Duplex Steel Pipes & Tubes

Table of Content

- What is a Duplex Steel Pipe?

- Specification of Duplex Steel Pipes

- Duplex Pipe Composition

- Duplex Stainless Steel Tubes Chemical Composition

- Mechanical Properties for Stainless Steel Duplex Pipes

- Offering Duplex Steel Pipes With Indian Standards

- Duplex Stainless Steel Pipes Equivalent Grades

- Dimension Chart of Duplex Steel Pipes

- Duplex Stainless Steel Pipes Weight Chart

Duplex Stainless Steel Pipes, Duplex Steel Tubes, 2205 Duplex stainless steel Pipe, Duplex Stainless Steel Tubes Supplier. Duplex Steel Seamless Tubes, Duplex Steel Welded Pipes, Duplex Stainless Steel ERW Pipes Suppliers, Manufacturer of Duplex Stainless Steel Pipes & Exporter of Duplex Steel Tubes

What is a Duplex Steel Pipe?

Duplex stainless steel pipes are a type of stainless steel pipe by their unique dual-phase structure, which combines both ferritic and austenitic stainless steel. Its dual composition, usually 50% ferritic and 50% austenitic, provides enhanced strength and resistance.

Duplex stainless steel pipes are known for their excellent resistance to pitting corrosion and their ability to use less nickel compared to other stainless steels. The name “Duplex” refers to the pipe’s dual-phase structure, which enhances its mechanical properties. These pipes are often preferred over austenitic alloys like ASTM A312 TP304 or ASTM A312 TP316 because they offer better corrosion resistance.

Duplex steel pipes, also known as duplex tubes, manufactured to high standards under the Duplex Pipe Code (ASME SA790), these pipes come in various forms, such as duplex steel tubes and stainless steel duplex pipe. Duplex steel tubes are particularly strong due to their high levels of molybdenum, chromium, and nitrogen. They resist chloride pitting, crevice corrosion, and stress corrosion cracking. For example, duplex steel seamless tubes are great for applications needing a high strength-to-weight ratio, while duplex steel round tubes offer the strength of thicker nickel alloys in a lighter form.

Duplex steel welded tubes are resistant to both organic and inorganic acids, making them suitable for tough environments. However, duplex steel EFW tubes & pipes should only be used in applications below 600°F (316°C) due to their temperature limits.

Lakshya Steel – Duplex Steel Pipes Supplier In India

Lakshya Steel is known as the top supplier of high-quality duplex steel pipes in India, catering to a variety of industrial applications. Our Duplex pipes are designed to meet rigorous standards, ensuring exceptional performance. We offer an extensive range of UNS S31803 duplex steel pipes, known for their superior strength and hardness, making them suitable for demanding industrial uses. Additionally, our UNS S32205 duplex steel pipes provide robust corrosion resistance, surpassing that of conventional stainless steels.

For specialized applications, our super duplex steel pipes and tubes, including UNS S23750, UNS S32760, and UNS S32950, are ideal for industries such as chemical processing, oil and gas, marine, food, and pollution control. These super duplex steel seamless pipes are available in various sizes and shapes, adhering to both national and international quality standards.

Lakshya Steel ensures that all our duplex steel seamless pipes are manufactured with high-quality raw materials and can be customized to order, providing flexibility in size and shape with competitive price.

In addition to our comprehensive product range, we also provide custom manufacturing services for duplex stainless welded and ERW pipes. Our manufacturing capabilities extend from 4mm to 219mm in seamless pipes and from 5mm to 1219.2mm in welded pipes. Our team uses the latest technology and rigorous quality control measures to manufacture pipes that meet international standards. As leading duplex steel pipe suppliers in India, Lakshya Steel is committed to delivering reliable, high-quality products tailored to your specific needs. Contact us for durable and precision-engineered duplex steel pipes.

Duplex Steel Pipes, Duplex Steel S31803 Pipes, Duplex Steel S31803 Pipes Manufacturer, Duplex Steel Seamless Pipes, Duplex Steel Welded Pipes, Duplex Steel ERW Pipes, Duplex Steel Pipes Manufacturer, Duplex Steel Pipe Suppliers In Mumbai.

