Duplex Steel S31803 Hex Bars / Super Duplex S32750 & S32760 Hex Bars

Table of Content

- Duplex UNS S31803 & Super Duplex S32750 / S32760 Hex Bars Specification:

- Duplex UNS S31803 & Super Duplex S32750 / S32760 Hex Bars Chemical Composition

- Duplex UNS S31803 & Super Duplex S32750 / S32760 Hex Bars Mechanical properties

- Duplex UNS S31803 & Super Duplex S32750 / S32760 Hex Bars Equivalent Grades

- Sizes and Weight of Duplex UNS S31803 & Super Duplex S32750 / S32760 Hex Bars

- Duplex UNS S31803 & Super Duplex S32750 / S32760 Hex Bars Available Types

Information

Duplex Steel UNS S31803 Bright Bars, Duplex DIN 1.4462 Bars, UNS S31803 Forged Bars, Duplex Steel UNS S31803 Cold Finished, Annealed available in diversity of sizes in Big stock in small or large quantity, ASTM A276 Duplex Steel UNS S31803 Round Bar, UNS S31803 Black Bars, Duplex Steel UNS S31803 Hex Bars Suppliers in India.

Duplex Steel UNS S31803, S32550, S32750, S32205, S32760 Bars, Rods, Super Duplex Steel UNS S32760, S32750, S32950 Hex Bar Suppliers & Exporters in India.

Detailed Information

Lakshya International is involved in manufacturing and shipping the Duplex UNS S31803 & Super Duplex S32750 / S32760 Hex Bars of good specification. Duplex UNS S31803 & Super Duplex S32750 / S32760 Hex Bars we manufacture are robust to different corrosive media applications. Lakshya International manufactures the Duplex UNS S31803 & Super Duplex S32750 / S32760 Hex Bars using state-of-the-art manufacturing and state-of-the-art equipment in our state-of-the-art production facility. We are utilizing the highest quality of the available raw materials and manufacturing the Duplex UNS S31803 & Super Duplex S32750 / S32760 Hex Bars which are on an equal basis with both international and national quality requirements. Lakshya International has established an industry reputation for the consistency of the goods we deliver. We also take custom orders from our customers at Lakshya International and produce the Duplex UNS S31803 & Super Duplex S32750 / S32760 Hex Bars which meet our customers ‘ expectations and requirements.

Alloy SAF 2507 is a super duplex stainless steel consisting of 25% chromium, 4% molybdenum and 7% nickel. It has been specially developed for use in situations requiring exceptional strength and corrosion resistance, including seawater equipment, chemical and petrochemical processing. This type of stainless steel is also very resistant to chloride stress corrosion cracking, has high thermal conductivity, and has a low coefficient of thermal expansion. Although the 2507 stainless steel alloy is corrosion resistant and known for its strength in many circumstances, it is not recommended for applications requiring long exposure to temperatures around 570 degrees F as this can reduce the durability level. The use of Duplex 2507 should be restricted to applications below 600 ° F (316 ° C). Prolonged exposure to elevated temperature can reduce both the strength and the corrosion resistance of Alloy 2507. Duplex 2507 has excellent mechanical properties. Oftentimes, the lightweight 2507 material can be used to achieve the same design strength as a thicker nickel alloy. The resulting weight savings can dramatically lower the total cost of production.

Stainless Steel Hexagon 2205 Duplex Bar offers plenty of unique benefits for numerous industries and applications. Hexagon bar is also known as hex bar, common uses include nuts, bolts, and repetition turned parts due to its excellent machining characteristics. It has excellent corrosion resistance, good workability and good machinability. Stainless steel hex bar is made from one of the most widely used heat treatable stainless steel alloys in the industry. We have a range of hexagon bar sizes available in stock for quick delivery, alternatively, we can offer cut to length hex bars to meet your needs.

