Alloy Steel Products

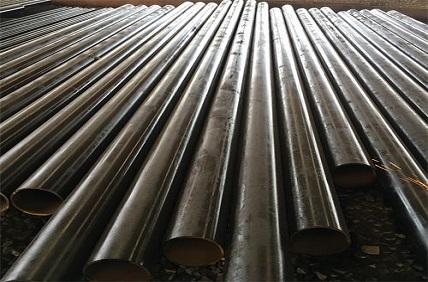

ASTM A335 Alloy Steel P9 Seamless Pipes Supplier & Manufacturer

Alloy Steel P9 Seamless Pipe Table of Content

- Product Specifications – Alloy Steel P9 Seamless Pipes

- Material Details – Alloy Steel P9 Seamless Pipes

- Chemical Composition of Alloy Steel P9 Seamless Pipes

- Mechanical Properties of Alloy Steel P9 Seamless Pipes

- Alloy Steel P9 Seamless Pipes Equivalent Grades

- Alloy Steel P9 Seamless Pipes Outside Diameter

- ASTM A335 Grade P9 Round Pipe Sizes And Schedules

- Grade P9 Fabricated Piping Wall thickness

- Weight of ASTM A335 Gr P9 seamless pipes:

- Alloy Steel P9 Seamless Pipes Types

- Certifications & Quality Assurance

- Applications of Alloy Steel P9 Seamless Pipes

- Product Availability & Delivery

- Alloy Steel P9 Seamless Pipes Price Per KG in India

- Why Choose Lakshya Steel For Alloy Steel P9 Seamless Pipes

- FAQ’s Of Alloy Steel P9 Seamless Pipes

Supported by 25+ years of industry experience we supply Alloy Steel P9 seamless pipes in an array of sizes, wall thicknesses and finishes with customization options including fixed length special coatings and end-preparation. All pipes are produced in accordance with ASTM A335 standards and are delivered with Mill Test Certificates (EN 10204 3.1/3.2), third-party inspection support (SGS, TUV, BV, DNV) and full detectability.

With ready stock quick delivery, cost effective pricing and a customer centric approach, Lakshay Steel stands as your trusted global partner for Alloy Steel Seamless Pipes offering excellent quality and technical support from inquiry to dispatch.

Product Specifications – Alloy Steel P9 Seamless Pipes

Lakshay Steel distributes ASTM A335 Alloy Steel P9 Seamless Pipes with accuracy designed requirements to match the essential demands of high pressure and high temperature environments. These pipes are largely used in boilers, heat exchangers, power plants and petrochemical industries due to their excellent strength, oxidation endurance and durability.

We offer both standard and custom specifications guaranteeing seamless integration with your project need

Key Product Specifications

| Specification Category | Details |

| Standard | ASTM A335 / ASME SA335 – Grade P9 |

| Size Range | ½” NB to 24” NB (Nominal Bore) |

| Schedules Available | SCH 40, SCH 80, SCH 160, XXS, Custom |

| Pipe Lengths | Single Random (SRL), Double Random (DRL), Cut-to-Length |

| Pipe Ends | Plain End (PE), Beveled End (BE), Threaded End (TE) |

| Pipe Forms | Seamless Round Pipes, U-Bent Pipes, Fabricated Spools (on request) |

| Surface Finish | Black Painted, Bare, Varnished, Anti-Corrosive Coated, FBE Coated |

| Manufacturing Process | Hot Finished or Cold Drawn |

| Dimensional Standards | ANSI B36.10, EN, DIN, BS, and custom as per client specs |

| Compliance | NACE MR0175, IBR, PED, ISO, CE Marking |

Looking for specific sizes or project-based solutions? Lakshay Steel offers immediate availability and responsive support for both small and bulk orders.

Material Details – Alloy Steel P9 Seamless Pipes

Alloy Steel P9 Seamless Pipes are produced using a chromium molybdenum alloy that offers excellent performance under high pressure and high-temperature environments. At Lakshya Steel we guarantee each pipe meets stringent metallurgical standards, offering excellent mechanical strength, corrosion resistance, and long service life.

Below are the critical material properties that define the reliability and performance of ASTM A335 P9 seamless pipes:

Chemical Composition of Alloy Steel P9 Seamless Pipes

| Carbon (C) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Silicon (Si) | Chromium (Cr) | Molybdenum (Mo) |

| Max 0.15 | 0.30 – 0.60 | Max 0.025 | Max 0.025 | 0.50 – 1.00 | 8.00 – 10.00 | 0.90 – 1.10 |

Note: Chemical values are controlled for consistent weldability and performance under thermal stress.