Duplex Steel Tubing From Lakshya Steel

Lakshya Steel is a leading supplier of duplex steel tubes in India, offering a broad range of products to meet diverse industrial needs. Our extensive inventory includes duplex stainless steel tubes in various grades, sizes, and specifications to provide the right solution for your specific needs.

Our duplex steel tubes are ideal for demanding environments such as heat exchangers, desalination plants, and chemical processing facilities. They are renowned for their exceptional corrosion resistance and mechanical strength, making them a reliable choice for critical applications.

As a trusted supplier, we offer top-quality duplex steel tubes with industry standards or customized sizes and specifications. Contact us today for superior duplex steel tubes to discuss your requirements and experience the quality and reliability of our products.

Duplex Steel Seamless Tubes, Duplex Steel Welded Tubes, Duplex Stainless Steel ERW Tubes, Duplex Steel S31803 Tubes Exporter, Duplex Steel Tubing, Duplex Stainless Steel Tubes Supplier In Mumbai India.

Specification of Duplex Steel Pipes

| Standard | : | ASTM / ASME SA 790. SA 789 , SA 790 |

| Grade | : | UNS NO. S 31803, S 32205 |

| Type | : | SEAMLESS / ERW / WELDED/ FABRICATED |

| Length | : | Single Random, Cut Length |

| End | : | Plain End, Bevelled End, Threaded |

Duplex Pipe Composition

Over the past 30 years, improvements in steelmaking have made duplex steel pipes more popular. These pipes have a special structure that mixes two types of steel: austenitic and ferritic. Each type of steel has its own single-phase properties, but when combined, they form a strong two-phase structure with a balanced mix of austenite and ferrite. This blend in duplex stainless steel pipes gives them better strength and resistance to corrosion than regular steels. Duplex pipes are tough and durable, making them great for industrial applications.

|

Common Name |

UNS No |

BS EN No |

Typical Chemical Composition % |

0.2% proof strength N/mm2 (min) |

|||||

| %C | Cr | Ni | Mo | N | Cu | ||||

| 2304 | S32304 | 1.4362 | 0.015 | 23.0 | 4.0 | 0.055 | 0.13 | 400 | |

| 2205 | 2205 | 1.4462 | 0.015 | 22.0 | 5.5 | 3.0 | 0.14 | – | 450 |

| 2205 | S32205 | 1.4462 | 0.015 | 22.5 | 5.5 | 3.3 | 0.17 | 450 | |

| 255(UR52N) | S32520 | 1.4507 | 0.015 | 25.0 | 7.0 | 3-5 | 0.28 | 0.13 | 550 |

| 2507 | S32750 | 1.4410 | 0.015 | 25.0 | 7.0 | 4.5 | 0.28 | 0.3 | 550 |

| Zeron 100 | S32760 | 1.4501 | 0.015 | 25.0 | 7.0 | 3.5 | 0.25 | 0.8 | 550 |

| Sandvik SAF3207 | S33207 | – | 0.03 | 31 | 7.5 | 4.0 | 0.50 | 0.75 | 700 |

Duplex Stainless Steel Tubes Chemical Composition

| Grade | C≤ | Mn≤ | P≤ | S≤ | Si≤ | Ni | Cr | Mo | N | Cu |

| S31803 | 0.03 | 2.00 | 0.03 | 0.02 | 1.00 | 4.5–6.5 | 21.0–23.0 | 2.5–3.5 | 0.08–0.20 | – |

| S32205 | 0.03 | 2.00 | 0.03 | 0.02 | 1.00 | 4.5–6.5 | 22.0–23.0 | 3.0–3.5 | 0.14–0.20 | – |

| S32750 | 0.03 | 1.20 | 0.035 | 0.02 | 0.80 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 | 0.24-0.32 | 0.5 |

| S32760 | 0.05 | 1.00 | 0.03 | 0.01 | 1.00 | 6.0-8.0 | 24.0-26.0 | 3.0-4.0 | 0.20-0.30 | 0.50–1.00 |

Mechanical Properties for Stainless Steel Duplex Pipes

| Grades | Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

| S31803 / S32205 | 7.805 | 0.285 | 1420 – 1465 | 2588 – 2669 |

| S32750 / S32760 | 7.8 | 0.281 | 1350 | 2460 |

Offering Duplex Steel Pipes With Indian Standards

ASTM A789/A789M: This specification covers duplex stainless steel tubing, including grades UNS S31803, S32205, and S32750. These tubes are used in critical applications such as boilers, superheaters, and heat exchangers.

