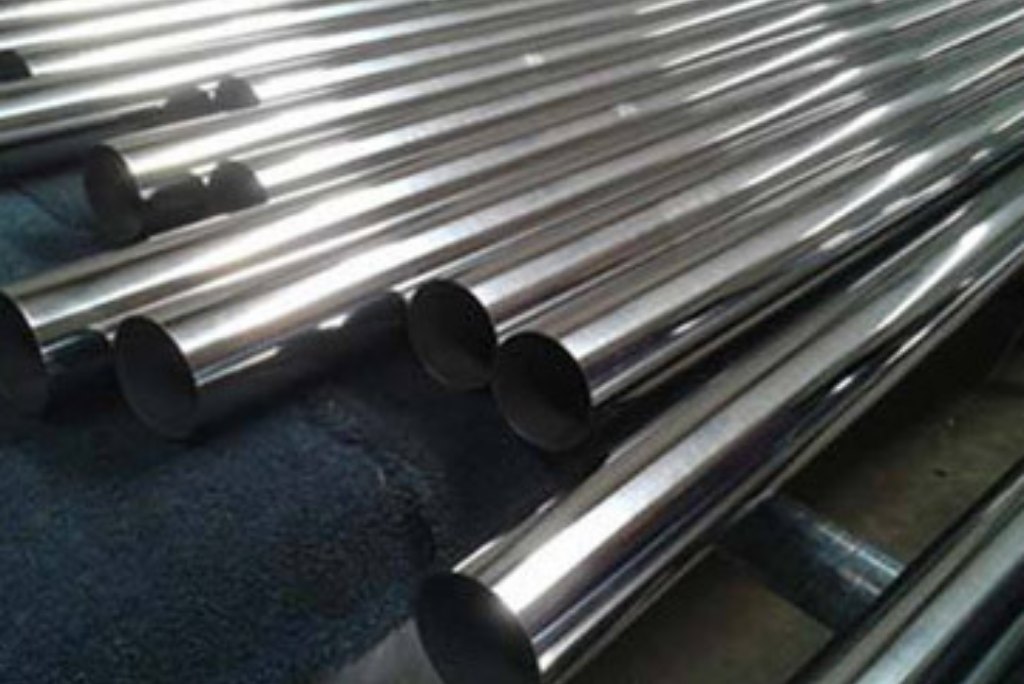

Stainless Steel Tubes, Stainless Steel 202 Tubes, Astm A312 Ss 202 Welded Tubes, Stainless Steel 202 Welded Tubes Suppliers, Seamless Steel Tubing Suppliers, ASTM A554 Stainless Steel Tubing, Stainless Steel 202 Welded Tubes Manufacturer & Exporter in India

What is SS 202 Welded Tube?

Stainless Steel 202 Welded Tube play a crucial role in construction and various industrial projects, finding applications in automotive components, water supply systems, oil refineries, and other energy-related industries. Additionally, these pipes are commonly used for structural framing in commercial buildings due to their exceptional resistance to corrosion.

The welded Stainless Steel 202 tube stands out as the most prevalent type, characterized by its seamless construction, imparting superior strength and durability compared to pipes with welded seams. Welded and Electric Resistance Welding (ERW) pipes are also available to cater to diverse applications based on specific needs.

The primary advantages of employing SS 202 welded tubes include their impressive durability and resistance to corrosion, making them well-suited for deployment in corrosive environments where alternative materials might falter in the face of chemical exposure or moisture. These pipes are not only easy to maintain but also boast a long lifespan, lasting several decades with proper care. Additionally, their excellent thermal insulation properties contribute to energy cost reduction in heating or cooling systems incorporating piping made from this material.

Typically, the standard dimensions for Stainless Steel 202 tube range from 12mm to 500mm in outer diameter (OD), with thickness variations spanning 0.2mm to 8mm. These specifications can be adjusted based on specific customer requirements, including adherence to ASTM A312 standards, which define precise tolerances related to wall thickness measurement accuracy.

