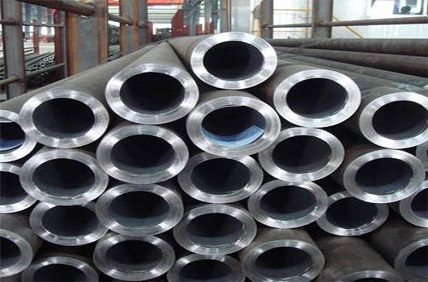

ASTM A335 Alloy Steel P22 Seamless Pipes

Table of Content

- Alloy steel p22 Material Dimensions Standard & Specifications

- Product Specifications – Alloy Steel P22 Seamless Pipes

- Chemical Composition (% by weight) – ASTM A335 / ASME SA335 P22

- Mechanical Properties – Alloy Steel P22

- P22 Material Equivalents

- Alloy Steel P22 Seamless Pipes Outside Diameter

- Wall thickness Grade ASTM A335 P22 Seamless Pipe

- Applications of Alloy steel p22 Seamless Pipes

- FAQ

Alloy Steel P22 Seamless Pipes – Supplier & Manufacturer in India | Lakshya Steel

Being one of the most reputable names in India as a producer and supplier of Alloy Steel P22 Seamless Pipes, which provides high-performance piping solutions to vital sectors all around, Lakshya Steel makes great pride. Designed for use in high-temperature and high-pressure situations like power plants, refineries, petrochemical units, and boiler systems, these seamless alloy pipes manufactured under ASTM A335 / ASME SA335 Grade P22 are developed.

Designed from Chromium-Molybdenum (Cr-Mo) alloy steel, our P22 seamless pipes are perfect for long-term operation under demanding conditions since they have outstanding oxidation resistance, thermal stability, and creep strength. Our pipes guarantee durability, safety, and operating efficiency regardless of the type of application—superheated steam, high-pressure fluids, corrosive gases, or another.

- Being a top Alloy Steel P22 Seamless Pipes supplier in India, Lakshya Steel presents:

- Perfectly sketched seamless pipes with exact measurements

- Broad spectrum of sizes and wall thicknesses at hand

- Custom cut-to–length remedies and surface treatments

- Third-party tests (SGS, TUV, BV) and mill test certificates (MTCs)

- Following worldwide standards: ASTM, ASME, DIN, EN, IBR, and PED

Strongly committed to quality, technical know-how, and prompt delivery, Lakshya Steel helps OEMs, engineers, EPC contractors, and procurement teams all over. Our extensive inventory and export capacity guarantees that we equally handle high industrial demand, small quantity orders, and tight project deadlines.

What is Alloy Steel P22?

Alloy steel p22 Material Dimensions Standard & Specifications

|

Material |

Size (in mm) |

Sch. & Swg. |

Specification |

|

ASTM A335 P22 Seamless Pipes |

15 NB to 300 NB |

Sch. 40s To Sch. XXs (heavier on request) |

ASTM A 335, ASME SA 335 Seamless |

Product Specifications – Alloy Steel P22 Seamless Pipes

Standard Specifications:

| Specification | Details |

| Product Name | Alloy Steel P22 Seamless Pipes |

| Manufacturing Standard | ASTM A335 / ASME SA335 |

| Grade | P22 |

| Type | Seamless |

| Size Range | 1/2” NB to 24” NB (Custom sizes available on request) |

| Wall Thickness (Schedule) | SCH 10 to SCH 160 / XXS |

| Outer Diameter | 21.3 mm – 610 mm |

| Length | Single Random, Double Random & Custom Cut-to-Length |

| End Finish | Plain Ends (PE), Beveled Ends (BE), Threaded Ends (TE) |

| Form | Round, Hydraulic, U-Bend, Straight |

| Surface Finish | Black Painted, Bare, Varnished, or Oiled |

| Production Process | Hot Finished / Cold Drawn |

| Heat Treatment | Normalized and Tempered (N+T) as per standard or client specification |

| Marking & Identification | Standard/Custom marking with heat number, size, grade, and logo |

| Testing | Hydrostatic Test, Ultrasonic Test, Eddy Current, PMI, and Visual Inspection |

