Information

ASTM A182 F12 Round Bar, F12 Bar, F12 Alloy Bars, A182 F12 Bars Supplier & Manufacturer, Astm A182 Gr F12 Round Bar, Sa182 F12 Round Bar, ASTM A182 F12 Cl2 Round Bar, ASME SA 182 F12 Class 1 / 2 Round Bar Manufacturer In India, ASTM A182 F12 Alloy Steel Round Bar, Grade ASTM A182 Alloy Steel F12 Bright Bar, AS A182 Gr. F12 Rods, ASTM A182 Gr F12 Alloy Steel Polished Bars, ASTM A182 F12 Alloy Steel Rods Stockholder, Manufacturer in India, ASTM A182 F12 Alloy Steel Square Bars, Alloy Steel F12 Hot Rolled Bar, A182 F12 Cold Finished Bars Dealer, Alloy Steel Grade F12 Rectangular Bar, ASTM A276 Grade F12 Black Bar Exporter & Supplier in India.

SA182 F11, ASTM A182 F12, A182 F12, SA 182 F12. Chrome Moly A182 F12 Bars, Alloy Steel ASTM A182 F12 Forged Bar, Chrome Moly Bar Stock, Alloy Steel Grade F12 Bar Exporter, ASTM A182 Gr F12 Class 1 Hex Bars, ASTM A182 F12 Equivalent, Chrome Moly ASTM A182 F12 Round Bar, SA 182 F12 Chemical Composition, ASTM A182 F12 Class 1 Bright Bar, ASTM A182 Gr F12 Bars, A182 F12 Class 2 Bars Dealer, CrMo Grade F12 Class 1 Bars, Alloy Steel 1.7335 Forged Bar, F12 Alloy Steel Rectangular Bar, ASTM A182 Alloy Steel F12 Flat Bar, ASTM A182 Chrome Moly F12 Rods Exporter, ASTM A182 Alloy Steel F12 Hex Bar Supplier, Alloy Steel K11562 Square Bar, Alloy Steel F12 Bright Bar, Alloy Steel F12 Round Bar Manufacturer in India.

ASTM A182 F12 Round Bar

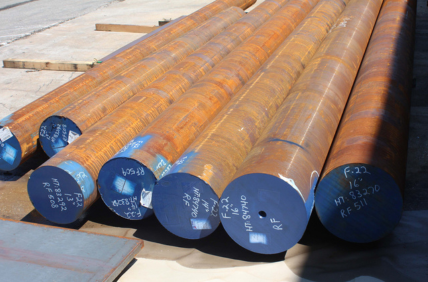

Lakshya International is a highly reputed exporter and supplier of top-notch ASTM A182 F12 Alloy Steel Round Bars, meticulously sourced from superior quality raw materials. These Alloy Steel A182 F12 Rods guarantee exceptional toughness, meeting the highest industry standards. Our core strength lies in providing a technically upgraded range of ASTM A182 F12 Round Bars, widely utilized in various process industries and industrial setups. The SA182 F12 Alloy Steel Rods find extensive applications in the automotive and other sectors due to their unparalleled quality and exceptional features. At Lakshya International, we offer various types of these bars, including Alloy Steel ASTM A182 F12 Bright Bars, Alloy Steel ASTM A182 F12 Hex Bars, Alloy Steel ASTM A182 F12 Black Bars, Alloy Steel ASTM A182 F12 Flat Bars, Alloy Steel ASTM A182 F12 Billets Bars, and Alloy Steel ASTM A182 F12 Forged Bars. Each variant is designed to cater to specific needs and requirements, ensuring utmost customer satisfaction.

Alloying metals during the processing of alloys often results in improved performance. In the case of alloy steel components, such as ASTM A182 Gr F12 Alloy Steel Hex Bars produced under ASME SA 182 specifications, various processing techniques like hot rolling, forging, and polishing are commonly employed. Polishing plays a crucial role in enhancing the corrosion resistance properties of Grade F12 Cr-Mo A182 Polished Bars. Additionally, the abrasive used during polishing helps eliminate oxidization and achieve a smoother surface. Forging, on the other hand, is primarily utilized to improve the impact resistance of ASTM A182 F12 Round Bars, leading to enhanced fatigue resistance. Furthermore, the aligned grain flow in SA182 Chrome Moly Gr. F12 Forged Bars contributes to improved ductility.