ASTM A789/ASME SA789: This standard pertains to seamless and welded ferritic/austenitic stainless steel tubing suitable for general service. It includes various grades like S31500 (SAF1805), S31803 (SAF2205), S32205 (SAF2205), and S32750 (SAF2507).

These standards ensure that duplex stainless steel pipes and tubes meet high-quality and performance requirements, making them ideal for demanding industrial applications in India.

Duplex Steel Pipe & Tubes Types

Seamless Pipes

ASTM A789 Duplex Steel S31803 Seamless Pipes, S32750 Super Duplex Steel Seamless Pipe, ANSI B36.19 Super Duplex Stainless Steel S32760 Seamless Piping, Ferritic Stainless Steel S31803 Seamless Pipes Supplier, Duplex Stainless Steel 1.4462 Seamless Pipes Exporter.

Welded Pipes

ASTM A790 Duplex stainless Steel S32750 Welded Pipes, S32760 Super Duplex Steel Welded Pipe, ANSI B36.10 Super Duplex Steel S32205 Welded Piping, Ferritic Stainless Steel S32205 Welded Pipes Supplier, Super Duplex Stainless Steel 1.4410 Welded Pipes Exporter.

Seamless Tubes

ASTM A213 Super Duplex Stainless Steel S32760 Seamless Tubes, S31803 Super Duplex Steel Seamless Tubing, ASME SA213 Duplex stainless Steel S32750 Seamless Tubing, Ferritic Stainless Steel S32750 Seamless Tubes Supplier, Duplex steel 1.4462 Seamless Tubes Exporter.

Welded Tubes

ASTM A790 Duplex stainless steel S32750 Welded Tubes, S31803 Super Duplex Steel Welded Tubing, ASME SA790 Ferritic Stainless Steel S31803 Welded Tubing, super Duplex Steel S32760 Welded Tubes Supplier, Super Duplex Stainless Steel 1.4410 Welded Tubes Exporter.

ERW Pipes/Tubes

ASTM A789 Duplex Steel S32760 ERW Pipes, Super Duplex stainless steel S32205 ERW Round Tubing, S32750 Super Duplex Steel ERW Pipes, Ferritic Stainless Steel S31803 ERW Pipes Supplier, Duplex Steel 1.4462 ERW Tubes Exporter.

EFW Pipes

STM A790 Super Duplex Stainless steel S32750 EFW Pipes, ANSI B36.19 Super Duplex Stainless Steel S31803 EFW Piping, S32750 Super Duplex Steel EFW Pipes, Ferritic Stainless Steel S32750 EFW Pipes Supplier, Duplex Stainless Steel 1.4410 EFW Pipes Exporter.

Duplex Stainless Steel Pipe Grades

Duplex Stainless Steel Pipes Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS |

| Duplex 2205 | 1.4462 | S31803 / S32205 |

| Super Duplex 2750 | 1.4410 | S32750 / S32760 |

Customized Duplex Pipes

Customized Duplex Pipes offer exceptional durability and strength, especially in environments exposed to corrosive compounds like chloride stress and pitting corrosion. These pipes are designed with high tensile strength, surpassing that of standard austenitic stainless steel grades.The lower nickel content in duplex pipes contributes to their economical nature while maintaining robustness and resilience. As a leading distributor and manufacturer of Duplex Stainless Steel Pipes, we provide high-quality products tailored to your specifications.