Material Details – Alloy Steel P22 Seamless Pipes

Chemical Composition (% by weight) – ASTM A335 / ASME SA335 P22

| Element | Minimum (%) | Maximum (%) |

| Carbon (C) | 0.05 | 0.15 |

| Manganese (Mn) | 0.30 | 0.60 |

| Phosphorus (P) | – | 0.025 |

| Sulfur (S) | – | 0.025 |

| Silicon (Si) | 0.50 | 1.00 |

| Chromium (Cr) | 1.90 | 2.60 |

| Molybdenum (Mo) | 0.87 | 1.13 |

Mechanical Properties – Alloy Steel P22

| Property | Value |

| Tensile Strength | ≥ 415 MPa |

| Yield Strength (0.2% Offset) | ≥ 205 MPa |

| Elongation (%) | ≥ 20% (Longitudinal) |

| Hardness (HBW) | ≤ 163 (Typically, not to exceed) |

| Impact Strength | As per application requirements |

Using premium raw materials, cutting-edge heat treatment techniques, and precise machining, Lakshya Steel guarantees that every P22 seamless pipe is produced to satisfy the most exacting service conditions.

P22 Material Equivalents

Alloy Steel P22 is recognized and used internationally with various equivalent standards:

| Standard | Equivalent Grade | Country/Region | Remarks |

| ASTM | A335 Grade P22 | USA | Seamless ferritic alloy-steel pipe |

| ASME | SA335 Grade P22 | USA | Pressure applications, high-temperature service |

| EN/DIN | 10CrMo9-10 | Europe/Germany | Similar chemical & mechanical properties |

| BS | 620 B | United Kingdom | British equivalent alloy steel grade |

| UNS | K21590 | International | Unified Numbering System designation |

| JIS | G3458 STPA 23 | Japan | Alloy steel pipes for high-temperature service |

ASME SA335 P22 Seamless Pipes Outside Diameter :

| Hot rolled | Outside Diameter, mm | Tolerance, mm |

| OD≤101.6 | +0.4/-0.8 | |

| 101.6<OD≤190.5 | +0.4/-1.2 | |

| 190.5<OD≤228.6 | +0.4/-1.6 | |

| Cold Drawn | Outside Diameter, mm | Tolerance, mm |

| OD<25.4 | ±0.10 | |

| 25.4≤OD≤38.1 | ±0.15 | |

| 38.1<OD<50.8 | ±0.20 | |

| 50.8≤OD<63.5 | ±0.25 | |

| 63.5≤OD<76.2 | ±0.30 | |

| 76.2≤OD≤101.6 | ±0.38 | |

| 101.6<OD≤190.5 | +0.38/-0.64 | |

| 190.5<OD≤228.6 | +0.38/-1.14 |

Wall Thickness Grade Of Alloy Steel P22 Seamless Pipe

| Hot rolled | Outside Diameter, mm | Tolerance, % |

| OD≤101.6, WT≤2.4 | +40/-0 | |

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | |

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 | |

| OD≤101.6, WT>4.6 | +28/-0 | |

| OD>101.6, 2.4<WT≤3.8 | +35/-0 | |

| OD>101.6, 3.8<WT≤4.6 | +33/-0 | |

| OD>101.6, WT>4.6 | +28/-0 | |

| Cold Drawn | Outside Diameter, mm | Tolerance, % |

| OD≤38.1 | +20/-0 | |

| OD>38.1 |

ASME SA335 P22 Steel Pipe Heat Treatment Requirements :

| P5, P9, P11, and P22 Grade | Heat Treatment Type | Normalizing Temperature Range F [C] | Subcritical Annealing or Tempering

Temperature Range F [C] |

| P5 (b,c) | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| Subcritical Anneal (P5c only) | ***** | 1325 – 1375 [715 – 745] | |

| P9 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| P11 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1200 [650] | |

| P22 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| P91 | Normalize and Temper | 1900-1975 [1040 – 1080] | 1350-1470 [730 – 800] |

| Quench and Temper | 1900-1975 [1040 – 1080] | 1350-1470 [730 – 800] |

ASME SA335 Grade P22 Pipe Tensile Requirements :

| Seamless | ||||||

| P-5 | P-9 | P-11 | P-22 | P-91 | ||

| Tensile Strength, min., psi | ||||||

| ksi | 60 | 60 | 60 | 60 | 85 | |

| MPa | 415 | 415 | 415 | 415 | 585 | |

| Yield Strength, min., psi | ||||||

| ksi | 30 | 30 | 30 | 30 | 60 | |

| MPa | 205 | 205 | 205 | 205 | 415 | |

Alloy Steel P22 Pipe Weight Per Meter :

| Size NPS | Pipe O.D. | Wall Thickness | Pipe I.D. | Weight per Foot | Standard to XXHY | Schedule

