Hastelloy c22 Round Bars

Table of Content

- Highly Recommended Manufacturer and Supplier of Hastelloy C22 Round Bars

- What are the uses of UNS N06022 material Hastelloy Round Bars?

- Hastelloy c22 Round Bar Specification

- Chemical Composition of Hastelloy c22 Round Bar

- Mechanical Properties for Hastelloy c22 Round Bar

- Hastelloy c22 Round Bar Equivalent Grades

- Hastelloy c22 Round Bar Weight Chart

- Hastelloy c22 Round Bar Size Chart

- Hastelloy c22 Round Bar Types

- Hastelloy c22 Round Bar Applications

Information

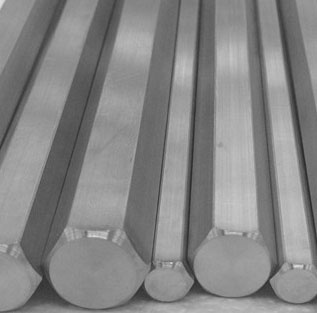

Hastelloy C22 Forged Bar, Hastelloy Alloy C22 Square Bar, Hastelloy Alloy C22 Bright Bar, Hastelloy Alloy C22 Hex Bar Supplier in India, Alloy C22 Round Bar Stockists in Mumbai, Hastelloy C22 Flat Bar, Hastelloy C22 Grade Square Bar, C22 Hastelloy Polished Round Bar, Hastelloy Alloy C22 Round Bar Manufacturer in India, Hastelloy UNS N06022 Round Bars, ASTM B574 Hastelloy C22 Bright Bar, ASTM B574 Hastelloy Alloy C22 Cold Rolled Round Bars, Alloy C22 Square Bars Exporters.

