerland, Finland, Slovakia, Pakistan, Australia, Serbia, Angola, China, Philippines, Czech Republic, Belgium, Estonia, Costa Rica, Croatia, Sweden, Venezuela, Colombia, India, Belarus, Jordan, Azerbaijan, Mongolia, Vietnam, Ghana, Iraq, Algeria, Puerto Rico, New Zealand, Singapore, Indonesia, Ukraine, Israel, Mexico, Hong Kong, Bhutan, Germany, Brazil, Plan, Yemen, Malasiya, USA, Cambodia, Laos, Uganda, Tanzania, Sudan, Democratic Republic of Congo, zambia, Ethiopia, Brunei, Madagascar, Niger, Mali, Bangladesh, Bolivia, United States, Ecuador, Lebanon, Italy, South Korea, Denmark, Norway, Sri Lanka, Zimbabwe, Japan, Yemen, Oman, Portugal, Lithuania, Canada, Macau, Bahrain, Austria, Bulgaria, Spain, Kenya, United Kingdom, United Arab Emirates, Kazakhstan, Egypt, Saudi Arabia, Gambia, Argentina, Romania, Tibet, France, Chile, Gabon, South Africa, Trinidad & Tobago,Tunisia, Turkey, Nigeria, Peru, Russia, Chile, Nigeria, Hungary, Qatar, Greece, Malaysia, Kuwait, Poland, Thailand, Poland.

New York City, Los Angeles, Chicago, Houston, Phoenix, Philadelphia, San Antonio, San Diego, Dallas, San Jose, Austin, Jacksonville, Fort Worth, Columbus, Charlotte, San Francisco, Indianapolis, Seattle, Denver, Washington, Boston, El Paso, Nashville, Detroit, Oklahoma City, Portland, Las Vegas, Memphis, Louisville, Baltimore, Milwaukee, Albuquerque, Tucson, Fresno, Mesa, Sacramento, Atlanta, Kansas City, Colorado Springs, Omaha, Raleigh, Miami, Long Beach, Virginia Beach, Oakland, Minneapolis, Tulsa, Tampa, Arlington, New Orleans, Wichita, Bakersfield, Cleveland, Aurora, Anaheim, Honolulu, Santa Ana, Riverside, Corpus Christi, Lexington, Henderson, Stockton, Saint Paul, Cincinnati, St. Louis, Pittsburgh, Greensboro, Lincoln, Anchorage, Plano, Orlando, Irvine, Newark, Durham, Chula Vista, Toledo, Fort Wayne, St. Petersburg, Laredo, Jersey City, Chandler, Madison, Lubbock, Scottsdale, Reno, Buffalo, Gilbert, Glendale, North Las Vegas, Winston-Salem, Chesapeake, Norfolk, Fremont, Garland, Irving, Hialeah, Richmond, Boise, Spokane, Baton Rouge, Tacoma, San Bernardino, Modesto, Fontana, Des Moines, Moreno Valley, Santa Clarita, Fayetteville, Birmingham, Oxnard, Rochester, Port St. Lucie, Grand Rapids, Huntsville, Salt Lake City, Frisco, Yonkers, Amarillo, Glendale, Huntington Beach, McKinney, Montgomery, Augusta, Aurora, Akron, Little Rock, Tempe, Columbus, Overland Park, Grand Prairie, Tallahassee, Cape Coral, Mobile, Knoxville, Shreveport, Worcester, Ontario, Vancouver, Sioux Falls, Chattanooga, Brownsville, Fort Lauderdale, Providence, Newport News, Rancho Cucamonga, Santa Rosa, Peoria, Oceanside, Elk Grove, Salem, Pembroke Pines, Eugene, Garden Grove, Cary.

Our Products

Our Latest Blogs

Carbon Steel vs Stainless Steel: Key Differences You Need to Know

Picking the right steel for any job in industry is a pretty big deal. Whether you're building huge pipelines, putting up buildings, or making tiny, precise parts, the steel you choose affects how well things work, how long they last, and what they cost. Lots of folks...

What is ERW Pipe and How Are ERW Pipes Made?

When you think about materials that build our world, steel pipes are right up there. They're essential for so many things, from carrying water to supporting buildings. Among the different kinds of steel pipes, ERW pipe – which stands for Electric Resistance Welded...