Duplex Stainless Steel Pipe sizes

Duplex Stainless Steel Seamless Pipe

Size: 4 – 219mm

Thickness : 0.5 – 20mm

Length: Single, Double Random & Cut Length

Duplex Steel Welded Pipe

Size: 5.0 – 1219.2 mm

Thickness : 0.5 – 20mm

Length: Single, Double Random & Cut Length

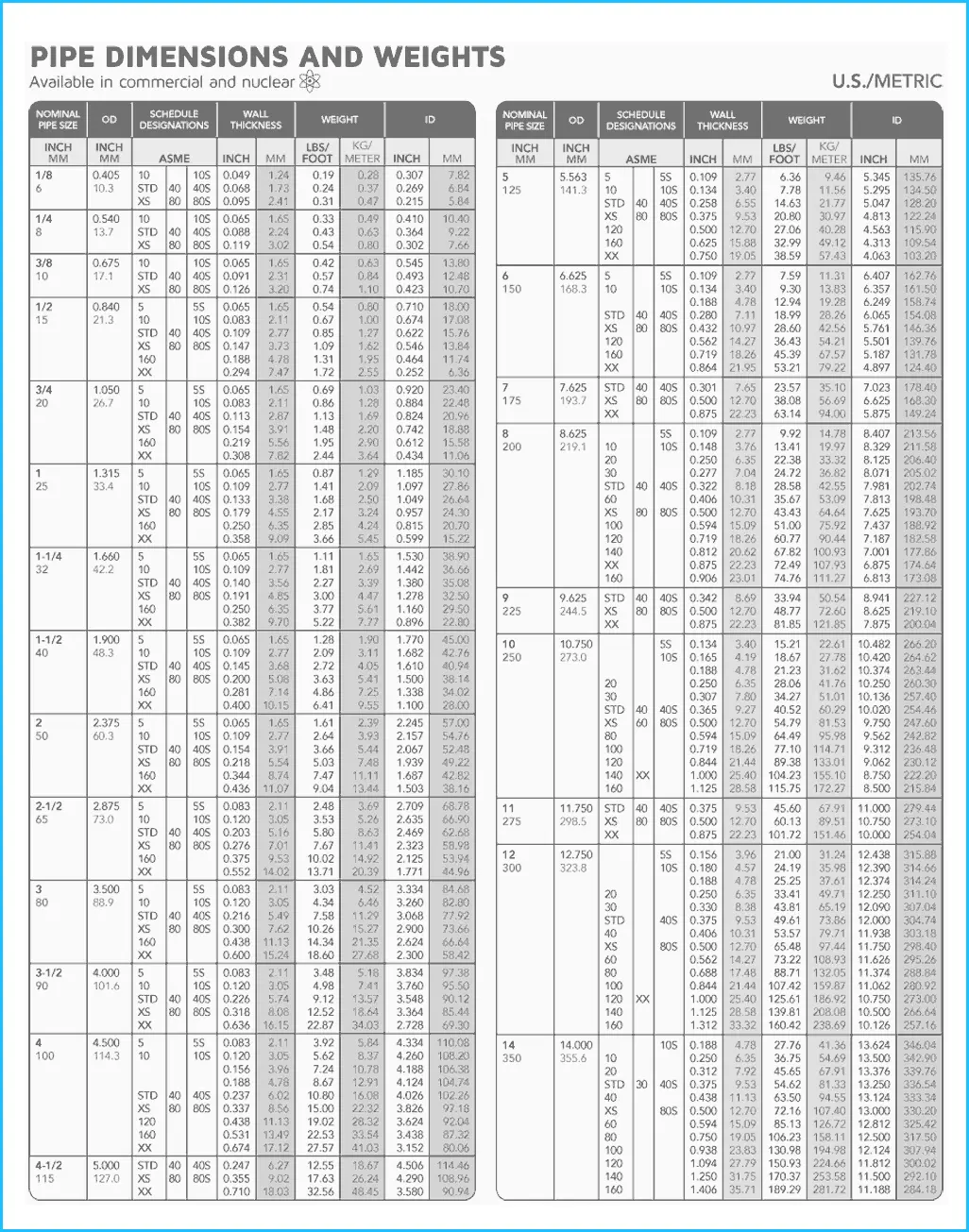

Dimension Chart of Duplex Steel Pipes

| Specification | : | ASTM A 790 ASME SA 790 |

| Dimensions | : | ASTM, ASME and API |

| Size | : | 1/2″ TO 6′ IN OD & NB IN Various SWG & SCH |

| Specialized in | : | Large Diameter Size |

| Schedule | : | SCH20, SCH30, SCH40, STD, SCH80 |

| Type | : | Seamless / Welded / ERW / Fabricated |

| Form | : | Round, Hydraulic, Etc. |

| Length | : | Single Random, Double Random & Cut Length. |

| End | : | Plain End, Beveled End, Threaded |

| Test | : |

|

Duplex Stainless Steel Pipes Weight Chart

Surface Finish of Duplex Steel Seamless Tubes

| Surface Finish | Internal Surface(ID) | Exterbal Surface(OD) | |||

|---|---|---|---|---|---|

| Roughness Average(RA) | Roughness Average(RA) | ||||

| μ inch | μm | μ inch | μm | ||

| AP | Annealed & Pickled | Not defined | Not defined | 40 or Not defined | 1.0 or Not defined |