When compared to hot rolled products, the strength of Grade ASTM A182 Alloy Steel F12 Cold Finished Bars is approximately 20 percent higher. These bars exhibit high structural integrity due to the processing temperature being above ambient temperature. For applications where cost control and efficient use of raw materials are essential, buyers often prefer Alloy Steel Grade F12 Hot Rolled Bars. Another advantage of hot rolling is the relatively lower resistance to metal plastic deformation in the Alloy Steel A182 F12 Threaded Bars.

CITIES WE DELIVERED

New York City, Los Angeles, Chicago, Houston, Phoenix, Philadelphia, San Antonio, San Diego, Dallas, San Jose, Austin, Jacksonville, Fort Worth, Columbus, Charlotte, San Francisco, Indianapolis, Seattle, Denver, Washington, Boston, El Paso, Nashville, Detroit, Oklahoma City, Portland, Las Vegas, Memphis, Louisville, Baltimore, Milwaukee, Albuquerque, Tucson, Fresno, Mesa, Sacramento, Atlanta, Kansas City, Colorado Springs, Omaha, Raleigh, Miami, Long Beach, Virginia Beach, Oakland, Minneapolis, Tulsa, Tampa, Arlington, New Orleans, Wichita, Bakersfield, Cleveland, Aurora, Anaheim, Honolulu, Santa Ana, Riverside, Corpus Christi, Lexington, Henderson, Stockton, Saint Paul, Cincinnati, St. Louis, Pittsburgh, Greensboro, Lincoln, Anchorage, Plano, Orlando, Irvine, Newark, Durham, Chula Vista, Toledo, Fort Wayne, St. Petersburg, Laredo, Jersey City, Chandler, Madison, Lubbock, Scottsdale, Reno, Buffalo, Gilbert, Glendale, North Las Vegas, Winston-Salem, Chesapeake, Norfolk, Fremont, Garland, Irving, Hialeah, Richmond, Boise, Spokane, Baton Rouge, Tacoma, San Bernardino, Modesto, Fontana, Des Moines, Moreno Valley, Santa Clarita, Fayetteville, Birmingham, Oxnard, Rochester, Port St. Lucie, Grand Rapids, Huntsville, Salt Lake City, Frisco, Yonkers, Amarillo, Glendale, Huntington Beach, McKinney, Montgomery, Augusta, Aurora, Akron, Little Rock, Tempe, Columbus, Overland Park, Grand Prairie, Tallahassee, Cape Coral, Mobile, Knoxville, Shreveport, Worcester, Ontario, Vancouver, Sioux Falls, Chattanooga, Brownsville, Fort Lauderdale, Providence, Newport News, Rancho Cucamonga, Santa Rosa, Peoria, Oceanside, Elk Grove, Salem, Pembroke Pines, Eugene, Garden Grove, Cary, Fort Collins, Corona, Springfield, Jackson, Alexandria, Hayward, Clarksville, Lakewood, Lancaster, Salinas, Palmdale, Hollywood, Springfield, Macon, Kansas City, Sunnyvale, Pomona, Killeen, Escondido, Pasadena, Naperville, Bellevue, Joliet, Murfreesboro, Midland, Rockford, Paterson, Savannah, Bridgeport, Torrance, McAllen, Syracuse, Surprise, Denton, Roseville, Thornton, Miramar, Pasadena, Mesquite, Olathe, Dayton, Carrollton, Waco, Orange, Fullerton, Charleston, West Valley City, Visalia, Hampton, Gainesville, Warren, Coral Springs, Cedar Rapids, Round Rock, Sterling Heights, Kent, Columbia, Santa Clara, New Haven, Stamford, Concord, Elizabeth, Athens, Thousand Oaks, Lafayette, Simi Valley, Topeka, Norman, Fargo, Wilmington, Abilene, Odessa, Columbia, Pearland, Victorville, Hartford, Vallejo, Allentown, Berkeley, Richardson, Arvada, Ann Arbor, Rochester, Cambridge, Sugar Land, Lansing, Evansville, College Station, Fairfield, Clearwater, Beaumont, Independence, Provo, West Jordan, Murrieta, Palm Bay, El Monte, Carlsbad, North Charleston, Temecula, Clovis, Springfield, Meridian, Westminster, Costa Mesa, High Point, Manchester, Pueblo, Lakeland, Pompano Beach, West Palm Beach, Antioch, Everett, Downey, Lowell, Centennial, Elgin, Richmond, Peoria, Broken Arrow, Miami Gardens, Billings, Jurupa Valley, Sandy Springs, Gresham, Lewisville, Hillsboro, Ventura, Greeley, Inglewood, Waterbury, League City, Santa Maria, Tyler, Davie, Lakewood, Daly City, Boulder, Allen, West Covina, Sparks, Wichita Falls, Green Bay, San Mateo, Norwalk, Rialto, Las Cruces, Chico, El Cajon, Burbank, South Bend, Renton, Vista, Davenport, Edinburg, Tuscaloosa, Carmel, Spokane Valley, San Angelo, Vacaville, Clinton, Bend, Woodbridge.