Hastelloy C22 Round Bar

Hastelloy C22 Hex Bar

Hastelloy C22 Square Bar

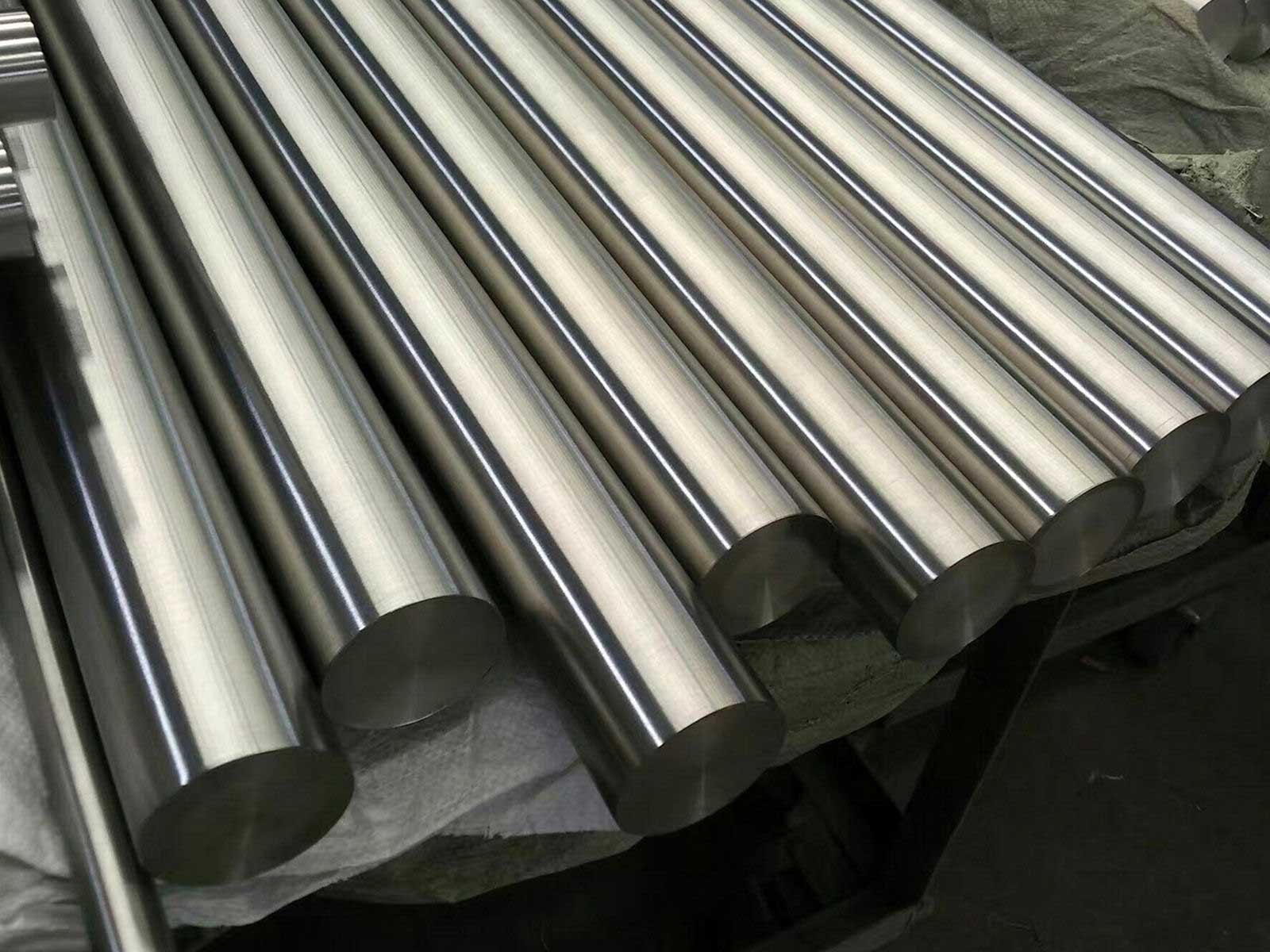

Highly Recommended Manufacturer and Supplier of Hastelloy C22 Round Bars

Lakshya Steel is a trusted manufacturer and supplier of Hastelloy C22 Round Bars, providing a wide range of high-quality products both national and international. Our Hastelloy products and Hastelloy C22 Bars, known for their excellent resistance to oxidizing environments such as wet chlorine and mixtures with nitric acid and chloride ions, are ideal for various demanding applications. These Hastelloy C22 Round Bars also referred to as Alloy C22 (UNS N06022), offer exceptional performance due to their ability to withstand corrosion from a broad range of chemicals, including chlorides and organic solutions. They can be easily cold-worked due to their high ductility, making cold-forming a preferred method for shaping them. The bars can be annealed at temperatures between 2020°F and 2150°F, followed by rapid quenching, to enhance their properties. Hastelloy C22 is renowned for its versatile performance, exhibiting excellent resistance to both crevice and pitting corrosion, as well as stress corrosion cracking. This makes it an excellent choice for applications in flue gas desulfurization plants and other chemical processing industries where conditions may vary or be challenging. The alloy’s low carbon content enhances its weldability, ensuring high-quality welds and resistance to intergranular corrosion in the heat-affected zone.

At Lakshya Steel, we ensure our Hastelloy C22 Round Bars meet international quality standards and offer custom sizes to fit our client’s specific needs. Our products are designed to provide outstanding performance and security, making them a top choice for industries requiring high resistance to harsh environments.

If you have any questions about our products, contact us now for your requirements.

What are the uses of UNS N06022 material Hastelloy Round Bars?

UNS N06022 Hastelloy round bars are highly valued by manufacturers for their outstanding strength, temperature resistance, and corrosion resistance. These materials are extensively used in chemical processing, where they form critical tubing components for handling caustic liquids. Their strength and versatility also make them ideal for power generation piping, petrochemical reactors, and heat exchangers. In marine applications, Hastelloy round bars are used for constructing exhaust rings, propellers, and connecting pipes due to their non-magnetic properties and exceptional longevity. Their above metallurgical construction ensures toughness and security even in high-temperature environments, making them a preferred choice for demanding industrial applications.

Hastelloy c22 Round Bar Specification

| Dimensions | DIN, EN, ASTM, JIS, ASME, BS, AISI |

|---|---|

| Round bar size | Diameter: 3-~800mm |

| Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Rectangular Bars Section | 3.0 to 12.0mm thickness |

| Billet Size | 1/2 to 495mm Diameter |

| Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Dimensions | Diameter / Height: |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Surface | Hot Rolled Pickled, Bright, Sand Blasting Finished, Cold Drawn, Hairline,Polished |

| Condition | Hardened & tempered, annealed |

| Technique | Stainless Steel Cold Drawn, Hot Rolled, Forged Round Bar,Cold Rolled, Rod |

| Processing | Bar cutting to 650mm |

| Form | Rod, Round, Channel Bar, T-Bar, Flat Bar, Precision Ground Bar, Blocks, Square, Rings, Round Rod, Triangle, Hollow, Rectangle, Threaded, Hex (A/F), Profiles, Half Round Bar, Ingot, Billet, I/H Bar, Forging etc. |

Chemical Composition of Hastelloy c22 Round Bar

| Grade | Ni | C | Cr | Co | Fe | Mn | Mo | P | Si | S | W | V |

| Hastelloy C22 | Bal | 0.010 max | 20 – 22.5 | 2.5 max | 2 – 6 | 0.50 max | 12.5 – 14.5 | 0.02 max | 0.08 max | 0.02 max | 2.5 – 3.5 | 0.35 max |