Pipe # |

Section Modulus | Gallon Capacity Per Linear Foot |

| 1/2 | 0.84 | 0.109 | 0.622 | 0.85 | STD | 40 | .0407 | .0158 |

| 0.147 | 0.546 | 1.09 | XHY | 80 | .0478 | .0122 | ||

| 0.188 | 0.464 | 1.31 | 160 | .0528 | .0088 | |||

| 0.294 | 0.252 | 1.72 | XXHY | .0577 | .0026 | |||

| 3/4 | 1.05 | 0.113 | 0.824 | 1.13 | STD | 40 | .0705 | .0277 |

| 0.154 | 0.742 | 1.48 | XHY | 80 | .0853 | .0225 | ||

| 0.219 | 0.612 | 1.95 | 160 | .1006 | .0153 | |||

| 0.308 | 0.434 | 2.44 | XXHY | .1103 | .0077 | |||

| 1 | 1.315 | 0.133 | 1.049 | 1.68 | STD | 40 | .1328 | .0449 |

| 0.179 | 0.957 | 2.17 | XHY | 80 | .1606 | .0374 | ||

| 0.250 | 0.815 | 2.85 | 160 | .1904 | .0271 | |||

| 0.358 | 0.599 | 3.66 | XXHY | .2136 | .0146 | |||

| 1 1/4 | 1.66 | 0.140 | 1.380 | 2.27 | STD | 40 | .2346 | .0777 |

| 0.191 | 1.278 | 3.00 | XHY | 80 | .2913 | .0666 | ||

| 0.250 | 1.160 | 3.77 | 160 | .3421 | .0549 | |||

| 0.382 | 0.896 | 5.22 | .4110 | .0328 | ||||

| 1 1/2 | 1.90 | 0.145 | 1.610 | 2.72 | STD | 40 | .3262 | .1058 |

| 0.200 | 1.500 | 3.63 | XHY | 80 | .4118 | .0918 | ||

| 0.281 | 1.338 | 4.86 | 160 | .5079 | .0730 | |||

| 0.400 | 1.100 | 6.41 | .5977 | .0494 | ||||

| 2 | 2.375 | 0.109 | 2.157 | 2.64 | 10 | .4205 | .1898 | |

| 0.154 | 2.067 | 3.66 | STD | 40 | .5606 | .1743 | ||

| 0.218 | 1.939 | 5.03 | XHY | 80 | .7309 | .1534 | ||

| 0.250 | 1.875 | 5.68 | .8045 | .1434 | ||||

| 0.281 | 1.813 | 6.29 | .8666 | .1344 | ||||

| 0.344 | 1.687 | 7.47 | 160 | .9806 | .1161 | |||

| 0.436 | 1.503 | 9.04 | XXHY | 1.1043 | .0922 | |||

| 2 1/2 | 2.875 | 0.120 | 2.635 | 3.53 | 10 | .6870 | .2833 | |

| 0.203 | 2.469 | 5.80 | STD. | 40 | 1.0640 | .2487 | ||

| 0.216 | 2.443 | 6.14 | 1.1169 | .2435 | ||||

| 0.250 | 2.375 | 7.02 | 1.2468 | .2301 | ||||

| 0.276 | 2.323 | 7.67 | XHY | 80 | 1.3386 | .2202 | ||

| 0.375 | 2.125 | 10.02 | 160 | 1.6371 | .1842 | |||

| 0.552 | 1.771 | 13.71 | XXXHY | 1.9971 | .1280 |

Certifications & Quality Assurance

Quality at Lakshya Steel is our pledge not merely a method. Being a reliable Alloy Steel P22 Seamless Pipes manufacturer and supplier in India, we follow strict manufacturing and quality control standards to guarantee exceptional performance, safety, and compliance all around world markets.

From raw material procurement to final distribution, our Alloy Steel P22 Seamless Pipes are thoroughly inspected and validated at every level to guarantee dimensional precision, metallurgical integrity, and long-term dependability in harsh industrial applications.

Certifications

We provide all required international certifications to meet client and regulatory expectations:

| Certification / Standard | Details |

| Mill Test Certificate (MTC) | As per EN 10204 3.1 / 3.2 |

| ISO 9001:2015 | Certified Quality Management System |

| ISO 14001:2015 | Environmental Management System |

| ISO 45001:2018 | Occupational Health & Safety Management |

| IBR Approved | Indian Boiler Regulations (For boiler-grade pipes) |

| PED 2014/68/EU | Pressure Equipment Directive – Europe |

| NACE MR0175 / ISO 15156 | For sour gas and corrosive environments |

| CE Marking | European conformity for safety and performance |

Third-Party Inspection & Testing

To assure our global customers of consistent quality, we welcome and facilitate inspection from internationally recognized third-party agencies:

- TÜV Rheinland

- SGS

- Lloyd’s Register

- Bureau Veritas (BV)

- DNV GL

- Intertek

These inspections cover dimensional analysis, surface finish, hydrostatic testing, ultrasonic testing (UT), radiographic testing (RT), PMI (Positive Material Identification), and chemical/mechanical analysis.