View Latest Price & Ready Sizes Of ASMT A182 F12, SA182 Chrome Moly Gr.F12 Forged Bar, Pump Shaft & Hexagonal Bar Ex Mumbai & Kalamboli

Specification Of ASTM A182 Grade F12 Alloy Steel Round Bar:

|

type |

Alloy Steel ASTM A182 F12 Round Bars |

|

Type |

Round bar, threaded bar, square bar, rod, hexagon bar, channel bar, flat bar, angle bar |

|

Range |

3.17 to 350mm diameter |

|

Surface |

pickled round bar, bright round bar, black round bar |

|

Standards |

Alloy Steel A479, ASTM A182 F12 , A314, GB/T1220-2007, GB4226-84, JIS G4318-98, JISG4311-91, GB4226-84, EN 10095-99, JIS G3033-2005, EN10088-3-2005 etc |

|

Technique |

Hot Rolled/Forged/Peeled/Cold Drawn |

|

Diameter |

5 to 500mm Custom size |

|

Length |

1 to 9m or custom size |

Condition

H&T |

Hardened and tempered. |

ANN |

Annealed |

PH |

Precipitation hardened. |

Surface finish

CG |

Centreless ground |

HF |

Hot finished |

CF |

Cold finished |

HRAP |

Hot rolled annealed and pickled |

P&T |

Peeled and turned |

RT |

Rough turned/peeled |

CD |

Cold drawn |

P |

Polished |

BD |

Bright drawn |

SRE |

Slit rolled edge |

ST |

Smooth turned |

PR |

Peeled and reeled |

Chemical Composition of ASTM A182 F12 AS Round Bar:

| Grade | P | Mn | C | Mo | Si | Cr |

| ASTM A182 F12 | 0.025 | 0.40 – 0.65 | 0.10 – 0.20 | 0.44 – 0.65 | 0.50 – 0.80 | 1.00 – 1.50 |

ASTM A182 F12 Chrome Moly Bars Mechanical Properties:

| Elongation (% in 50mm) min | Yield Strength 0.2% Proof (ksi) min | Tensile Strength (ksi) min |

| 30 | 205 | 415 |

Equivalent Material of ASTM A182 Grade F12 Bar:

|

STANDARD |

UNS |

WERKSTOFF NR. |

|

ASTM A182 F12 |

– |

– |

Alloy Stell Gr F12 Round Bar Sizes:

| Type | SIZES (mm) | SIZES (Inches) | ISO Tolerance |

| Cold Drawn and Ground | 10.00 – 75.00 | 5/6″ – 2.50″ | h8-h9-h10-h11 |

| Cold Drawn and Polish | 3.00 – 75.00 | 1/8″ – 3.00″ | h8-h9-h10-h11 |

| Peeled and Polished | 40.00 – 150.00 | 1.50″ – 6.00″ | h11, h11-DIN 1013 |

| Peeled and Ground | 20.00 – 50.00 | 3/4″ – 2.00″ | h9-h10-h11 |

Alloy Steel Grade F12 Bars Standard lengths of 2000 mm up to 6000 mm. Cut to size on request (tolerance +2/-0 mm).

