Carbon Steel Products Manufacturer & Supplier in India

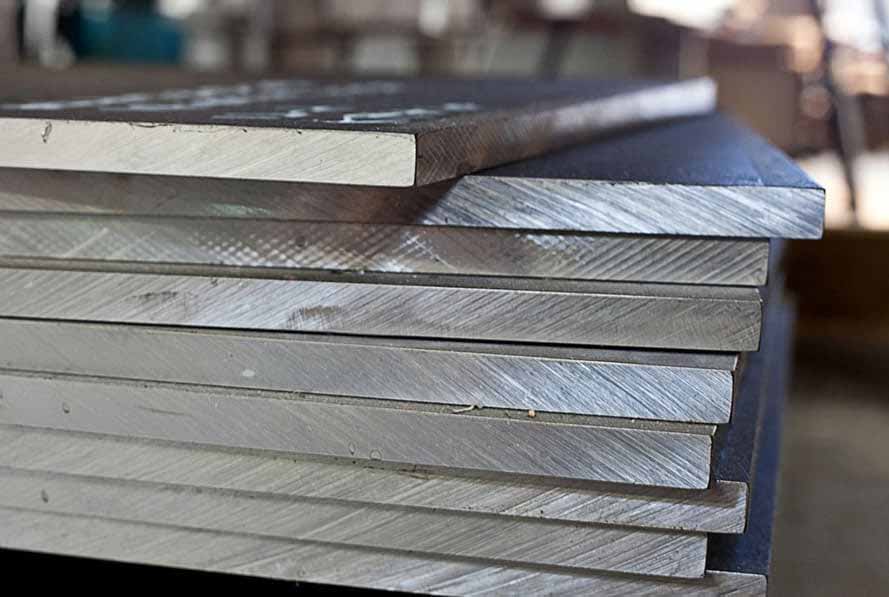

As one of the leading manufacturers of carbon steel products in India, Lakshya International takes pride in delivering excellence in every product we offer. We provide an extensive range of carbon steel products designed to meet the diverse needs of various industries, including Carbon Steel Fittings, Pipes, Flanges, Fasteners, Line Pipes, and ASTM A36. Additionally, we supply S275 Carbon Steel Plates, E350C Hot Rolled Steel Plates, S235JR Carbon Steel Plates, S355JR Plates, EN 10025 S355J2 N Plates, as well as E250BR Sheets and Plates. Whether you require standard sizes or custom specifications, our carbon steel products are engineered to deliver exceptional performance and durability.

As trusted carbon steel manufacturers in India, we adhere to stringent quality standards to ensure that our products meet the highest industry benchmarks. Our state-of-the-art manufacturing facilities and experienced team enable us to produce carbon steel products that exceed customer expectations. In addition to serving the domestic market, Lakshya International is also a trusted exporter of carbon steel products, catering to clients worldwide. With our commitment to quality, reliability, and customer satisfaction, we have earned a reputation as a preferred supplier of carbon steel products on the global stage.

Contact us to connect with our team of experts

Carbon Steel Products Lists

Types of Carbon Steel

|

Carbon contents (wt.%) |

Physical Properties |

Common grades example |

|

|

Low-carbon steel (Pearlite / Ferrite) |

< 0.25 |

Low cost/hardness. High machinability, ductility, toughness, and welding ability |

AISI 304, ASTM A815/ SAA815, AISI 316L |

|

Medium-carbon steel (Martensite) |

.25 to 0.60 |

Low hardness, medium ductility, strength, and toughness |

AISI 409, ASTM A29/ SA29, SCM435 |

|

High-carbon steel (Pearlite) |

.60 to 1.25 |

High strength and hardness but low ductility |

EN 10088-3, AISI 440C |

Carbon Steel Properties

|

Alloy Type |

AISI |

Carbon content (wt.%) |

Yield strength (MPa) |

Tensile strength (MPa) |

Ductility (% elongation in 50 mm) |

Common Uses |

|

Low |

1010 |

0.1 |

180 |

325 |

28 |

Automobile panels, nails, wire |

|

Low |

1020 |

0.2 |

205 |

380 |

25 |

structural steel, Pipe, sheet steel |

|

Low |

A36 |

0.29 |

220 |

400 |

23 |

Structural alloy |

|

Low |

A516 Gr 70 |

0.31 |

260 |

485 |

21 |

LTCS pressure vessels |

|

Medium |

1030 |

.27 – .34 |

325 |

460 |

12 |

Gears, machinery items, shifts, axles, bolts |

|

Medium |

1040 |

.37 – .44 |

415 |

620 |

25 |

coupling, crankshafts, cold headed parts. |

|

High |

1080 |

.75 – .88 |

440 |

924 |

12 |

Music wire |

|

High |

1095 |

.90 – 1.04 |

380 |

665 |

10 |

Carbon Steel Composition

Low Carbon Steel Grade Chemical Formula

|

Grade |

UNS Number |

S (max) |

C (max) |

P (max) |

Mn (max) |

Si |

Cr |

Ni |

Mo |

|

1010 |

G10100 |

0.05% |

.08-.13% |

0.04% |

.30-.60% |

– |

– |

– |

– |

|

1018 |

G10180 |

0.05% |

.14-.20% |

0.04% |

.60-.90% |

– |

– |

– |

– |

|

1020 |

G10200 |

0.05% |

.17-.23% |

0.04% |

.30-.60% |

– |

– |

– |

– |

|

1022 |

G10220 |

0.05% |

.17-.23% |

0.04% |

.70-1.00% |

– |

– |

– |

– |

Medium Carbon Steel Material Chemical Properties

| Grade | UNS

Number |

Mn

(max) |

S

(max) |

C

(max) |

P

(max) |

Si | Cr | Ni | Mo |

| 1010 | G10100 | .30-.60% | 0.05% | .08-.13% | 0.04% | – | – | – | – |

| 1018 | G10180 | .60-.90% | 0.05% | .14-.20% | 0.04% | – | – | – | – |

| 1020 | G10200 | .30-.60% | 0.05% | .17-.23% | 0.04% | – | – | – | – |

| 1022 | G10220 | .70-1.00% | 0.05% | .17-.23% | 0.04% | – | – | – | – |

Carbon Steel Grades

Low Carbon Steel Grades

| Grade | UNS Designation number |

| 1010 | G10100 |

| 1018 | G10180 |

| 1020 | G10200 |

| 1022 | G10220 |

Medium Carbon Steel Grades

| Grade | UNS Designation number |

| 1030 | G10300 |

| 1040 | G10400 |

| 1045 | G10450 |

| 1060 | G10600 |

Frequently used Carbon Steel ASTM Grades:

| Pipes | |

| ASTM A53/A53M/ SA 53 | ASTM A106/A106M / SA 106 |

| ASTM A134 / SA 134 | ASTM A135/A135M / SA 135 |

| ASTM A139/A139M / SA 139 | ASTM A671 / S A671 |

| ASTM A672 / SA672 | ASTM A333 Grade 6 /3/ SA333 |

| Piping Connection | |

| A350 LF2/ SA 350 | A105 / SA105 |

| A694 / SA694 | A234 WPB / SA234 |

| A420 WPL6 / SA420 | A860 (WPHY) / SA860 |