| BA | Beight Annealed | 40,32,25,20 | 1.0,0.8,0.6,0.5 | 32 | 0.8 |

| MP | Mechanical Polish | 40,32,25,20 | 1.0,0.8,0.6,0.5 | 32 | 0.8 |

| EP | Electro Polish | 15,10,7,5 | 0.38,0.25,0.20;0.13 | 32 | 0.8 |

Duplex Steel Pipe Pressure Rating

| Tube O.D. (in.) |

Wall Thickness of Tube (inches) | |||||||

|---|---|---|---|---|---|---|---|---|

| .028 | .035 | .049 | .065 | .083 | .095 | .109 | .120 | |

| Working Pressure (psig) | ||||||||

| 1/8 | 7900 | 10100 | ||||||

| 1/4 | 3700 | 4800 | 7000 | 9500 | ||||

| 5/16 | 3700 | 5400 | 7300 | |||||

| 3/8 | 3100 | 4400 | 6100 | |||||

| 1/2 | 2300 | 3200 | 4400 | |||||

| 3/4 | 2200 | 3000 | 4000 | 4600 | ||||

| 1 | 2200 | 2900 | 3400 | 3900 | 4300 | |||

Duplex Stainless Steel Pipe Schedule Chart

| 1/8″ IPS(.405″ O.D.) | 3 1/2″ IPS( 4.000″ O.D.) |

|---|---|

| Seamless Pipes, SCH 40, 80 | Pipes, SCH 10, 40, 80, 160, XXH |

| 1/4″ IPS(.540″ O.D.) | 4″ IPS(4.500″ O.D.) |

| Pipes, SCH 10, 40, 80 | Seamless Pipes, SCH 10, 40, 80, 160, XXH |

| 3/8″ IPS(.675″ O.D.) | 5″ IPS( 5.563″ O.D.) |

| Seamless Pipes, SCH 10, 40, 80 | Pipes, SCH 10, 40, 80, 160, XXH |

| 1/2″ IPS(.840″ O.D.) | 6″ IPS(6.625″ O.D.) |

| Seamless Pipes, SCH 5, 10, 40, 80, 160, XXH | Seamless Pipes, SCH 5, 10, 40, 80, 120, 160, XXH |

| 3/4″ IPS(1.050″ O.D.) | 8 ” IPS(8.625″ O.D.) |

| Pipes, SCH 10, 40, 80, 160, XXH | Stainless Pipes, SCH 5, 10, 40, 80, 120, 160, XXH |

| 1″ IPS:(1.315′ O.D.) | 10″ IPS(10.750″ O.D.) |

| Seamless Pipes, SCH 5, 10, 40, 80, 160, XXH | Pipes, SCH 10, 20, 40, 80 (.500), TRUE 80(.500) |

| 1-1/4″ IPS(1.660″ O.D.) | 12″ IPS(12.750″ O.D.) |

| Seamless Pipes, SCH 10, 40, 80, 160, XXH | Pipes, SCH 10, 20, 40(.375), TRUE40(.406), SCH80(.500) |

| 1-1/2″ IPS(1.900″ O.D.) | 14″ IPS(14.000″ O.D.) |

| Seamless Pipes, SCH 10, 40, 80, 160, XXH | Pipes, SCH10 (.188), SCH40 (.375) |

| 2″ IPS(2.375″ O.D.) | 16″ IPS(16.000″ O.D.) |

| Seamless Pipes, SCH 10, 40, 80, 160, XXH | Pipes, SCH10(.188), SCH40(.375) |

| 2 1/2″ IPS(2.875″ O.D.) | 18″ IPS (18.000″ O.D.) |

| Seamless Pipes, SCH 10, 40, 80, 160, XXH | Pipes, SCH-40 (.375) |

| 3″ IPS( 3.500″ O.D.) | |

| Seamless Pipes, SCH 5, 10, 40, 80, 160, XXH |

Benefits of Duplex Steel Pipes

- Genuine Material & Cost-Effective: Buy directly from the manufacturer for authentic, competitively priced pipes with fast global delivery.