CITIES WE DELIVERED

New York City, Los Angeles, Chicago, Houston, Phoenix, Philadelphia, San Antonio, San Diego, Dallas, San Jose, Austin, Jacksonville, Fort Worth, Columbus, Charlotte, San Francisco, Indianapolis, Seattle, Denver, Washington, Boston, El Paso, Nashville, Detroit, Oklahoma City, Portland, Las Vegas, Memphis, Louisville, Baltimore, Milwaukee, Albuquerque, Tucson, Fresno, Mesa, Sacramento, Atlanta, Kansas City, Colorado Springs, Omaha, Raleigh, Miami, Long Beach, Virginia Beach, Oakland, Minneapolis, Tulsa, Tampa, Arlington, New Orleans, Wichita, Bakersfield, Cleveland, Aurora, Anaheim, Honolulu, Santa Ana, Riverside, Corpus Christi, Lexington, Henderson, Stockton, Saint Paul, Cincinnati, St. Louis, Pittsburgh, Greensboro, Lincoln, Anchorage, Plano, Orlando, Irvine, Newark, Durham, Chula Vista, Toledo, Fort Wayne, St. Petersburg, Laredo, Jersey City, Chandler, Madison, Lubbock, Scottsdale, Reno, Buffalo, Gilbert, Glendale, North Las Vegas, Winston-Salem, Chesapeake, Norfolk, Fremont, Garland, Irving, Hialeah, Richmond, Boise, Spokane, Baton Rouge, Tacoma, San Bernardino, Modesto, Fontana, Des Moines, Moreno Valley, Santa Clarita, Fayetteville, Birmingham, Oxnard, Rochester, Port St. Lucie, Grand Rapids, Huntsville, Salt Lake City, Frisco, Yonkers, Amarillo, Glendale, Huntington Beach, McKinney, Montgomery, Augusta, Aurora, Akron, Little Rock, Tempe, Columbus, Overland Park, Grand Prairie, Tallahassee, Cape Coral, Mobile, Knoxville, Shreveport, Worcester, Ontario, Vancouver, Sioux Falls, Chattanooga, Brownsville, Fort Lauderdale, Providence, Newport News, Rancho Cucamonga, Santa Rosa, Peoria, Oceanside, Elk Grove, Salem, Pembroke Pines, Eugene, Garden Grove, Cary, Fort Collins, Corona, Springfield, Jackson, Alexandria, Hayward, Clarksville, Lakewood, Lancaster, Salinas, Palmdale, Hollywood, Springfield, Macon, Kansas City, Sunnyvale, Pomona, Killeen, Escondido, Pasadena, Naperville, Bellevue, Joliet, Murfreesboro, Midland, Rockford, Paterson, Savannah, Bridgeport, Torrance, McAllen, Syracuse, Surprise, Denton, Roseville, Thornton, Miramar, Pasadena, Mesquite, Olathe, Dayton, Carrollton, Waco, Orange, Fullerton, Charleston, West Valley City, Visalia, Hampton, Gainesville, Warren, Coral Springs, Cedar Rapids, Round Rock, Sterling Heights, Kent, Columbia, Santa Clara, New Haven, Stamford, Concord, Elizabeth, Athens, Thousand Oaks, Lafayette, Simi Valley, Topeka, Norman, Fargo, Wilmington, Abilene, Odessa, Columbia, Pearland, Victorville, Hartford, Vallejo, Allentown, Berkeley, Richardson, Arvada, Ann Arbor, Rochester, Cambridge, Sugar Land, Lansing, Evansville, College Station, Fairfield, Clearwater, Beaumont, Independence, Provo, West Jordan, Murrieta, Palm Bay, El Monte, Carlsbad, North Charleston, Temecula, Clovis, Springfield, Meridian, Westminster, Costa Mesa, High Point, Manchester, Pueblo, Lakeland, Pompano Beach, West Palm Beach, Antioch, Everett, Downey, Lowell, Centennial, Elgin, Richmond, Peoria, Broken Arrow, Miami Gardens, Billings, Jurupa Valley, Sandy Springs, Gresham, Lewisville, Hillsboro, Ventura, Greeley, Inglewood, Waterbury, League City, Santa Maria, Tyler, Davie, Lakewood, Daly City, Boulder, Allen, West Covina, Sparks, Wichita Falls, Green Bay, San Mateo, Norwalk, Rialto, Las Cruces, Chico, El Cajon, Burbank, South Bend, Renton, Vista, Davenport, Edinburg, Tuscaloosa, Carmel, Spokane Valley, San Angelo, Vacaville, Clinton, Bend, Woodbridge.

Duplex UNS S31803 & Super Duplex S32750 / S32760 Hex Bars Specification :

Specification: EN, DIN, JIS, ASTM, BS, ASME, AISI

Standard Specification : ASTM A182, ASTM A276, ASTM A479

Duplex Steel UNS S31803 Round Bar : 6 mm to 120 mm.

Duplex Steel UNS S31803 Square Bars: 10 mm to 200 mm.

Diameter : 6mm to 350mm Diameter

Thickness: 100 to 6000 mm Length

Tolerance : +/-0.2mm

Finish: Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish

Length: Random length 3-6m or fixed length or as per request.

Form: Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc.

Round Bar Type: Hot-forging, Hot Rolled, Cold Drawn, Bright Finish and Black Finsh Round Bar

Condition: 25.4mm and less generally drawn, above 25.4mm and less than 101.6mm is generally annealed, turned and polished. Sizes above 101.6mm are generally rough turned to k12 tolerance.