Mechanical Properties of Alloy Steel P9 Seamless Pipes

| Tensile Strength | Yield Strength (0.2% offset) | Elongation | Hardness (HBW) | Impact Strength |

| ≥ 415 MPa (60,000 psi) | ≥ 205 MPa (30,000 psi) | ≥ 30% | ≤ 163 HB | As per application/standard |

Equivalent Standard For Alloy steel P9 Seamless Pipes:

| GRADE | UNS | EN | BS | DIN | GOST | AFNOR | WNR |

| P9 | S50400 | – | – | – | – | – | 1.4903 |

Alloy Steel P9 Seamless Pipes Outside Diameter :

| Hot rolled | Outside Diameter, mm | Tolerance, mm |

| OD≤101.6 | +0.4/-0.8 | |

| 101.6<OD≤190.5 | +0.4/-1.2 | |

| 190.5<OD≤228.6 | +0.4/-1.6 | |

| Cold Drawn | Outside Diameter, mm | Tolerance, mm |

| OD<25.4 | ±0.10 | |

| 25.4≤OD≤38.1 | ±0.15 | |

| 38.1<OD<50.8 | ±0.20 | |

| 50.8≤OD<63.5 | ±0.25 | |

| 63.5≤OD<76.2 | ±0.30 | |

| 76.2≤OD≤101.6 | ±0.38 | |

| 101.6<OD≤190.5 | +0.38/-0.64 | |

| 190.5<OD≤228.6 | +0.38/-1.14 |

ASTM A335 Grade P9 Round Pipe Sizes And Schedules:

| Hot rolled | Outside Diameter, mm | Tolerance, mm |

| OD≤101.6 | +0.4/-0.8 | |

| 101.6<OD≤190.5 | +0.4/-1.2 | |

| 190.5<OD≤228.6 | +0.4/-1.6 | |

| Cold Drawn | Outside Diameter, mm | Tolerance, mm |

| OD<25.4 | ±0.10 | |

| 25.4≤OD≤38.1 | ±0.15 | |

| 38.1<OD<50.8 | ±0.20 | |

| 50.8≤OD<63.5 | ±0.25 | |

| 63.5≤OD<76.2 | ±0.30 | |

| 76.2≤OD≤101.6 | ±0.38 | |

| 101.6<OD≤190.5 | +0.38/-0.64 | |

| 190.5<OD≤228.6 | +0.38/-1.14 |

Grade P9 Fabricated Piping Wall thickness:

| Hot rolled | Outside Diameter, mm | Tolerance, % |

| OD≤101.6, WT≤2.4 | +40/-0 | |

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | |

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 | |

| OD≤101.6, WT>4.6 | +28/-0 | |

| OD>101.6, 2.4<WT≤3.8 | +35/-0 | |

| OD>101.6, 3.8<WT≤4.6 | +33/-0 | |

| OD>101.6, WT>4.6 | +28/-0 | |

| Cold Drawn | Outside Diameter, mm | Tolerance, % |

| OD≤38.1 | +20/-0 | |

| OD>38.1 | +22/-0 |

ASTM A335 Grade P9 Round Pipe Sizes And Schedules:

| O.D. x Thickness(mm) | O.D x Thickness(mm) | O.D x Thickness(mm) |

| 38.1 x 3.2 | 57.0 x 4.9 | 76.2 x 4.0 |

| 38.1 x 4.0 | 57.0 x 6.3 | 76.2 x 5.0 |

| 38.1 x 6.3 | 57.0 x 7.9 | 76.2 x 6.3 |

| 42.4 x 3.2 | 60.3 x 3.2 | 82.5 x 4.5 |

| 42.4 x 4.0 | 60.3 x 3.6 | 88.9 x 3.2 |

| 44.5 x 3.2 | 60.3 x 5.0 | 88.9 x 3.6 |

| 44.5 x 6.3 | 63.5 x 3.2 | 88.9 x 4.0 |

| 48.3 x 3.2 | 63.5 x 3.6 | 101.6 x 3.6 |

| 48.3 x 3.6 | 63.5 x 4.0 | 101.6 x 4.5 |

| 50.8 x 4.5 | 63.5 x 6.3 | 101.6 x 6.3 |

| 51.0 x 3.2 | 63.5 x 7.9 | 114.3 x 3.6 |

| 51.0 x 3.6 | 70.0 x 3.2 | 114.3 x 5.0 |

| 51.0 x 6.3 | 70.0 x 3.6 | 139.7 x 4.0 |

| 57.0 x 3.2 | 70.0 x 6.3 | 139.7 x 5.0 |

| 57.0 x 3.6 | 76.2 x 3.6 | 139.7 x 6.3 |

| NB | Size | OD | 40S | 5S | 10S | S10 | S20 | S40 | S60 | XS/80S | S80 | S100 | S120 | S140 | S160 | XXS |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | ||

| 1/8 | 10.29 | 1.2 | 1.73 | 2.41 | ||||||||||||

| 1/4 | 13.72 | 1.7 | 2.24 | 3.02 | ||||||||||||

| 3/8 | 17.15 | 1.7 | 2.31 | 3.2 | ||||||||||||

| 15 | 1/2 | 21.34 | 2.8 | 1.7 | 2.1 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | ||||||

| 20 | 3/4 | 26.67 | 2.9 | 1.7 | 2.1 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | ||||||

| 25 | 1 | 33.4 | 3.4 | 1.7 | 2.8 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | ||||||

| 32 | 1 1/4 | 42.16 | 3.6 | 1.7 | 2.8 | 3.56 | 4.85 | 4.85 | 6.35 | 9.7 | ||||||

| 40 | 1 1/2 | 48.26 | 3.7 | 1.7 | 2.8 | 3.68 | 5.08 | 5.08 | 7.14 | 10.2 | ||||||

| 50 | 2 | 60.33 | 3.9 | 1.7 | 2.8 | 3.91 | 5.54 | 5.54 | 9.74 | 11.1 | ||||||

| 65 | 2 1/2 | 73.03 | 5.2 | 2.1 | 3.1 | 5.16 | 7.01 | 7.01 | 9.53 | 14 | ||||||

| 80 | 3 | 88.9 | 5.5 | 2.1 | 3.1 | 5.49 | 7.62 | 7.62 | 11.1 | 15.2 | ||||||

| 90 | 3 1/2 | 101.6 | 5.7 | 2.1 | 3.1 | 5.74 | 8.08 | 8.08 | ||||||||

| 100 | 4 | 114.3 | 6 | 2.1 | 3.1 | 6.02 | 8.56 | 8.56 | 11.1 | 13.5 | 17.1 | |||||

| 125 | 5 | 141.3 | 6.6 | 2.8 | 3.4 | 6.55 | 9.53 | 9.53 | 12.7 | 15.9 | 19.1 | |||||

| 150 | 6 | 168.3 | 7.1 | 2.8 | 3.4 | 7.11 | 10.97 | 11 | 14.3 | 18.3 | 22 | |||||

| 200 | 8 | 219.1 | 8.2 | 2.8 | 3.8 | 6.4 | 8.18 | 10.3 | 12.7 | 12.7 | 15.1 | 19.3 | 20.6 | 23 | 22.2 | |

| 250 | 10 | 273.1 | 9.3 | 3.4 | 4.2 | 6.4 | 9.27 | 12.7 | 12.7 | 15.1 | 19.3 | 21.4 | 25.4 | 28.6 | 25.4 | |

| 300 | 12 | 323.9 | 9.5 | 4 | 4.6 | 6.4 | 10.3 | 14.3 | 12.7 | 17.5 | 21.4 | 25.4 | 28.6 | 33.3 | 25.4 | |

| 350 | 14 | 355.6 | 9.5 | 4 | 4.8 | 6.4 | 7.9 | 11.1 | 15.1 | 12.7 | 19.1 | 23.8 | 27.8 | 31.8 | 35.7 | |

| 400 | 16 | 406.4 | 9.5 | 4.2 | 4.8 | 6.4 | 7.9 | 12.7 | 16.7 | 12.7 | 21.4 | 26.2 | 31 | 36.5 | 40.5 | |

| 450 | 18 | 457.2 | 9.5 | 4.2 | 4.8 | 6.4 | 7.9 | 14.3 | 19.1 | 12.7 | 23.8 | 29.4 | 34.9 | 39.7 | 45.2 | |