In the realm of Stainless Steel 202 Tubes, their applications span across diverse industries such as automotive manufacturing, construction, oil and gas extraction, and petrochemical processing. They serve as structural components in industrial piping and plumbing systems, finding particular relevance in highly corrosive environments like industrial water treatment plants or offshore oil wells.

The standout features of Stainless Steel 202 Welded Tubes lie in their superior strength and durability, surpassing alternative materials like plastic or aluminum. Their inherent corrosion resistance stems from the alloy composition, combining chromium with nickel to form a protective layer against oxidation over time. Moreover, Lakshya International offer flexibility, easily accommodating modifications to suit various environments with minimal effort or expense.

202 Stainless Steel Welded Tube, 202 Stainless Steel welded Tube, 202 Stainless Steel Welded Tube, 202 Stainless Steel welded Pipe, 202 Stainless Steel Welded Tubing, 202 Stainless Steel Welded Tubing, 202 Stainless Steel Instrumentation Tubes Supplier, SS 202 Welded Tube, ASTM A312 TP 202 Stainless Steel Tubes, 202 Stainless Steel Welded Tube, SS 202 Drawn over mandrel (DOM) manufacturer, supplier & distributor in India

Specifications of Stainless Steel 202 Welded Tube:

|

Specifications |

: |

ASTM A/ASME SA213/A249/A269/A312/A358 CL. I to V ASTM A789/A790 |

|---|---|---|

|

Dimensions |

: |

ASTM, ASME and API |

|

202 Pipes & Tubes |

: |

1/2″ NB – 16″ NB |

|

ERW 202 Pipes & Tubes |

: |

1/2″ NB – 24″ NB |

|

EFW 202 Pipes & Tubes |

: |

EFW 202 Tubes |

|

Size |

: |

1/8″NB TO 30″NB IN |

|

Schedule |

: |

SCH5, SCH10, SCH20, SCH30, SCH40, Std, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

|

Type |

: |

Seamless / ERW / Welded / Fabricated / LSAW Pipes |

|

Specialized in |

: |

Large Diameter Size |

|

Length |

: |

Single Random, Double Random & Cut Length. |

|

Form |

: |

Round, Square, Rectangular, Hydraulic Etc |

|

End |

: |

Plain End, Beveled End, Treaded |

202 Stainless Steel Welded Tube Chemical Composition:

|

Grade 202 |

C |

Mn |

Si |

P |

S |

Cr |

Ni |

N |

|

max. |

0.15 |

7.50-10 |

1 |

0.060 |

0.030 |

17- 19 |

4-6 |

0.25 |

Physical properties of SS Tube:

|

Density (g/cm3) |

Elastic Modulus (GPa) |

Poisson’s Ratio |

High Temperature |

|

7.8 |

190-210 |

0.27-0.30 |

800 ℃ |

ASTM A312 / A213 SS 202 Pipes & Tubing Mechanical Properties:

|

Grade |

Tensile Strength (MPa) min |

Yield Strength 0.2% Proof (MPa) min |

Elongation (% in 50mm) min |

|

202 |

515 |

275 |

40 |

Stainless Steel 202 Welded Tube Equivalent Grades:

|

STANDARD |

UNS |

WERKSTOFF NR. |

|

SS 202 |

S20200 |

1.4373 |

Types of Stainless Steel 202 Welded Tube:

|

SS 202 Tube Manufacturer In Mumbai |

SS 202 Rectangular Tubes |

|

SS 202 Tubes |

Stainless Steel 202 Rectangle Tube |

|

Ss 202 Square Tube |

UNS S20200 Square Tube |

|

SS 202 Round Tube |

SS 202 Square Tubes |

|

Stainless Steel 202 Tube |

202 Stainless steel coil Tube |

|

SS 202 Tube |

capillary 202 stainless steel seamless Tube |

|

Schedule 40 Stainless Steel Tube T-202 |

202 Mirror Welded Stainless Steel Tube |

|

Schedule 80 Stainless Steel Tube T-202 |

hot dip galvanized stainless steel 202 Tube |

|

202 Stainless Steel Tube |

202 round square rectangular stainless steel Tube |

|

Stainless Steel 202 Round Tube |

ASTM AISI 202 2B/ BA Seamless Stainless Steel Tube |

|

ASTM A312 TP 202 Stainless Steel Seamless Tube manufacturer |

TP202 / 1.4401 Large Diameter Stainless Steel Tube Seamless |

|

ASTM A312 202 Stainless Steel Tube |

202 stainless steel capillary Tube |

|

202 Stainless Steel Seamless Tube and Tube |

Astm A312 202 Seamless Stainless Structural Steel Tube |

|

Nominal Bore (NB) Schedule 10S 202 Stainless Steel Tube |

SUS 202 Welded Stainless Steel Tube |

|

Stainless Steel Tube -Type 202 Schedule 5S |

3/16″ 202 Stainless Steel Tube |

|

Stainless Steel 202 Seamless Tubes/Welded Tube Supplier |

202 Mirror Welded Stainless Steel Tube |

|

202 Stainless Steel Tube Price |

202 stainless steel capillary Tube |

|

Stainless Steel Tube 202 Manufacturers in Ahmedabad |

Astm A312 202 Seamless Stainless Structural Steel Tube |

|

Stainless Steel 202 Tubes |

hot dip galvanized stainless steel 202 Tube |

|

ASTM A358 TP 202L Stainless Steel EFW Tubes |

polished 202 stainless steel Tube price |

|

SS 202 Grade Stainless Steel Tube Manufacturers in India |

Stainless Steel 202 Tube Cut To Size |

Frequently Asked Questions:

Can stainless steel 202 tubing be welded?

Yes, stainless steel 202 tubing can be welded using a variety of methods, including gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and shielded metal arc welding (SMAW). However, it is important to use the correct welding parameters and procedures to avoid weld defects.

What is stainless steel 202 welded tube used for?

Stainless steel 202 welded tube is used in a variety of applications, including:

- Food processing: Stainless steel 202 welded pipe is often used in food processing equipment because it is resistant to corrosion and easy to clean.

- Chemical processing: Stainless steel 202 welded pipe is also used in chemical processing equipment because it can withstand exposure to a variety of chemicals.

- Marine applications: Stainless steel 202 welded pipe is used in marine applications because it is resistant to saltwater corrosion.

- Automotive applications: Stainless steel 202 welded pipe is sometimes used in automotive exhaust systems because it can withstand high temperatures.

What is a welded 202 steel tube?

A welded 202 steel tube is a type of stainless steel tube that is made by welding two pieces of stainless steel together. Welded 202 steel tubes are typically less expensive than seamless stainless steel tubes, but they are also not as strong.

What are the advantages of SS 202 welded tube?

The advantages of SS 202 welded tube include:

- Cost-effectiveness: SS 202 is a relatively affordable stainless steel grade compared to other options like 304.

- Good corrosion resistance: SS 202 exhibits excellent corrosion resistance in mild environments, making it suitable for various applications.

- High strength and toughness: SS 202 possesses high tensile strength and toughness, allowing it to withstand demanding conditions.

- Weldability: SS 202 is readily weldable using common welding techniques, ensuring easy fabrication.

- Versatility: SS 202 finds applications in diverse industries, including food processing, chemical processing, and construction.

Our Products

Our Latest Blogs

Carbon Steel vs Stainless Steel: Key Differences You Need to Know

Picking the right steel for any job in industry is a pretty big deal. Whether you're building huge pipelines, putting up buildings, or making tiny, precise parts, the steel you choose affects how well things work, how long they last, and what they cost. Lots of folks...

What is ERW Pipe and How Are ERW Pipes Made?

When you think about materials that build our world, steel pipes are right up there. They're essential for so many things, from carrying water to supporting buildings. Among the different kinds of steel pipes, ERW pipe – which stands for Electric Resistance Welded...

What is an Alloy? A Complete Guide to Alloy Metal

Ever think about alloys all around you. Strong car wheels for example. Or kitchen tools that don't rust. Yes, alloys are everywhere. But many people do not really know what is an alloy. In this blog, we will discuss everything about alloys. We will talk about what...