| 5.0 | 45.0 |

| 6.0 | 50.0 |

| 7.0 | 55.0 |

| 8.0 | 60.0 |

| 9.0 | 65.0 |

| 10.0 | 70.0 |

| 12.0 | 75.0 |

| 16.0 | 80.0 |

| 20.0 | 90.0 |

| 25.0 | 100.0 |

| 30.0 | 130.0 |

| 35.0 | 160.0 |

| 40.0 | 200.0 |

Weight Chart of ASTM A182 F12 Round Bars:

|

SHAPE |

POUNDS PER FOOT |

|

Flat |

Thickness (in.) x Width (in.) x 3.4 |

|

Hexagon |

D2 x 2.945 |

|

Round |

D2 x 2.67 |

|

Square |

D2 x 3.4 |

Weight Chart of Chrome Moly F12 Forged Bars:

| SIZE IN INCHES | ROUND | OCTAGON | SQUARE | HEXAGON | SIZE IN INCHES | HEXAGON | SQUARE | ROUND | OCTAGON |

| 1/16 | .010 | .011 | .013 | .012 | 11/16 | 1.392 | 1.607 | 1.262 | 1.333 |

| 5/64 | .017 | .018 | .022 | .019 | 45/64 | 1.456 | 1.681 | 1.320 | 1.394 |

| 3/32 | .023 | .024 | .029 | .025 | 23/32 | 1.521 | 1.756 | 1.380 | 1.487 |

| 7/64 | .031 | .033 | .039 | .034 | 47/64 | 1.588 | 1.834 | 1.440 | 1.521 |

| 1/8 | .042 | .044 | .053 | .046 | 3/4 | 1.656 | 1.913 | 1.502 | 1.586 |

| 9/64 | .053 | .056 | .067 | .058 | 25/32 | 1.797 | 2.075 | 1.630 | 1.721 |

| 5/32 | .065 | .069 | .083 | .072 | 13/16 | 1.944 | 2.245 | 1.763 | 1.862 |

| 11/64 | .079 | .083 | .100 | .087 | 27/32 | 2.096 | 2.421 | 1.901 | 2.008 |

| 3/16 | .094 | .099 | .120 | .104 | 7/8 | 2.254 | 2.603 | 2.045 | 2.159 |

| 13/64 | .110 | .116 | .140 | .121 | 29/32 | 2.418 | 2.792 | 2.193 | 2.316 |

| 7/32 | .128 | .135 | .163 | .141 | 15/16 | 2.588 | 2.988 | 2.347 | 2.479 |

| 15/64 | .147 | .155 | .187 | .162 | 31/32 | 2.763 | 3.191 | 2.506 | 2.646 |

| 1/4 | .167 | .176 | .213 | .184 | 1 | 2.945 | 3.400 | 2.670 | 2.820 |

| 17/64 | .188 | .199 | .240 | .207 | 1-1/16 | 3.324 | 3.838 | 3.015 | 3.183 |

| 9/32 | .211 | .223 | .269 | .233 | 1-1/8 | 3.727 | 4.303 | 3.380 | 3.569 |

| 19/64 | .235 | .248 | .300 | .259 | 1-3/16 | 4.152 | 4.795 | 3.766 | 3.977 |

| 5/16 | .261 | .275 | .332 | .288 | 1-1/4 | 4.601 | 5.313 | 4.172 | 4.407 |