Mechanical Properties for Hastelloy c22 Round Bar

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.69 g/cm3 | 1399 °C (2550 °F) | Psi – 1,00,000 , MPa – 690 | Psi – 45000 , MPa – 310 | 45 % |

Hastelloy c22 Round Bar Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | GOST | AFNOR | JIS | OR | EN |

| Hastelloy C22 | 2.4602 | N06022 | – | – | NW 6022 | – | NiCr21Mo14W |

Hastelloy c22 Round Bar Weight Chart

| Round Bar | ||||||||

| Size | Kgs / Foot | Kgs / Mtr | Size | Kgs / Foot | Kgs / Mtr | Size | Kgs / Foot | Kgs / Mtr |

| 3mm | 0.017 | 0.055 | 20mm | 0.753 | 2.470 | 3″ | 10.900 | 35.762 |

|---|---|---|---|---|---|---|---|---|

| 1/8″ | 0.019 | 0.062 | 22mm | 0.908 | 2.979 | 3-1/4″ | 12.800 | 41.996 |

| 5/32″ | 0.029 | 0.095 | 7/8″ | 0.926 | 3.038 | 3-1/2″ | 14.850 | 48.772 |

| 4mm | 0.030 | 0.098 | 24mm | 1.080 | 3.543 | 3-3/4″ | 17.001 | 55.780 |

| 3/16″ | 0.043 | 0.141 | 25mm | 1.180 | 3.871 | 4″ | 19.306 | 63.340 |

| 5mm | 0.047 | 0.154 | 1″ | 1.210 | 3.970 | 4-1/4″ | 21.908 | 72.249 |

| 7/32″ | 0.058 | 0.190 | 26mm | 1.271 | 4.170 | 4-1/2″ | 24.4487 | 80.340 |

| 6mm | 0.068 | 0.223 | 27mm | 1.368 | 4.490 | 4-3/4″ | 27.366 | 90.249 |

| 1/4″ | 0.076 | 0.249 | 1-1/8″ | 1.534 | 5.033 | 5″ | 30.461 | 99.940 |

| 7mm | 0.091 | 0.298 | 30mm | 1.691 | 5.548 | 5-1/2″ | 36.690 | 121.000 |

| 5/16″ | 0.118 | 0.387 | 1-1/4″ | 1.924 | 6.349 | 6″ | 43.860 | 143.900 |

| 8mm | 0.120 | 0.398 | 32mm | 1.894 | 6.314 | 6-1/2″ | 51.093 | 167.630 |

| 9mm | 0.152 | 0.498 | 1-3/8″ | 2.303 | 7.550 | 7″ | 59.432 | 196.000 |

| 3/8″ | 0.170 | 0.557 | 35mm | 2.390 | 7.553 | 7-1/2″ | 68.226 | 225.000 |

| 10mm | 0.189 | 0.620 | 36mm | 2.438 | 7.999 | 8″ | 77.586 | 254.55 |

| 11mm | 0.228 | 0.748 | 38mm | 2.792 | 8.903 | 10″ | 121.048 | 397.140 |

| 7/16″ | 0.232 | 0.761 | 1-1/2″ | 2.715 | 8.951 | |||

| 12mm | 0.271 | 0.889 | 40mm | 3.009 | 9.872 | |||

| 1/2″ | 0.303 | 0.994 | 1-5/8″ | 3.200 | 10.449 | |||

| 13mm | 0.318 | 1.043 | 1-3/4″ | 3.712 | 12.179 | |||

| 14mm | 0.368 | 1.207 | 45mm | 3.807 | 12.555 | |||

| 9/16″ | 0.383 | 1.256 | 1-7/8″ | 4.260 | 13.977 | |||

| 15mm | 0.424 | 1.391 | 48mm | 4.330 | 14.205 | |||

| 5/8″ | 0.473 | 1.551 | 50mm | 4.698 | 15.414 | |||

| 16mm | 0.481 | 1.578 | 2″ | 4.848 | 15.906 | |||

| 17mm | 0.543 | 1.791 | 2-1/8″ | 5.475 | 17.963 | |||

| 11/16″ | 0.573 | 1.880 | 2-1/4″ | 6.135 | 20.128 | |||

| 18mm | 0.610 | 2.001 | 60mm | 6.768 | 22.205 | |||

| 3/4″ | 0.682 | 2.237 | 2-3/8″ | 6.838 | 22.435 | |||

| 2-1/2″ | 7.576 | 24.856 | ||||||

| 2-5/8″ | 8.354 | 27.409 | ||||||

| 2-3/4″ | 9.169 | 30.083 | ||||||

Hastelloy c22 Round Bar Size Chart

| Metric | US Bar | ASTM/ Canadian | Japanese | ||||

|---|---|---|---|---|---|---|---|

| Bar Size | Diam. (mm) | Bar Size | Diam. (Inch) | Bar Size | Diam. (mm2) | Bar Size | Diam. (mm) |