Related Products

- Stainless Steel 304 Single Slotted Pipe

- Stainless Steel 304 Double Slotted Pipe

- Stainless steel 304 fittings

- Stainless Steel 304 Components

- Stainless Steel 309 Rod/Bar

- Stainless Steel 309 Hex Bar

- Stainless Steel 309 Square Bar

- Stainless Steel 309 Welded Pipes

- Stainless Steel 309 Plates Sheet

- Stainless steel 309 fittings

- Stainless Steel 309 Components

- Stainless Steel 310 Rod / Bar

- Stainless steel 310 Hex Bars

- Stainless Steel 310 Square Bar

- Stainless Steel 310 Welded Pipes

- Stainless Steel 310 Plates/Sheet

- Stainless Steel 310 Seamless Pipes

- Stainless steel 310 Welded Tubes

- Stainless steel 310 fittings

- Stainless steel 310 channels

- Stainless steel 310 H Beam

- Stainless steel 310 I Beam

- Stainless steel 310 seamless tubes

- Stainless Steel 310 Components

- Stainless Steel 316 / 316Ti Flanges

- Stainless Steel 316 / 316Ti Rod

- Stainless Steel 316 / 316Ti Hex Bars

- Stainless Steel 316 / 316Ti Square Bars

- Stainless Steel 316 / 316Ti Seamless Pipes

- Stainless Steel 316 / 316Ti Welded Pipes

- Stainless Steel 316 / 316Ti Plates

- Stainless Steel 316 / 316Ti Welded Tubes

- Stainless Steel 316 / 316Ti Seamless Tubes

- Stainless Steel 316 / 316Ti Flat Bars

- Stainless Steel 316 / 316Ti Angles

- Stainless Steel 316 / 316Ti Channels

- Stainless Steel 316 / 316Ti H Beams

- Stainless Steel 316 / 316Ti I Beam

- Stainless Steel 316 / 316Ti Pipe Fittings

- Stainless Steel 316 Single Slotted Pipe

- Stainless Steel 316 Double Slotted Pipe

- Stainless Steel 316/316Ti Components

- Stainless Steel 317L Flanges

- Stainless Steel 317L Rod/Bar

- Stainless Steel 317L Hex Bar

- Stainless steel 317L Square Bar

- Stainless Steel 317L Plates/Sheet

- Stainless steel 317L channels

- Stainless steel 317L H Beam

- Stainless steel 317L I Beam

- Stainless steel 317L fittings

- Stainless Steel 317L Components

- Stainless Steel 321 / 347 Flanges

- Stainless Steel 321/347 Rod/Bar

- Stainless Steel 321/347 Hex Bar

- Stainless Steel 321/347 Square Bar

- Stainless Steel 321/347 Seamless Pipes

- Stainless Steel 321/347 Welded Pipes

- Stainless Steel 321 / 347 Pipe Fittings

- Stainless Steel 321/347 Plates/Sheet

- Stainless steel 321 / 347 Welded Tubes

- Stainless steel 321 / 347 seamless tubes

- Stainless steel 321 / 347 channels

- Stainless steel 321 / 347 H Beam

- Stainless steel 321 / 347 I Beam

- Stainless Steel 321 / 347 Components

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 Flange

- Stainless Steel 409/409M/409L/410/430/430F/431/439/441 Rod/Bars

- Stainless Steel 409/409M/409L/410/430/430F/431/439/441 Hex Bar

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 Square Bar

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 Welded Pipes

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 Sheet /Plates/Coil

- Stainless Steel 409/409M/409L/410/430/430F/431/439/441 Welded tubes

- Stainless Steel 409/409M/409L/410/430/430F/431/439/441 Channel

- Stainless Steel 409/409M/409L/410/430/430F/431/439/441 H Beam

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 I Beam

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 Components

- Stainless Steel 420/ 420B & 420C Rod/Bar

- Stainless steel 420 / 420B & 420C hex bars

Send Us Message

Got a question? We'd love to hear from you. Send us a message & we'll respond as soon as possible.