- Enhanced Strength: Offers double the design strength of austenitic and ferritic steels for superior performance.

- Machining & Forming: More challenging to machine but highly durable and strong.

- Weldability: Can be welded with care, especially in thicker materials, for reliable joints.

- Temperature Tolerance: Effective up to 300°C, with excellent toughness down to -80°C (not suitable for cryogenic use).

- Corrosion Resistance: Tailored corrosion resistance for various applications.

- Stress Corrosion Cracking: Outstanding resistance, ideal for demanding environments.

Applications of Duplex Pipes

- Offshore Oil Drilling: Withstands harsh offshore conditions.

- Petrochemical Plants: Essential for various processes.

- DSS Pipes: Ideal for oil and gas production and transport.

- Condensers: Efficient in heat exchange systems.

- Power Generation: Durable and resistant in power plants.

- Gas Processing: Handles and processes gases effectively.

- Heat Exchangers: Efficient heat transfer between fluids.

- Structural Components: Provides strength for structural uses.

- Cooling Pipes: Manages thermal systems efficiently.

- Sea Water Equipment: Corrosion-resistant for marine applications.

- Chemical & Pharmaceutical Equipment: Reliable and resistant in manufacturing.

New York City, Los Angeles, Chicago, Houston, Phoenix, Philadelphia, San Antonio, San Diego, Dallas, San Jose, Austin, Jacksonville, Fort Worth, Columbus, Charlotte, San Francisco, Indianapolis, Seattle, Denver, Washington, Boston, El Paso, Nashville, Detroit, Oklahoma City, Portland, Las Vegas, Memphis, Louisville, Baltimore, Milwaukee, Albuquerque, Tucson, Fresno, Mesa, Sacramento, Atlanta, Kansas City, Colorado Springs, Omaha, Raleigh, Miami, Long Beach, Virginia Beach, Oakland, Minneapolis, Tulsa, Tampa, Arlington, New Orleans, Wichita, Bakersfield, Cleveland, Aurora, Anaheim, Honolulu, Santa Ana, Riverside, Corpus Christi, Lexington, Henderson, Stockton, Saint Paul, Cincinnati, St. Louis, Pittsburgh, Greensboro, Lincoln, Anchorage, Plano, Orlando, Irvine, Newark, Durham, Chula Vista, Toledo, Fort Wayne, St. Petersburg, Laredo, Jersey City, Chandler, Madison, Lubbock, Scottsdale, Reno, Buffalo, Gilbert, Glendale, North Las Vegas, Winston-Salem, Chesapeake, Norfolk, Fremont, Garland, Irving, Hialeah, Richmond, Boise, Spokane, Baton Rouge, Tacoma, San Bernardino, Modesto, Fontana, Des Moines, Moreno Valley, Santa Clarita, Fayetteville, Birmingham, Oxnard, Rochester, Port St. Lucie, Grand Rapids, Huntsville, Salt Lake City, Frisco, Yonkers, Amarillo, Glendale, Huntington Beach, McKinney, Montgomery, Augusta, Aurora, Akron, Little Rock, Tempe, Columbus, Overland Park, Grand Prairie, Tallahassee, Cape Coral, Mobile, Knoxville, Shreveport, Worcester, Ontario, Vancouver, Sioux Falls, Chattanooga, Brownsville, Fort Lauderdale, Providence, Newport News, Rancho Cucamonga, Santa Rosa, Peoria, Oceanside, Elk Grove, Salem, Pembroke Pines, Eugene, Garden Grove, Cary.

FAQs

What is a duplex tube?

What grade is used for duplex steel pipes?

What are half duplex and full duplex pipes?

Our Products

Our Latest Blogs

What is Low Alloy Steel? – Properties, Uses, Grades & Composition

Steel is one of the most versatile materials in the world, and among its many variations, low alloy steel holds a unique place due to its excellent balance of strength, toughness, and cost-effectiveness. But what exactly is low alloy steel, and how does it differ from...