Chemical Composition for Duplex UNS S31803 & Super Duplex S32750 / S32760 Hex Bars :

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| S31803 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 22.0 – 23.0 | 3.0 – 3.5 | 4.50 – 6.50 | 0.14 – 0.20 | 63.72 min |

| S32750 | 0.030 max | 1.20 max | 0.80 max | 0.035 max | 0.020 max | 24.00 – 26.00 | 3.00 – 5.00 | 6.00 – 8.00 | 0.24 – 0.32 | 58.095 min |

| S32760 | 0.05 max | 1.00 max | 1.00 max | 0.030 max | 0.010 max | 24.00 – 26.00 | 3.00 – 4.00 | 6.00 – 8.00 | 0.20 – 0.30 | 57.61 min |

Mechanical properties for Duplex UNS S31803 & Super Duplex S32750 / S32760 Hex Bars :

|

Grades |

Density (g/cm 3) |

Density (lb/in 3) |

Melting Point (°C) |

Melting Point (°F) |

|

S31803 / S32205 |

7.805 |

0.285 |

1420 – 1465 |

2588 – 2669 |

|

S32750 / S32760 |

7.8 |

0.281 |

1350 |

2460 |

Equivalent Grades for Duplex UNS S31803 & Super Duplex S32750 / S32760 Hex Bars :

|

STANDARD |

WERKSTOFF NR. |

UNS |

|

Duplex 2205 |

1.4462 |

S31803 / S32205 |

|

Super Duplex 2507 |

1.4410 |

S32750 / S32760 |

Sizes and Weight of Duplex UNS S31803 & Super Duplex S32750 / S32760 Hex Bars :

|

HEXAGONS |

||

|

Size(mm) |

WT PER FEET IN KGS |

WT PER MTR IN KGS |

|

16 |

0.55 |

1.79 |

|

18 |

0.69 |

2.27 |

|

20 |

0.85 |

2.80 |

|

22 |

1.03 |

3.39 |

|

25 |

1.33 |

4.38 |

|

28 |

1.67 |

5.49 |

|

30 |

1.92 |

6.30 |

|

32 |

2.19 |

7.17 |

|

36 |

2.77 |

9.07 |

|

38 |

3.08 |

10.11 |

|

40 |

3.41 |

11.20 |

|

45 |

4.32 |

14.18 |

|

50 |

5.34 |

17.50 |

|

56 |

– |

– |

|

60 |

– |

– |

|

65 |

– |

– |

|

70 |

– |

– |

|

75 |

– |

– |

|

80 |

– |

– |

|

90 |

– |

– |

|

100 |

– |

– |

Types of Duplex UNS S31803 & Super Duplex S32750 / S32760 Hex Bars :

- ASME SA276 Duplex Steel UNS S31803 Square Bar, UNS S31803 Bars,

- ASTM A479 Grade F51 UNS S31803 Duplex Steel hot finished hexagon Rods,

- ASME SA479 cold finished Duplex UNS S31803 Hex Bars,

- uper Duplex Steel S32750 Billets

- Ferritic Stainless Steel S32760 Billet Rods

- Super Duplex Steel S32750 Hex

- SAF 2507 Billets & Hex

- 1.4410 Billets & Hex

- ASTM A276 Super Duplex 2507 Hot Rolled Billets

- ASME SA 479 Super Duplex S32760 CR Hex

Our Products

Our Latest Blogs

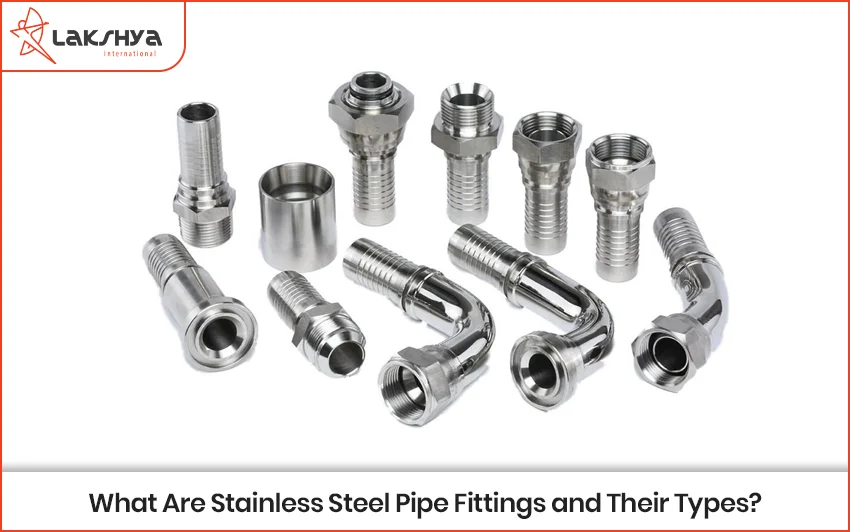

What Are Stainless Steel Pipe Fittings and Their Types?

In order to establish safe and waterproof connections for the movement of liquids, gases, or air, stainless steel pipe fittings serve as crucial components of piping systems. Due to their exceptional strength, durability against corrosion, and endurance, these...

Related Products

Send Us Message

Got a question? We'd love to hear from you. Send us a message & we'll respond as soon as possible.