| 500 | 20 | 508 | 9.5 | 4.8 | 5.5 | 6.4 | 9.5 | 15.1 | 20.6 | 12.7 | 26.2 | 32.5 | 38.1 | 44.5 | 50 | |

| 550 | 22 | 558.8 | 9.5 | 4.8 | 5.5 | 6.4 | 9.5 | 22.2 | 12.7 | 28.6 | 34.9 | 41.3 | 47.6 | 54 | ||

| 600 | 24 | 609.6 | 9.5 | 5.5 | 6.4 | 6.4 | 9.5 | 17.5 | 24.6 | 12.7 | 31 | 38.9 | 46 | 52.4 | 59.5 | |

| 650 | 26 | 660.4 | 9.5 | 7.9 | 13 | 12.7 | ||||||||||

| 700 | 28 | 711.2 | 9.5 | 7.9 | 13 | 12.7 | ||||||||||

| 750 | 30 | 762 | 9.5 | 6.4 | 7.9 | 7.9 | 13 | 12.7 | ||||||||

| 800 | 32 | 812.8 | 9.5 | 7.9 | 13 | 17.5 | 12.7 | |||||||||

| 850 | 34 | 863.6 | 9.5 | 7.9 | 13 | 17.5 | 12.7 | |||||||||

| 900 | 36 | 914.4 | 9.5 | 7.9 | 13 | 19.1 | 12.7 |

Weight Of ASTM A335 gr P9 seamless pipes:

| Size NPS | Pipe O.D. | Wall Thickness | Pipe I.D. | Weight per Foot | Standard to XXHY | Schedule