| 21/64 | .288 | .304 | .360 | .318 | 1-5/16 | 5.072 | 5.857 | 4.600 | 4.858 |

| 11/32 | .316 | .334 | .402 | .348 | 1-3/8 | 5.567 | 6.428 | 5.049 | 5.332 |

| 23/64 | .345 | .364 | .439 | .381 | 1-7/16 | 6.085 | 7.026 | 5.518 | 5.827 |

| 3/8 | .376 | .397 | .478 | .414 | 1-1/2 | 6.625 | 7.650 | 6.008 | 6.345 |

| 25/64 | .408 | .431 | .519 | .450 | 1-9/16 | 7.189 | 8.301 | 6.519 | 6.885 |

| 13/32 | .441 | .466 | .561 | .486 | 1-5/8 | 7.775 | 8.978 | 7.051 | 7.446 |

| 27/64 | .475 | .502 | .605 | .524 | 1-11/16 | 8.385 | 9.682 | 7.604 | 8.030 |

| 7/16 | .511 | .540 | .651 | .564 | 1-3/4 | 9.018 | 10.41 | 8.178 | 8.634 |

| 29/64 | .548 | .579 | .698 | .604 | 1-13/16 | 9.673 | 11.17 | 8.773 | 9.265 |

| 15/32 | .587 | .620 | .747 | .647 | 1-7/8 | 10.35 | 11.95 | 9.388 | 9.911 |

| 31/64 | .627 | .662 | .798 | .692 | 1-15/16 | 11.05 | 12.76 | 10.02 | 10.58 |

| 1/2 | .668 | .705 | .850 | .736 | 2 | 11.78 | 13.60 | 10.68 | 11.28 |

| 33/64 | .710 | .750 | .904 | .783 | 2-1/16 | 12.53 | 14.46 | 11.36 | 11.99 |

| 17/32 | .754 | .796 | .960 | .831 | 2-1/8 | 13.30 | 15.35 | 12.06 | 12.73 |

| 35/64 | .799 | .844 | 1.017 | .881 | 2-3/16 | 14.09 | 16.27 | 12.78 | 13.49 |

| 9/16 | .845 | .892 | 1.076 | .932 | 2-1/4 | 14.91 | 17.21 | 13.52 | 14.27 |

| 37/64 | .893 | .943 | 1.136 | .985 | 2-5/16 | 15.75 | 18.18 | 14.28 | 15.08 |

| 19/32 | .941 | .994 | 1.199 | 1.038 | 2-3/8 | 16.61 | 19.18 | 15.06 | 15.91 |

| 39/64 | .992 | 1.048 | 1.263 | 1.094 | 2-7/16 | 17.49 | 20.20 | 15.87 | 16.75 |

| 5/8 | 1.043 | 1.102 | 1.328 | 1.150 | 2-1/2 | 18.40 | 21.25 | 16.69 | 17.62 |

| 41/64 | 1.096 | 1.207 | 1.395 | 1.209 | 2-9/16 | 19.34 | 22.33 | 17.53 | 18.52 |

| 21/32 | 1.150 | 1.214 | 1.464 | 1.268 | 2-5/8 | 20.29 | 23.43 | 18.40 | 19.43 |

| 43/64 | 1.205 | 1.272 | 1.535 | 1.329 | 2-11/16 | 21.27 | 24.56 | 19.29 | 20.37 |

