At Lakshya Steel, we specialize in manufacturing and supplying top-grade U-channels and C-channels for diverse industrial applications. Our high-quality steel channels ensure strength, security, and performance in demanding construction and engineering projects.

This guide will help you understand the differences between U-Channel and C-Channel. It will also explain key structural channel terms. At the end of the article, you’ll find some helpful recommendations.

Due to their strength and security, steel channels are commonly used in bridges, wall studs, rafters, and wooden beams. These versatile components are vital in construction and engineering applications, as they support heavy equipment and machinery while reducing noise and vibration.

To better understand their role in various construction needs, let’s explore the different types of steel channels and their specific uses. Continue reading to learn more about how these channels contribute to building projects.

U-channel ( Overview )

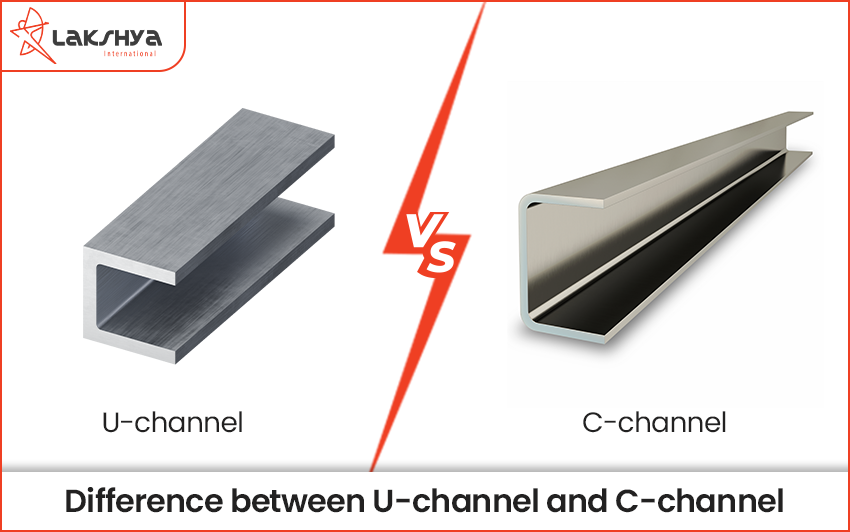

- Design: The U Channel has a straightforward shape, resembling the letter “U.” It consists of a flat base with two parallel sides (flanges) extending upwards at right angles. These flanges are typically shorter and do not exceed the width of the base, making the U Channel easy to recognize and use.

- Applications: U Channels are highly versatile and used for various purposes. They provide structural support, making them ideal for framing, reinforcing, and supporting structures where balanced load distribution is necessary. They are also commonly used for edge protection, safeguarding the edges of panels and boards. Additionally, U Channels serve as cable trays and tracks, helping organize cables and wiring. In construction and furniture projects, they are often used as trim or enclosures.

- Advantages:The simplicity of the U Channel’s design makes it easy to handle and install. Its uniform shape and dimensions offer versatility, allowing it to be used in a wide range of applications, from construction to industrial projects.

Lakshya Steel provides high-quality stainless steel U channels in grades 304, 316, and 317. Ideal for structural uses, they offer durability, corrosion resistance, and reliability for various applications.

For more information on U-Channels and their uses, or to get expert advice, contact us today. We’re here to help you choose the right solution for your project.

C-channel ( Overview )

- Design: The C channel, also known as a “C-beam” or “C-section,” is shaped like the letter “C.” It has a flat base with two flanges that extend upwards, often featuring a slight inward curve at the edges. These flanges are usually longer and can be tapered, which adds to the channel’s rigidity and strength.

- Applications: C channels are widely used in structural framing for buildings, such as wall studs, roof trusses, and floor joists, due to their strength and stiffness. They are also ideal for vehicle frames, providing sturdy support for chassis. In addition, they are used in heavy machinery and industrial equipment to offer structural support. C channels are commonly found in bridges, walkways, and platforms because of their excellent load-bearing ability.

- Advantages:The key advantages of C channels include their strength and rigidity, making them ideal for load-bearing applications. They are also flexible, as the length and thickness of the flanges can be customized to suit different structural requirements.

SS 321 Channels

Excellent high-temperature and corrosion resistance, ideal for aerospace and harsh environments.

SS 441 Channels

Good corrosion resistance at a lower cost, perfect for general construction and light applications.

Contact us today for expert advice and more information tailored to your needs.

Key Differences Between C Channel And U Channel

| Feature | U Channel | C Channel |

| Shape | Features a uniform “U” shape with parallel flanges of equal length. | Has a “C” shape with longer flanges that may be tapered and have inward curls. |

| Strength & Load Capacity | Ideal for light to moderate load applications. | Stronger and more rigid, suitable for heavier loads and structural support |

| Applications | Versatile for various uses such as edge protection, cable management, and trim. | Mainly used for structural support in construction, vehicle frames, and industrial machinery. |

Conclusion

Both U channels and C channels are important in construction and manufacturing, each suited for different needs. U channel steel, including stainless steel U channels, is great for lighter tasks like edge protection and containment. Stainless steel C channels and channel C steel are stronger and more rigid, making them ideal for structural and load-bearing purposes.

When choosing between C channels vs U channels, consider C channel sizes, standard sizes, and dimensions. Check a C channel dimensions chart to understand the different steel channel sections. Knowing C channel measurements, types, and whether you need a C beam or a U beam will help you select the right profile for your project.

FAQ’s

Why use C channels?

C channels are chosen for their “C” shape, which provides strong support and strength. This design makes them perfect for framing, vehicle chassis, and heavy machinery.

Is the C-channel strong?

Yes, the C-channel is strong, though it sacrifices some rigidity compared to an I-beam due to its design. It offers three flat surfaces, making it versatile for mounting.

What are the common uses of a U-channel?

U channels are used in structural framing, vehicle chassis, and machinery for strength and support in load-bearing structures like bridges and platforms.

What is the standard size of C channels?

The standard size of C channels varies, but common dimensions include heights from 1 to 12 inches and flange widths from 1 to 6 inches. For specific sizes, consult detailed product specifications.