Nickel 200 & 201 Flanges Manufacturer and Supplier in India

Lakshay Steel is a partner you can trust for the top quality Nickel Alloy Flanges you need in Nickel 200 or Nickel 201. As a leading Manufacturer, Supplier and Exporter we make flanges that will last in the toughest applications. Specifically, it is designed to effectively resist corrosion, survive extreme heat, and long lasting durability and shelf life. Therefore, the flanges are in use in chemical plants, marine applications, and many industrial applications. When reliability in flanges is needed, Lakshay Steel has you covered.

What Is Nickel 200 Flanges?

What is Nickel 201 Flange?

Because Nickel 201 has less carbon, it’s better for jobs where things can get hotter than 600ºF (that’s about 315°C). It doesn’t change its structure (graphitization) as easily as Nickel 200 at those high temps. So, you’ll find Nickel 201 Flanges in high-temperature applications such as combustion boats, caustic evaporators, plater bars, and electronic components.

at Lakshay Steel, we really care about giving you great quality at competitive prices for our Nickel 200 and 201 flanges. You can trust us to give you top-notch products and make sure you’re happy with what you get. For all your Nickel Alloy 200 and 201 flange needs, we’re the ones to call!

Nickel 200 and 201 Flanges Specification :

Our flanges are manufactured in compliance with:

| Property | Details |

| Product Name | Nickel 200 Flanges |

| Monel Specification | ASTM / ASME B564, BS, DIN |

| Monel UNS Grade | Nickel 200 – Nickel Alloy 200 (UNS No. N02200), 2.4066, 2.4068 Nickel 201 – Nickel Alloy 201 (UNS No. N02201), 2.4068, 2.4066 |

| Monel Flange Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Size | ½″ NB to 60″ NB |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Monel Flange Class / Pressure | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, ASA 150#, ASA 300#, DIN 6 to 160, JIS 5K to 40K, etc. |

Nickel 200 and 201 Flanges Chemical Composition

| Grade | Ni | Fe | Cu | C | Mn | S | Si |

| 200 | 99.0 min | 0.40 | 0.25 | 0.15 | 0.35 | 0.01 | 0.35 |

| 201 | 99.0 min | 0.40 | 0.25 | 0.02 | 0.35 | 0.01 | 0.35 |

Nickel 200 and 201 Flanges Mechanical Properties

| Grade | Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 200-201 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 21500 , MPa – 148 | Psi – 67000 , MPa – 462 | 45 % |

Nickel 200 and 201 Pipe Flanges Equivalent Grades

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS | GOST |

| Nickel 200 | N02200 | 2.4066 | N-100M | Ni 99.2 | NW 2200 | NA 11 | НП-2 |

| Nickel 201 | N02201 | 2.4068 | – | LC-Ni 99 | NW 2201 | NA 11 | НП-2 |

Application of Nickel Alloy 200 / 201 Flanges

Honestly, you’ll find our ASTM B564 200/201 Nickel Alloy Flanges being used in tons of different industries, like:

- Oil and Gas Pipelines: They’re tough enough for the demanding conditions there.

- Chemical Industry: Perfect for handling all sorts of corrosive stuff.

- Plumbing: Even in everyday plumbing, you need reliable connections.

- Heating: They can definitely take the heat!

- Water Supply Systems: Ensuring clean and reliable water flow.

- Power Plants: Handling high pressures and temperatures.

- Paper & Pulp Industry: Standing up to the harsh chemicals used.

- General Purpose Applications: Just good, solid, dependable flanges for all sorts of things.

- Fabrication Industry: Helping to build and put together all kinds of structures.

- Food Processing Industry: Made with materials you can trust for hygiene.

- Structural Pipe: Providing strong connections for building frameworks.

Types of Nickel Flanges

Explore our extensive inventory of Nickel 200 and 201 flanges, including:

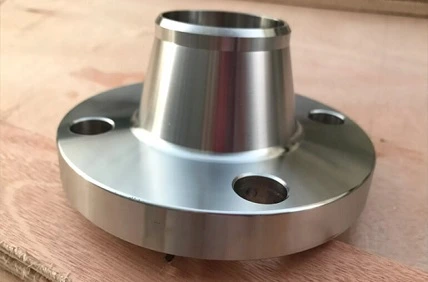

Weld Neck Flanges

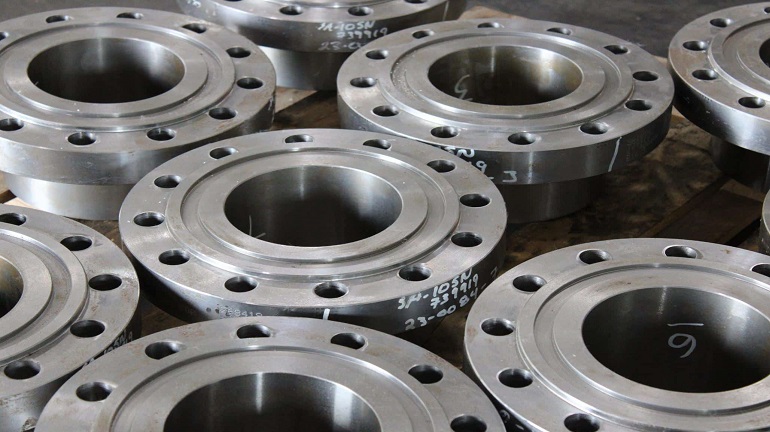

Slip-On Flanges

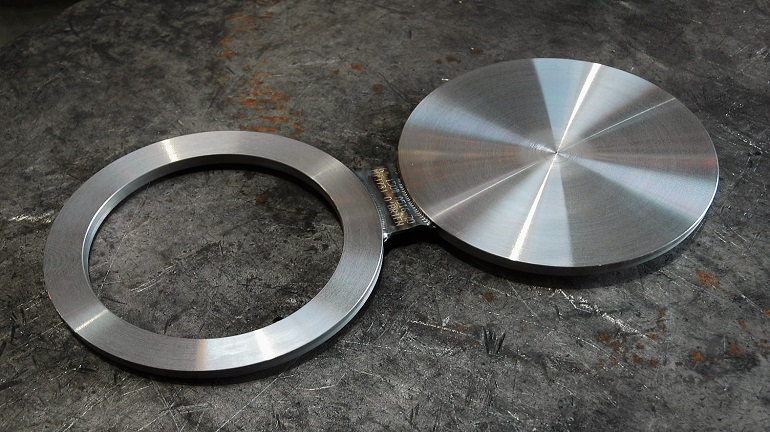

Blind Flanges

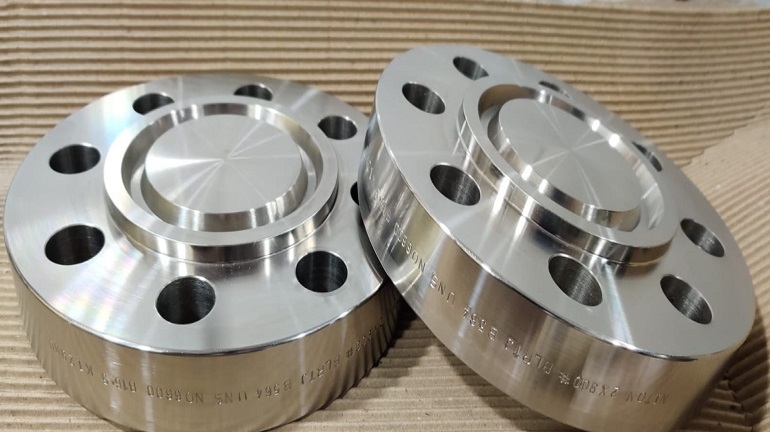

Socket Weld Flanges

Threaded Flanges

Custom Forged Flanges

Available Nickel 200 Flanges

CONTACT US TO GET A QUOTE FOR YOUR REQUIREMENTS

We deliver high-quality materials on time, ensuring reliable, cost-effective solutions that meet all industry standards

FAQs for Nickel Alloy 200 / 201 Flanges:

What is Nickel 200?

Nickel 200 is a commercially pure wrought nickel with excellent mechanical properties and corrosion resistance. It is often used in chemical processing, aerospace, and food processing applications.

What is the difference between Nickel 200 and Nickel 201?

Nickel 200 and 201 differ primarily in carbon content. Nickel 201, the low-carbon version of Nickel 200, contains a maximum of 0.02% carbon compared to 200’s 0.15% maximum. This difference in carbon levels leads to their use in slightly different applications.

What is equivalent to Nickel 201?

Nickel 201 equivalents include ASME SB-160/-163, SAE AMS 5553, DIN 17740/17750-17754, BS 3072-3076, and ASTM B 160/-163/725/730. Always verify specific requirements within the relevant standard.

What is nickel 200 used for?

Nickel 200’s corrosion resistance makes it ideal for maintaining purity in food, synthetic fiber, and caustic alkali handling, and is also valuable in corrosion-resistant structural applications.

Our Products

Our Latest Blogs

Complete Guide to 304 Stainless Steel Tubes (304 SS Tubes)

Introduction to 304 Stainless Steel Tubes Industrial piping and construction is an industry that...

Hastelloy C276 Round Bars: Complete Guide

Hastelloy C276 is a superalloy that is known to be very versatile and possess remarkable high...

SAE 8620 Alloy Steel: Chemical Composition, Heat Treatment & Applications

SAE AISI 8620 steel is a widely used alloy that is prized for its combination of strength,...

Related Products

Send Us Message

Got a question? We'd love to hear from you. Send us a message & we'll respond as soon as possible.