| SIZE IN INCHES | HEXAGON | SQUARE | ROUND | OCTAGON | SIZE IN INCHES | SQUARE | ROUND | OCTAGON |

| 2-3/4 | 22.27 | 25.71 | 20.19 | 21.33 | 6 | 122.4 | 96.13 | 101.5 |

| 2-3/16 | 23.29 | 26.90 | 21.12 | 22.31 | 6-1/16 | 125.0 | 98.15 | 103.6 |

| 2-7/8 | 24.34 | 28.10 | 22.07 | 23.31 | 6-1/8 | 127.6 | 100.2 | 105.8 |

| 2-5/16 | 25.41 | 29.34 | 23.04 | 24.33 | 6-3/16 | 130.2 | 102.2 | 108.0 |

| 3 | 26.50 | 30.60 | 24.03 | 25.38 | 6-1/4 | 132.8 | 104.3 | 110.2 |

| 3-1/16 | 27.62 | 31.89 | 25.05 | 26.45 | 6-5/16 | 135.5 | 106.4 | 112.4 |

| 3-1/8 | 28.76 | 33.20 | 26.08 | 27.54 | 6-3/8 | 138.2 | 108.5 | 114.6 |

| 3-3/16 | 29.92 | 34.55 | 27.13 | 28.65 | 6-7/16 | 140.9 | 110.7 | 116.9 |

| 3-1/4 | 35.91 | 28.21 | 29.79 | 6-1/2 | 143.7 | 112.8 | 119.1 | |

| 3-5/16 | 37.21 | 29.30 | 30.94 | 6-9/16 | 146.4 | 115.0 | 121.4 | |

| 3-3/8 | 38.73 | 30.42 | 32.12 | 6-5/8 | 149.2 | 117.2 | 123.8 | |

| 3-7/16 | 40.18 | 31.55 | 33.32 | 6-11/16 | 152.1 | 119.4 | 126.1 | |

| 3-1/2 | 41.6 | 32.71 | 34.54 | 6-3/4 | 154.9 | 121.7 | 128.5 | |

| 3-9/16 | 43.15 | 33.90 | 35.79 | 6-13/16 | 157.8 | 123.9 | 130.9 | |

| 3-5/8 | 44.68 | 35.09 | 37.07 | 6-7/8 | 160.7 | 126.2 | 133.3 | |

| 3-1/16 | 46.23 | 36.31 | 38.34 | 6-15/16 | 163.6 | 128.5 | 135.7 | |

| 3-3/4 | 47.81 | 37.55 | 39.65 | 7 | 166.6 | 130.9 | 138.2 | |

| 3-3/16 | 49.42 | 38.81 | 40.99 | 7-1/16 | 169.6 | 133.2 | 140.7 | |

| 3-7/8 | 51.05 | 40.10 | 42.34 | 7-1/8 | 172.6 | 135.6 | 143.2 | |

| 3-5/16 | 52.71 | 41.40 | 43.72 | 7-3/16 | 175.6 | 138.0 | 145.7 | |

| 4 | 54.40 | 42.73 | 45.12 | 7-1/4 | 178.7 | 140.4 | 148.2 | |

| 4-1/16 | 56.11 | 44.07 | 46.54 | 7-5/16 | 181.8 | 142.8 | 150.8 | |

| 4-1/8 | 57.85 | 45.44 | 47.98 | 7-3/8 | 184.9 | 145.2 | 153.4 | |

| 4-3/16 | 59.62 | 46.83 | 49.45 | 7-7/16 | 188.1 | 147.7 | 156.0 | |

| 4-1/4 | 61.41 | 48.23 | 50.93 | 7-1/2 | 191.3 | 150.2 | 158.6 | |

| 4-5/16 | 63.23 | 49.66 | 52.44 | 7-5/8 | 197.7 | 155.3 | 164.0 | |

| 4-3/8 | 65.08 | 51.11 | 53.98 | 7-3/4 | 204.2 | 160.4 | 169.4 | |

| 4-7/16 | 66.95 | 52.58 | 55.53 | 7-7/8 | 210.9 | 165.6 | 174.9 | |

| 4-1/2 | 68.85 | 54.08 | 57.10 | 8 | 217.6 | 170.9 | 180.5 | |

| 4-9/16 | 70.78 | 55.59 | 58.70 | 8-1/4 | 230.9 | 181.8 | 192.0 | |

| 4-5/8 | 72.73 | 57.12 | 60.32 | 8-1/2 | 245.7 | 192.9 | 203.8 | |

| 4-1/16 | 74.71 | 58.68 | 61.96 | 8-3/4 | 259.6 | 204.4 | 215.8 | |

| 4-3/4 | 76.71 | 60.25 | 63.63 | 9 | 275.4 | 216.3 | 228.4 | |

| 4-3/16 | 78.75 | 61.85 | 65.32 | 10 | 340.0 | 267.0 | 282.0 | |

| 4-7/8 | 80.80 | 63.46 | 67.02 | 11 | 411.4 | 323.1 | 341.2 | |

| 4-5/16 | 82.89 | 65.10 | 68.75 | 12 | 489.6 | 384.4 | 406.1 | |

| 5 | 85.00 | 66.76 | 70.50 | 13 | 575 | 451 | 476 | |

| 5-1/16 | 87.14 | 68.44 | 72.27 | 14 | 666 | 523 | 552 | |