What is an Alloy? A Complete Guide to Alloy Metal

Ever think about alloys all around you. Strong car wheels for example. Or kitchen tools that don't rust. Yes, alloys are everywhere. But many people do not really know what is an alloy. In this blog, we will discuss everything about alloys. We will talk about what...

Related Products

- Stainless Steel 304 Single Slotted Pipe

- Stainless Steel 304 Double Slotted Pipe

- Stainless steel 304 fittings

- Stainless Steel 304 Components

- Stainless Steel 309 Rod/Bar

- Stainless Steel 309 Hex Bar

- Stainless Steel 309 Square Bar

- Stainless Steel 309 Welded Pipes

- Stainless Steel 309 Plates Sheet

- Stainless steel 309 fittings

- Stainless Steel 309 Components

- Stainless Steel 310 Rod / Bar

- Stainless steel 310 Hex Bars

- Stainless Steel 310 Square Bar

- Stainless Steel 310 Welded Pipes

- Stainless Steel 310 Plates/Sheet

- Stainless Steel 310 Seamless Pipes

- Stainless steel 310 Welded Tubes

- Stainless steel 310 fittings

- Stainless steel 310 channels

- Stainless steel 310 H Beam

- Stainless steel 310 I Beam

- Stainless steel 310 seamless tubes

- Stainless Steel 310 Components

- Stainless Steel 316 / 316Ti Flanges

- Stainless Steel 316 / 316Ti Rod

- Stainless Steel 316 / 316Ti Hex Bars

- Stainless Steel 316 / 316Ti Square Bars

- Stainless Steel 316 / 316Ti Seamless Pipes

- Stainless Steel 316 / 316Ti Welded Pipes

- Stainless Steel 316 / 316Ti Plates

- Stainless Steel 316 / 316Ti Welded Tubes

- Stainless Steel 316 / 316Ti Seamless Tubes

- Stainless Steel 316 / 316Ti Flat Bars

- Stainless Steel 316 / 316Ti Angles

- Stainless Steel 316 / 316Ti Channels

- Stainless Steel 316 / 316Ti H Beams

- Stainless Steel 316 / 316Ti I Beam

- Stainless Steel 316 / 316Ti Pipe Fittings

- Stainless Steel 316 Single Slotted Pipe

- Stainless Steel 316 Double Slotted Pipe

- Stainless Steel 316/316Ti Components

- Stainless Steel 317L Flanges

- Stainless Steel 317L Rod/Bar

- Stainless Steel 317L Hex Bar

- Stainless steel 317L Square Bar

- Stainless Steel 317L Plates/Sheet

- Stainless steel 317L channels

- Stainless steel 317L H Beam

- Stainless steel 317L I Beam

- Stainless steel 317L fittings

- Stainless Steel 317L Components

- Stainless Steel 321 / 347 Flanges

- Stainless Steel 321/347 Rod/Bar

- Stainless Steel 321/347 Hex Bar

- Stainless Steel 321/347 Square Bar

- Stainless Steel 321/347 Seamless Pipes

- Stainless Steel 321/347 Welded Pipes

- Stainless Steel 321 / 347 Pipe Fittings

- Stainless Steel 321/347 Plates/Sheet

- Stainless steel 321 / 347 Welded Tubes

- Stainless steel 321 / 347 seamless tubes

- Stainless steel 321 / 347 channels

- Stainless steel 321 / 347 H Beam

- Stainless steel 321 / 347 I Beam

- Stainless Steel 321 / 347 Components

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 Flange

- Stainless Steel 409/409M/409L/410/430/430F/431/439/441 Rod/Bars

- Stainless Steel 409/409M/409L/410/430/430F/431/439/441 Hex Bar

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 Square Bar

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 Welded Pipes

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 Sheet /Plates/Coil

- Stainless Steel 409/409M/409L/410/430/430F/431/439/441 Welded tubes

- Stainless Steel 409/409M/409L/410/430/430F/431/439/441 Channel

- Stainless Steel 409/409M/409L/410/430/430F/431/439/441 H Beam

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 I Beam

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 Components

- Stainless Steel 420/ 420B & 420C Rod/Bar

- Stainless steel 420 / 420B & 420C hex bars

Send Us Message

Got a question? We'd love to hear from you. Send us a message & we'll respond as soon as possible.