AISI 3310/EN36 Alloy Steel

Specification

Manufacturing Standards

EN36 round bar, EN36 steel mechanical properties,

Detailed Information

Manufacturer & Supplier of AISI 3310/EN36 Alloy Steel in Mumbai, India

According to the BS970 standard, EN36 case hardened steel is split into three types: EN36A, EN36B, and EN36C, all of which are Ni-Cr-Mo alloy steels.

EN36 series steels are case hardening of steel, with a high surface hardness, high strength, and a soft core without sacrificing strength. To achieve high strength and hardness, EN36 series steel can also be quenched and tempered.

EN36 steel is commonly used in mechanical engineering to make mechanical parts with high wear resistance, such as gears, screws, shafts, rollers, and so on. It’s also employed in aviation engineering, shipbuilding, the railway sector, the oil industry, and a variety of other fields.

Cities We Delivered

CHEMICAL COMPOSITION OF EN36 STEEL

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| EN36A | ≤0.15 | 0.1-0.35 | 0.3-0.6 | ≤0.05 | ≤0.05 | 0.6-1.1 | 3.0-3.75 | – |

| EN36B | 0.12-0.18 | 0.1-0.35 | 0.3-0.6 | ≤0.05 | ≤0.05 | 0.6-1.1 | 3.0-3.75 | – |

| EN36C | 0.12-0.18 | 0.1-0.35 | 0.3-0.6 | ≤0.05 | ≤0.05 | 0.6-1.1 | 3.0-3.75 | 0.10-0.25 |

EN36 STANDARD FOR STEEL AND EQUIVALENT GRADE

Japan: SNC815

Europe:15NiCr13| DIN 1.5752

FORGING OF EN36 STEEL

- Initial Forging Temperature:1180-1200℃

- Final Forging Temperature:800-850℃

- Heating Rate:Strictly control the heating speed, which should be uniform and stable to prevent cracking caused by improper heating.

- Holding Time:Ensure that the material is fully and evenly heated,and the holding time should not be too long or too short.

- Forging Ratio:above 4:1

- Post-Forging Treatment:EN36 steel must be annealed after forging.

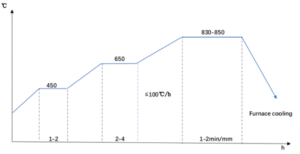

HEAT TREATMENT OF STEEL EN36

- Annealing:830 – 850°C, Cooling in a furnace, hardness below 229 HBW

EN36 Steel Annealing Diagram

- Carburizing:880-980°C

- Core Hardening:840-880°C

- Case Hardening:780-820°C

- Tempering:150-200°C

Mechanical Properties of EN36 Steel According to BS970

| Property | EN36A | EN36B | EN36C |

| Tensile Strength Mpa | ≥850 | ≥1004 | ≥1004 |

| Elongation, % | ≥15 | ≥13 | ≥13 |

| impact,J | ≥35 | ≥30 | ≥30 |

Hot Rolled Round bar:Φ16-Φ130mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

RFQ For AISI 3310/ EN36

Our Products

Our Latest Blogs

Complete Guide to 304 Stainless Steel Tubes (304 SS Tubes)

Introduction to 304 Stainless Steel Tubes Industrial piping and construction is an industry that...

Hastelloy C276 Round Bars: Complete Guide

Hastelloy C276 is a superalloy that is known to be very versatile and possess remarkable high...

SAE 8620 Alloy Steel: Chemical Composition, Heat Treatment & Applications

SAE AISI 8620 steel is a widely used alloy that is prized for its combination of strength,...

Related Products

- Stainless Steel 304 Flanges

- Stainless Steel 304L Flanges

- Stainless Steel 304H Flanges

- Stainless Steel 310 Flanges

- Stainless Steel 310S Flanges

- Stainless Steel 310H Flanges

- Stainless Steel 316 Flanges

- Stainless Steel 316L Flanges

- Stainless Steel 316H Flanges

- Stainless Steel 316Ti Flanges

- Stainless Steel 321H Flanges

- Stainless Steel 347 Flanges

- Stainless Steel 904L Flanges

Before You Go…

would you like a copy of our Handy Guide to leasing an industrial unit straight to your inbox?

Error: Contact form not found.