| 5-1/8 | 89.30 | 70.14 | 74.07 | 15 | 765 | 601 | 634 | |

| 5-3/16 | 91.50 | 71.86 | 75.89 | 16 | 871 | 684 | 721 | |

| 5-1/4 | 93.71 | 73.60 | 77.72 | 17 | 982 | 772 | 814 | |

| 5-5/16 | 95.96 | 75.36 | 79.59 | 18 | 1102 | 865 | 912 | |

| 5-3/8 | 98.23 | 77.15 | 81.47 | 19 | 1227 | 964 | 1017 | |

| 5-7/16 | 100.5 | 78.95 | 83.38 | 20 | 1360 | 1068 | 1127 | |

| 5-1/2 | 102.9 | 80.78 | 85.30 | 21 | 1499 | 1177 | 1242 | |

| 5-9/16 | 105.2 | 82.62 | 87.25 | 22 | 1645 | 1292 | 1363 | |

| 5-5/8 | 107.6 | 84.49 | 89.23 | 23 | 1798 | 1412 | 1490 | |

| 5-1/16 | 110.0 | 86.38 | 91.22 | 24 | 1958 | 1538 | 1622 | |

| 5-3/4 | 112.4 | 88.29 | 9323 | 25 | 2125 | 1669 | 1760 | |

| 5-3/16 | 114.9 | 90.22 | 95.27 | 26 | 2298 | 1805 | 1904 | |

| 5-7/8 | 117.4 | 92.17 | 97.33 | 27 | 2478 | 1946 | 2053 | |

| 5-5/16 | 119.9 | 94.14 | 99.41 | 28 | 2665 | 2093 | 2208 |

Types Of F12 Cr-Mo A182 Bar:

-

Chrome Moly F12 Square Bar

-

Alloy Steel F12 Hexagonal Bar

-

Chrome Moly F12 Threaded Bar

-

Alloy Steel F12 Threaded Bar

-

ASTM A182 F12 Alloy Steel Bright Bar

-

F12 Alloy Steel Bright Bar

-

F12 Alloy Steel Hexagonal Bar

-

Alloy Steel F12 Hex Bar

-

ASTM A182 F12 Alloy Steel Hex Bar

-

Alloy Steel F12 Square Bar

-

F12 Alloy Steel Square Bars

-

Alloy Steel F12 Bright Bar

-

Alloy Steel F12 Square Bar

-

F12 Alloy Steel Square Bar

-

Alloy Steel F12 Bright Bar

-

F12 Chrome Moly Bright Bar

-

F12 Chrome Moly Hex Bar

-

Alloy Steel F12 Bright Bar

-

ASTM A182 F12 Alloy Steel Square Bars

-

ASTM A182 F12 Alloy Steel Threaded Bar

-

Alloy Steel F12 Polished Bar

-

ASTM A182 F12 Alloy Steel Flat Bars

-

ASTM A182 F12 Alloy Steel Polished Bar

-

Chrome Moly F12 Rectangular Bar

-

F12 Alloy Steel Threaded Bar

-

F12 Alloy Steel F12 Rectangular Bar

-

Alloy Steel F12 Rectangular Bars

-

F12 Alloy Steel Polished Bar

-

F12 Alloy Steel Flat Bars

-

F12 Alloy Steel Rectangular Bars

-

Alloy Steel F12 Rectangular Bar

-

ASTM A182 F12 Alloy Steel Rectangular Bar

-

Alloy Steel F12 Flat Bars

-

F12 Alloy Steel Threaded Bars

-

Alloy Steel F12 Polished Bars

-

F12 Alloy Steel Flat Bars

-

F12 Alloy Steel Polished Bars

-

Chrome Moly F12 Flat Bars

-

F12 Chrome Moly Polished Bar

-

Alloy Steel F12 Flat Bar

-

Alloy Steel F12 Threaded Bar

Our Products

Our Latest Blogs

A Complete Guide to Duplex and Super Duplex Steel Grades

Compared to older stainless steels, duplex stainless steel grades and super duplex stainless steel grades offer excellent strength and corrosion resistance in demanding industrial settings. These high-performance alloys are meant to withstand demanding environmental...

Related Products

Send Us Message

Got a question? We'd love to hear from you. Send us a message & we'll respond as soon as possible.