In-House Testing Capabilities

Our advanced testing laboratory is equipped to perform:

- Hardness Test (Brinell & Rockwell)

- Tensile & Yield Strength Test

- Impact Test (Charpy V-Notch)

- Flattening & Flaring Tests

- Hydrostatic Pressure Testing

- Microstructure & Grain Size Analysis

All test results are documented and provided with every delivery, ensuring full material traceability and compliance.

Supported by globally recognized certifications and open documentation, Lakshya Steel provides Alloy Steel P22 Seamless Pipes that fit not just ASTM/ASME criteria but also the particular quality demands of your project.

Applications of Alloy steel p22 Seamless Pipes

Trusted supplier and Alloy Steel P22 Seamless Pipe manufacturer Lakshya Steel provides high temperature and pressure resistance for important uses requiring such resistance. Our pipes, designed for strength, corrosion resistance, and endurance, find employment in many different industrial systems in a range where performance cannot be sacrificed.

Engineers and procurement experts use our Alloy Steel P22 Seamless Pipes for their outstanding mechanical qualities, creep resistance, and dependability under demanding working conditions; they conform to ASTM A335 Grade P22.

Key Applications

| Application Area | Purpose |

| Boilers and Superheaters | High-temperature and high-pressure steam transmission |

| Heat Exchangers | Efficient thermal transfer in petrochemical and power plants |

| Refinery Equipment | Handles high-pressure and corrosive fluids |

| Power Plants (Thermal, Nuclear, Gas) | Supercritical and subcritical steam line piping |

| Process Piping Systems | Used in chemical and petrochemical industries |

| Oil & Gas Pipelines | Ideal for sour service and high-stress environments |

| Fertilizer Plants | Withstands corrosive and high-pressure chemical flow |

| Marine & Shipbuilding | Durable for offshore and saltwater-based piping systems |

| Hydrogen Reformers and HRSG Units | Withstands fluctuating thermal and pressure cycles |

Product Availability & Delivery

With rapid, dependable, and flexible product availability and delivery options for Alloy Steel P22 Seamless Pipes, Lakshya Steel is dedicated to making sure your supply chain functions without problems. Whether you are sourcing for normal operations or overseeing a vital infrastructure project, we guarantee timely delivery supported by strategic inventories and robust logistics.

In-Stock Inventory

To address current project needs, we keep a strong inventory of Alloy Steel P22 Seamless Pipes in all diameters, wall thicknesses, and lengths. Our stock ready for dispatch consists in:

- Outer Diameter: ½” to 24”

- Wall Thickness: Sch 20 to Sch XXS

- Lengths: Single Random, Double Random & Custom Cut Lengths

- Surface Finish: Black, Bare, Coated, Pickled, or Polished

- Quick Dispatch: Orders can be processed and shipped within 2–5 working days, depending on stock and destination.

Minimum Order Quantity (MOQ)

We cater to both small-scale needs and large industrial orders. Whether you’re a startup EPC contractor or a multinational manufacturer, we offer:

- Low MOQ for R&D and Prototyping

- Bulk Supply Contracts for Long-Term Projects

Customization Options

We offer tailored solutions to fit your exact specifications:

- Cut-to-Length Pipes

- Custom Bending & Shaping

- Marking & Stamping

- Protective Coatings (Oil Coated, Varnished, Galvanized, etc.)

- Packaging: Wooden boxes, steel strips, plastic wrapping as per export standards

- Global Shipping & Documentation

All exports are handled with complete documentation and care, including:

- Commercial Invoice

- Packing List

- Mill Test Certificate (EN 10204 3.1/3.2)

- Certificate of Origin

- Third-Party Inspection Reports (if requested)

- Custom Clearance Assistance

Choose Lakshya Steel for dependable product availability, customized delivery, and on-time execution — ensuring that your operations stay ahead of schedule and within budget.

What is the Price of Alloy Steel P22 Seamless Pipe Per KG in India?

Key Pricing Factors:

- Pipe Size & Thickness: Larger diameters and heavier wall thicknesses increase material cost.

- Material Grade & Standards: Pipes manufactured as per ASME SA335 or ASTM A335 may carry a premium due to stricter compliance.

- Quantity Ordered: Bulk purchases or long-term contracts can help lower per-unit costs.