Pipe # |

Section Modulus | Gallon Capacity Per Linear Foot |

| 1/2 | 0.84 | 0.109 | 0.622 | 0.85 | STD | 40 | .0407 | .0158 |

| 0.147 | 0.546 | 1.09 | XHY | 80 | .0478 | .0122 | ||

| 0.188 | 0.464 | 1.31 | 160 | .0528 | .0088 | |||

| 0.294 | 0.252 | 1.72 | XXHY | .0577 | .0026 | |||

| 3/4 | 1.05 | 0.113 | 0.824 | 1.13 | STD | 40 | .0705 | .0277 |

| 0.154 | 0.742 | 1.48 | XHY | 80 | .0853 | .0225 | ||

| 0.219 | 0.612 | 1.95 | 160 | .1006 | .0153 | |||

| 0.308 | 0.434 | 2.44 | XXHY | .1103 | .0077 | |||

| 1 | 1.315 | 0.133 | 1.049 | 1.68 | STD | 40 | .1328 | .0449 |

| 0.179 | 0.957 | 2.17 | XHY | 80 | .1606 | .0374 | ||

| 0.250 | 0.815 | 2.85 | 160 | .1904 | .0271 | |||

| 0.358 | 0.599 | 3.66 | XXHY | .2136 | .0146 | |||

| 1 1/4 | 1.66 | 0.140 | 1.380 | 2.27 | STD | 40 | .2346 | .0777 |

| 0.191 | 1.278 | 3.00 | XHY | 80 | .2913 | .0666 | ||

| 0.250 | 1.160 | 3.77 | 160 | .3421 | .0549 | |||

| 0.382 | 0.896 | 5.22 | .4110 | .0328 | ||||

| 1 1/2 | 1.90 | 0.145 | 1.610 | 2.72 | STD | 40 | .3262 | .1058 |

| 0.200 | 1.500 | 3.63 | XHY | 80 | .4118 | .0918 | ||

| 0.281 | 1.338 | 4.86 | 160 | .5079 | .0730 | |||

| 0.400 | 1.100 | 6.41 | .5977 | .0494 | ||||

| 2 | 2.375 | 0.109 | 2.157 | 2.64 | 10 | .4205 | .1898 | |

| 0.154 | 2.067 | 3.66 | STD | 40 | .5606 | .1743 | ||

| 0.218 | 1.939 | 5.03 | XHY | 80 | .7309 | .1534 | ||

| 0.250 | 1.875 | 5.68 | .8045 | .1434 | ||||

| 0.281 | 1.813 | 6.29 | .8666 | .1344 | ||||

| 0.344 | 1.687 | 7.47 | 160 | .9806 | .1161 | |||

| 0.436 | 1.503 | 9.04 | XXHY | 1.1043 | .0922 | |||

| 2 1/2 | 2.875 | 0.120 | 2.635 | 3.53 | 10 | .6870 | .2833 | |

| 0.203 | 2.469 | 5.80 | STD. | 40 | 1.0640 | .2487 | ||

| 0.216 | 2.443 | 6.14 | 1.1169 | .2435 | ||||

| 0.250 | 2.375 | 7.02 | 1.2468 | .2301 | ||||

| 0.276 | 2.323 | 7.67 | XHY | 80 | 1.3386 | .2202 | ||

| 0.375 | 2.125 | 10.02 | 160 | 1.6371 | .1842 | |||

| 0.552 | 1.771 | 13.71 | XXXHY | 1.9971 | .1280 | |||

| 3 | 3.50 | 0.120 | 3.260 | 4.34 | 1.0411 | .4336 | ||

| 0.156 | 3.188 | 5.58 | 1.3122 | .4147 | ||||

| 0.172 | 3.156 | 6.12 | 1.4265 | .4064 | ||||

| 0.188 | 3.124 | 6.66 | 1.5342 | .3984 | ||||

| 0.216 | 3.068 | 7.58 | STD. | 40 | 1.7241 | .3840 | ||

| 0.250 | 3.000 | 8.69 | 1.9372 | .3672 | ||||

| 0.281 | 2.938 | 9.67 | 2.1207 | .3521 | ||||

| 0.300 | 2.900 | 10.26 | XHY | 80 | 2.2253 | .3431 | ||

| 0.438 | 2.624 | 14.34 | 160 | 2.8774 | .2811 | |||

| 0.600 | 2.300 | 18.6 | XXHY | 3.4243 | .2158 | |||

| 3 1/2 | 4.0 | 0.120 | 3.760 | 4.98 | 10 | 1.3776 | .5768 | |

| 0.226 | 3.548 | 9.12 | STD. | 140 | 2.3939 | .5136 | ||

| 0.250 | 3.500 | 10.02 | 2.6001 | .4998 | ||||

| 0.281 | 3.438 | 11.17 | 2.8562 | .4821 | ||||

| 0.318 | 3.364 | 12.52 | XHY | 80 | 3.1400 | .4617 | ||

| 0.636 | 2..728 | 22.87 | XXHY | 4.8795 | .3085 | |||

| 4 | 4.5 | 0.120 | 4.260 | 5.62 | 10 | 1.7612 | .7404 | |

| 0.156 | 4.188 | 7.24 | 2.2354 | .7156 | ||||

| 0.188 | 4.124 | 8.67 | 2.6296 | .6942 | ||||

| 0.203 | 4.094 | 9.32 | 2.8173 | .6838 | ||||

| 0.219 | 4.062 | 10.02 | 3.0184 | .6725 | ||||

| 0.237 | 4.026 | 10.80 | STD. | 40 | 3.2145 | .6613 | ||

| 0.250 | 4.000 | 11.36 | 3.3611 | .6528 | ||||

| 0.281 | 3.938 | 12.67 | 60 | 3.7021 | .6326 | |||

| 0.312 | 3.876 | 13.97 | 4.0273 | .6126 | ||||

| 0.337 | 3.826 | 15.00 | XHY | 80 | 4.2713 | .5972 | ||

| 0.438 | 3.624 | 19.02 | 120 | 5.1790 | .5361 | |||

| 0.531 | 3.438 | 22.53 | 160 | 5.8997 | .4822 | |||

| 0.674 | 3.152 | 27.57 | XXHY | 6.7927 | .4054 | |||