| 5 | 5 | #2 | 0.250 | 10M | 100 | 6 | 6 |

| 5.5 | 5.5 | #3 | 0.375 | 15M | 200 | 10 | 10 |

| 6 | 6 | #4 | 0.500 | 20M | 300 | 13 | 13 |

| 7 | 7 | #5 | 0.625 | 25M | 500 | 16 | 16 |

| 8 | 8 | #6 | 0.750 | 30M | 700 | 19 | 19 |

| 9 | 9 | #7 | 0.875 | 35M | 1000 | 22 | 22 |

| 10 | 10 | #8 | 1.000 | 45M | 1500 | 25 | 25 |

| 11 | 11 | #9 | 1.125 | 55M | 2500 | 29 | 29 |

| 12 | 12 | #10 | 1.250 | 32 | 32 | ||

| 14 | 14 | #11 | 1.375 | 35 | 35 | ||

| 16 | 16 | #12 | 1.500 | 38 | 38 | ||

| 18 | 18 | #13 | 1.625 | 41 | 41 | ||

| 20 | 20 | #14 | 1.750 | 44 | 44 | ||

| 22 | 22 | #15 | 1.875 | 48 | 48 | ||

| 25 | 25 | #16 | 2.000 | 51 | 51 | ||

| 28 | 28 | #18 | 2.250 | 57 | 57 | ||

| 32 | 32 | ||||||

| 36 | 36 | ||||||

| 40 | 40 | ||||||

| 44 | 44 | ||||||

| 50 | 50 | ||||||

Hastelloy c22 Round Bar Types

Hastelloy UNS N06022 Round Bar

Alloy C22 Hex Bar

Hastelloy Alloy C22 Rod

Hastelloy C22 Bar Material

C22 Hastelloy Flat Bar

WERKSTOFF NR. 2.4602 Square Bar

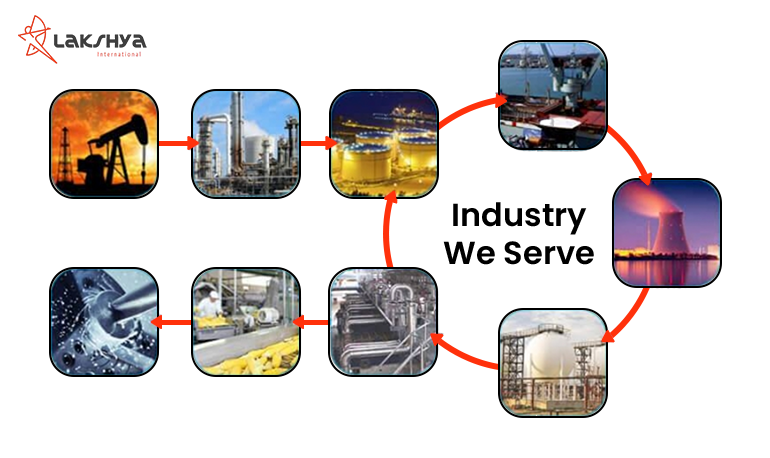

Hastelloy c22 Round Bar Applications

- Construction

- Bridges

- Petrochemical Industry

- Ship Building

- Engineering

- General Structural Purposes

- Offshore and Onshore Services

Our Products

Our Latest Blogs

Carbon Steel vs Stainless Steel: Key Differences You Need to Know

Picking the right steel for any job in industry is a pretty big deal. Whether you're building huge pipelines, putting up buildings, or making tiny, precise parts, the steel you choose affects how well things work, how long they last, and what they cost. Lots of folks...

What is ERW Pipe and How Are ERW Pipes Made?

When you think about materials that build our world, steel pipes are right up there. They're essential for so many things, from carrying water to supporting buildings. Among the different kinds of steel pipes, ERW pipe – which stands for Electric Resistance Welded...

What is an Alloy? A Complete Guide to Alloy Metal

Ever think about alloys all around you. Strong car wheels for example. Or kitchen tools that don't rust. Yes, alloys are everywhere. But many people do not really know what is an alloy. In this blog, we will discuss everything about alloys. We will talk about what...

Related Products

Send Us Message

Got a question? We'd love to hear from you. Send us a message & we'll respond as soon as possible.