- Surface Finish & Customization: Coated, pickled, or beveled pipes may incur additional charges.

- Third-Party Inspection Requirements: Charges for agencies like TUV, SGS, or DNV can impact pricing.

- Market Conditions: Alloy prices and supply-demand dynamics also play a role.

Typical Price Range (As of 2025):

| Product Type | Estimated Price (INR/KG) |

| Alloy Steel P22 Sch 40 Pipe | ₹180 – ₹210 |

| Alloy Steel P22 Sch 80 Pipe | ₹210 – ₹250 |

| Alloy Steel P22 Sch 160 / XXS | ₹250 – ₹280 |

Example Price Estimate:

For a 1000 KG order of ASME SA335 P22 Seamless Pipes in Sch 80, the total landed cost (excluding GST & freight) may range between ₹2,10,000 to ₹2,40,000.

Why Choose Lakshya Steel?

Regarding the procurement of high-performance alloy steel seamless pipes, Lakshya Steel is one of the reputable, dependable, and internationally known producer and supplier. Having decades of industry expertise and a reputation based on quality, accuracy, and customer satisfaction, we are the recommended partner for B2B customers in the power, petrochemical, refinery, and infrastructure sectors.

1. Industry-Leading Experience

With 25+ years in the steel industry, Lakshya Steel has deep technical expertise and market knowledge to fulfill complex project requirements with confidence.

2. Certified & Quality-Driven Manufacturing

We follow strict international standards and hold multiple certifications:

- ISO 9001:2015 – Quality Management

- ISO 14001:2015 – Environmental Management

- PED 2014/68/EU, IBR, CE Marking – Our pipes undergo 100% quality checks, non-destructive testing, and third-party inspections (TUV, SGS, BV) as per client requirements.

3. Wide Product Range & Customization

Whether you need ASME SA335 P9, P22, P11 alloy steel pipes, we offer:

- Sizes: 1/2″ NB to 24″ NB

- Schedules: SCH 40, 80, 160, XXS

- Lengths: Cut-to-length, fixed, or random

- End Options: Beveled, plain, threaded

- Surface Finish: Bare, pickled, painted, or coated

4. Strong Global Export Network

We export to over 35+ countries, including the USA, UAE, Saudi Arabia, South Africa, Singapore, UK, and Australia — delivering products that comply with destination country regulations and documentation.

5. Quick Delivery & In-Stock Inventory

Lakshya Steel maintains a ready stock of popular grades and sizes, enabling fast dispatch and short lead times. We support:

- Small MOQ orders for urgent needs

- Bulk supplies for long-term contracts

- Flexible logistics solutions – FOB, CIF, Ex-Works

6. Customer-Centric Approach

We go beyond just delivering pipes. Our team provides:

- Technical consultation and material selection support

- Order tracking and real-time updates

- Responsive after-sales service and client satisfaction guarantees

7. Competitive Pricing Advantage

Thanks to strong supplier relationships, in-house processing, and optimized operations, we offer cost-effective pricing without compromising on quality — giving our customers excellent value.

Trusted by Industry Leaders

From EPC contractors and OEMs to government undertakings and multinational corporations, Lakshya Steel is a name synonymous with quality, reliability, and professionalism.

Frequently Asked Questions (FAQs)

What standards do P22 pipes adhere to?

Alloy Steel P22 pipes are manufactured as per ASTM A335 and ASME SA335 standards.

Can P22 pipes be used in high-temperature environments?

Yes, P22 pipes are specifically designed for high-temperature, high-pressure service in boilers and heat exchangers

Are custom sizes and lengths available?

Absolutely. Lakshya Steel offers custom dimensions to match your project specifications

What is the lead time for large or bulk orders?

Delivery time depends on order size and destination. Please contact our sales team for accurate timelines.

Do your P22 pipes come with test certifications?

Yes, all pipes are delivered with detailed test certificates, including chemical and mechanical reports.

Our Products

Our Latest Blogs

Complete Guide to 304 Stainless Steel Tubes (304 SS Tubes)

Introduction to 304 Stainless Steel Tubes Industrial piping and construction is an industry that...

Hastelloy C276 Round Bars: Complete Guide

Hastelloy C276 is a superalloy that is known to be very versatile and possess remarkable high...

SAE 8620 Alloy Steel: Chemical Composition, Heat Treatment & Applications

SAE AISI 8620 steel is a widely used alloy that is prized for its combination of strength,...

Related Products

Send Us Message

Got a question? We'd love to hear from you. Send us a message & we'll respond as soon as possible.