| 5 | 5.563 | 0.188 | 5.187 | 10.80 | 4.1161 | 1.0979 | ||

| 0.219 | 5.125 | 12.51 | 4.7279 | 1.0716 | ||||

| 0.258 | 5.047 | 14.63 | STD. | 40 | 5.4500 | 1.0391 | ||

| 0.281 | 5.001 | 15.87 | 5.8644 | 1.0204 | ||||

| 0.312 | 4.939 | 17.51 | 6.4074 | .99647 | ||||

| 0.344 | 4.875 | 19.19 | 6.9358 | .9696 | ||||

| 0.375 | 4.813 | 20.80 | XHY | 80 | 7.4300 | .9449 | ||

| 0.500 | 4.563 | 27.06 | 120 | 9.2534 | .8495 | |||

| 0.625 | 4.313 | 32.99 | 160 | 10.7976 | .7590 | |||

| 0.750 | 4.063 | 38.59 | XXHY | 12.0954 | .6734 | |||

| 6 | 6.625 | 0.109 | 6.407 | 7.59 | 5 | 3.5769 | 1.6748 | |

| 0.134 | 6.357 | 9.30 | 10 | 4.3475 | 1.6488 | |||

| 0.156 | 6.313 | 10.79 | 5.0107 | 1.6260 | ||||

| 0.188 | 6.249 | 12.94 | 5.9351 | 1.5937 | ||||

| 0.203 | 6.219 | 13.94 | 6.3804 | 1.5780 | ||||

| 0.219 | 6.187 | 15.00 | 6.8261 | 1.5620 | ||||

| 0.250 | 6.125 | 17.04 | 7.6905 | 1.5306 | ||||

| 0.280 | 6.065 | 18.99 | STD. | 40 | 8.4958 | 1.5008 | ||

| 0.312 | 6.001 | 21.06 | 9.3416 | 1.4688 | ||||

| 0.344 | 5.937 | 23.10 | 10.111 | 1.4391 | ||||

| 0.375 | 5.875 | 25.05 | 10.893 | 1.4082 | ||||

| 0.432 | 5.761 | 28.60 | XHY | 80 | 12.224 | 1.3541 | ||

| 0.500 | 5.625 | 32.74 | 13.711 | 1.2909 | ||||

| 0.562 | 5.501 | 36.43 | 120 | 14.9806 | 1.2346 | |||

| 0.625 | 5.375 | 40.09 | 16.1821 | 1.1787 | ||||

| 0.719 | 5.187 | 45.39 | 160 | 17.8243 | 1.0977 | |||

| 0.864 | 4.897 | 53.21 | XXHY | 20.025 | .9784 | |||

| 1.000 | 4.625 | 60.13 | 21.7719 | .8727 | ||||

| 1.125 | 4.375 | 66.14 | 23.1237 | .7809 |

Types Of Alloy steel P9 Seamless Pipes :

| Alloy Steel P9 Seamless Pipes | P9 Alloy Steel A335 Pipe |

| ASTM A335 grade P9 Seamless Pipes | ASTM A335 P9 Alloy Steel Seamless Pipe |

| High Pressure P9 Boiler Pipe | ASME SA335 P9 Alloy Steel Rectangular Pipe |

| Alloy Steel P9 Seamless Pipes | Alloy Steel Gr P9 Heater Pipe |

| ASME SA 213 Alloy Steel P9 Seamless Pipe | IBR Alloy Steel P9 Seamless Pipes |

| Alloy Steel P9 Custom Pipes | ASME SA / ASTM A335 P9 Seamless Pipes |

| Alloy Steel Grade P9 Round Pipe | ASME SA335 P9 Seamless Pipes Suppliers |

| Alloy A335 P9 Seamless Square Pipe | ASME SA335 P9 Alloy Steel Seamless Pipe |

| AISI P9 ERW Pipe | ASTM A335 P9 Seamless Pipes |

| ASTM A335 P9 Boiler Pipe | Tubo A335 P9 Seamless Pipe |

| ASME SA335 P9 Seamless Alloy Pipe | ASME SA335 P9 Seamless Pipes |

| ASME SA335 P9 Material | ASME SA335 Grade P9 Seamless Pipe |

| ASME SA335 Grade P9 Seamless Pipe | ASME SA335 Gr P9 Seamless Pipe |

| ASME SA335 P9 Thermal Conductivity | Astm A335 Grade P9 Seamless Pipe |

| ASME SA335 Gr P9 Seamless Pipe | ASME SA335 P9 Material |

| Astm A335 Gr P9 Seamless Pipe | ASME SA335 P9 Seamless Pipe |

| Astm A335 P9 Seamless Pipe | ASME SA335 P9 Piping |

| ASME SA335 P9 Seamless Pipe | ASTM A335 P9 Steel |

| Astm A335 P9 Seamless Pipe | ASTM A335 P9 Seamless Pipe Material |

| ASTM A335 P9 Piping | ASTM A335 P9 Seamless Pipes |

Certifications & Quality Assurance

We follow a comprehensive quality management system that includes:

- Mill Test Certificates (MTC):

All pipes come with EN 10204 3.1/3.2 MTCs, ensuring full traceability, chemical/mechanical compliance, and ASTM A335 P9 standards. - Quality Certifications:

We are certified to ISO 9001, ISO 14001, ISO 45001, PED 2014/68/EU and IBR for quality, safety and regulatory adherence - Third-Party Inspections:

TPI by reputed agencies like BV, TUV, SGS, DNV and Lloyd’s Register can be arranged on request for added assurance.