Related Products

- Stainless Steel 304 Single Slotted Pipe

- Stainless Steel 304 Double Slotted Pipe

- Stainless steel 304 fittings

- Stainless Steel 304 Components

- Stainless Steel 309 Rod/Bar

- Stainless Steel 309 Hex Bar

- Stainless Steel 309 Square Bar

- Stainless Steel 309 Welded Pipes

- Stainless Steel 309 Plates Sheet

- Stainless steel 309 fittings

- Stainless Steel 309 Components

- Stainless Steel 310 Rod / Bar

- Stainless steel 310 Hex Bars

- Stainless Steel 310 Square Bar

- Stainless Steel 310 Welded Pipes

- Stainless Steel 310 Plates/Sheet

- Stainless Steel 310 Seamless Pipes

- Stainless steel 310 Welded Tubes

- Stainless steel 310 fittings

- Stainless steel 310 channels

- Stainless steel 310 H Beam

- Stainless steel 310 I Beam

- Stainless steel 310 seamless tubes

- Stainless Steel 310 Components

- Stainless Steel 316 / 316Ti Flanges

- Stainless Steel 316 / 316Ti Rod

- Stainless Steel 316 / 316Ti Hex Bars

- Stainless Steel 316 / 316Ti Square Bars

- Stainless Steel 316 / 316Ti Seamless Pipes

- Stainless Steel 316 / 316Ti Welded Pipes

- Stainless Steel 316 / 316Ti Plates

- Stainless Steel 316 / 316Ti Welded Tubes

- Stainless Steel 316 / 316Ti Seamless Tubes

- Stainless Steel 316 / 316Ti Flat Bars

- Stainless Steel 316 / 316Ti Angles

- Stainless Steel 316 / 316Ti Channels

- Stainless Steel 316 / 316Ti H Beams

- Stainless Steel 316 / 316Ti I Beam

- Stainless Steel 316 / 316Ti Pipe Fittings

- Stainless Steel 316 Single Slotted Pipe

- Stainless Steel 316 Double Slotted Pipe

- Stainless Steel 316/316Ti Components

- Stainless Steel 317L Flanges

- Stainless Steel 317L Rod/Bar

- Stainless Steel 317L Hex Bar

- Stainless steel 317L Square Bar

- Stainless Steel 317L Plates/Sheet

- Stainless steel 317L channels

- Stainless steel 317L H Beam

- Stainless steel 317L I Beam

- Stainless steel 317L fittings

- Stainless Steel 317L Components

- Stainless Steel 321 / 347 Flanges

- Stainless Steel 321/347 Rod/Bar

- Stainless Steel 321/347 Hex Bar

- Stainless Steel 321/347 Square Bar

- Stainless Steel 321/347 Seamless Pipes

- Stainless Steel 321/347 Welded Pipes

- Stainless Steel 321 / 347 Pipe Fittings

- Stainless Steel 321/347 Plates/Sheet

- Stainless steel 321 / 347 Welded Tubes

- Stainless steel 321 / 347 seamless tubes

- Stainless steel 321 / 347 channels

- Stainless steel 321 / 347 H Beam

- Stainless steel 321 / 347 I Beam

- Stainless Steel 321 / 347 Components

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 Flange

- Stainless Steel 409/409M/409L/410/430/430F/431/439/441 Rod/Bars

- Stainless Steel 409/409M/409L/410/430/430F/431/439/441 Hex Bar

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 Square Bar

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 Welded Pipes

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 Sheet /Plates/Coil

- Stainless Steel 409/409M/409L/410/430/430F/431/439/441 Welded tubes

- Stainless Steel 409/409M/409L/410/430/430F/431/439/441 Channel

- Stainless Steel 409/409M/409L/410/430/430F/431/439/441 H Beam

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 I Beam

- Stainless Steel 409 / 409M / 409L / 410 / 430 / 430F / 431 / 439 / 441 Components

- Stainless Steel 420/ 420B & 420C Rod/Bar

- Stainless steel 420 / 420B & 420C hex bars

Send Us Message

Got a question? We'd love to hear from you. Send us a message & we'll respond as soon as possible.