Applications of Alloy Steel P9 Seamless Pipes

Key Applications:

- Power Plants: Superheaters, reheaters, headers and boiler tubes

- Petrochemical & Refineries: Heat exchangers, catalytic reformers, process piping

- Oil & Gas: High-pressure transmission lines, offshore/onshore rigs

- Thermal & Nuclear Plants: Steam lines, feedwater systems

- Industrial Boilers & Furnaces: Pressure vessels, combustion chambers

- Aerospace & Defense: Structural components requiring thermal stability

Product Availability & Delivery

In-Stock Availability:

- Sizes: ½” NB to 24” NB

- Schedules: SCH 40, SCH 80, SCH 160, XXS & custom wall thicknesses

- Lengths: Single Random, Double Random, and Cut-to-Length

- Ends: Plain End (PE), Beveled End (BE), Threaded End (TE)

- Forms: Straight pipes, U-bends, and fabricated spools (on request

Customization Options:

- Cut-to-length fabrication

- Bending and shaping

- Surface coatings (FBE, anti-corrosive, painted)

- Markings and packaging as per customer specs

- Export-grade packaging (wooden boxes, HDPE wraps, end caps)

Minimum Order Quantity (MOQ):

- Stock Sizes: As low as 1 piece

- Bulk Orders: Attractive pricing and dedicated fulfillment support

Alloy Steel P9 Seamless Pipes Price Per KG in India

- Pipe Size & Wall Thickness

- Quantity Ordered (MOQ or Bulk)

- Surface Finish & Coating Requirements

- Testing & Certification (MTC, TPI, etc.)

- Customizations like Cut-to-Length, Bending, or Marking

Why Choose Lakshya Steel For Alloy Steel P9 Seamless Pipes

- Proven Industry Experience

With 25+ years in alloy steel manufacturing, Lakshya Steel offers expert knowledge and tailored solutions for demanding, high-pressure applications. - Certified Quality & Compliance

Our P5 Seamless Pipes meet ASTM A335 / ASME SA335 standards and come with EN 10204 3.1/3.2 MTCs, ISO certifications, PED/IBR/NACE approvals, and third-party inspections (TUV, SGS, BV, DNV). - Custom Solutions & Fast Delivery

We offer cut-to-length, custom sizing, and finish options — backed by a strong inventory and global logistics for fast, reliable dispatch. - Trusted Worldwide

Supplying to 50+ countries, we serve EPCs, Fortune 500s, and government agencies — combining global reach with local support. - Fair Pricing, Clear Quotes

We offer competitive pricing, bulk order discounts and transparent quotations to support your budget and timeline. - Reliability You Can Count On

Known for zero-defect delivery and long-term partnerships, clients choose Lakshya Steel for consistent quality and dependable service.

FAQ’s Of Alloy Steel P9 Seamless Pipes

What is P9 piping material?

What is ASME P9 material?

ASME P9 material refers to alloy steel grade P9 as specified under ASME SA335. It is a Cr-Mo alloy designed for high-temperature service in power plants and petrochemical industries, offering excellent heat resistance and mechanical strength.

What is the difference between P9 and P91 material?

What is the material grade of MS seamless pipe?

What are the 3 grades of steel pipe?

Our Products

Our Latest Blogs

Carbon Steel vs Stainless Steel: Key Differences You Need to Know

Picking the right steel for any job in industry is a pretty big deal. Whether you're building huge pipelines, putting up buildings, or making tiny, precise parts, the steel you choose affects how well things work, how long they last, and what they cost. Lots of folks...

What is ERW Pipe and How Are ERW Pipes Made?

When you think about materials that build our world, steel pipes are right up there. They're essential for so many things, from carrying water to supporting buildings. Among the different kinds of steel pipes, ERW pipe – which stands for Electric Resistance Welded...

What is an Alloy? A Complete Guide to Alloy Metal

Ever think about alloys all around you. Strong car wheels for example. Or kitchen tools that don't rust. Yes, alloys are everywhere. But many people do not really know what is an alloy. In this blog, we will discuss everything about alloys. We will talk about what...

Related Products

Send Us Message

Got a question? We'd love to hear from you. Send us a message & we'll respond as soon as possible.