Why Use Stainless Steel Pipe Fittings?

- Corrosion Resistance: Stainless steel fittings are ideal for challenging settings that are impacted by chemical compounds, moisture, or extremely low or high temperatures due to their high resistance to both corrosion and rust. This feature lowers the risk of leakage or breakdowns in critical applications and ensures an extended lifespan.

- Durability: Due to its high strength, stainless steel can withstand extreme pressure and rapid fluctuations in temperature. These connections are suitable for stressful applications like chemical-based businesses, power generation infrastructure, and crude oil refineries as they are constructed to withstand challenging conditions without compromising strength.

- Aesthetic Appeal: Installations where the plumbing system is noticeable benefits through the modern, polished visual appeal of stainless steel pipe fittings. due to their neat, finished appearance, they are often used in architectural projects, restaurant kitchens, and aesthetic pipes.

- Low Maintenance: Since stainless steel fittings are resistive to dirt, scale, and oxidation, they need little maintenance. Over the years, stainless steel remains intact and useful which reduces average maintenance costs in comparison to other metals which might need regular painting process, covering, or replacement.

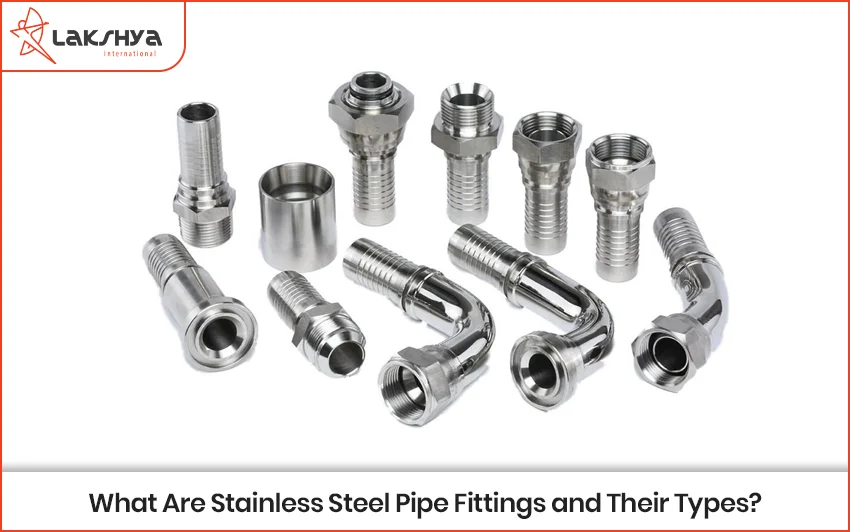

Common Types of Buttweld Pipe Fittings

Buttweld Stainless Steel Fittings

- A permanent and waterproof connection is created once these fittings are attached with solder onto the pipe.

- Varieties that comply with diverse directions and circulation needs include elbows, tees, reducers, and caps.

- SCH 10, 40, and 80 schedules are accessible to meet various pressure levels.

Forged Stainless Steel Fittings

- manufactured with machining, which improves their strength and durability.

- Offered in thread and plug welded varieties, these are ideal for applications requiring high pressure.

- Often used in the fields of power generation, chemical manufacturing, and petroleum and natural gas sectors.

Stainless Steel Elbows

- intended to shift the direction of flow through various angles, like 45°, 90°, and 180°.

- The two wide radius (for better flow quality with less pressure drop) and small radius (for installations that have restricted space) are offered.

Stainless Steel Tee Fittings

- Allows splitting out of the main pipe in order to make it easier for distributing gasses or liquids.

- They are available in two forms: diminishing tees, in which the branch size fluctuates, and equal tees, where all ends are identical in size.

Stainless Steel Threaded Fittings

- consist of connected ends which render it easy to put together and remove without requiring welding.

- Suitable for systems with low pressure and small pipeline sizes, like the ones utilized in household and plumbing usage.

Stainless Steel Reducers

- utilized for connecting pipes of various diameters, helping in reducing pressure and velocity control.

- There are two variants of reducers: eccentric reducers, which are beneficial for applications involving drainage because they feature a deviation from center line, and convergent reducers, that maintain a single center line.

Grades of Stainless Steel Pipe Fittings

304 Stainless Steel Fittings

- Due to its high durability against corrosion, it is capable of being utilized for many kinds of universal applications.

- widely used in commercial and domestic plumbing systems.

- It is affordable, flexible, and has high flexibility and weldability.

316 Stainless Steel Fittings

- Molybdenum’s integration enhances resistance to corrosion, making it suitable for petrochemical and maritime use.

- Exceptional durability under salt conditions, which reduces the risk of splitting and pitting.

- Often seen in the food processing, medicine, and shipping industries.

904L Stainless Steel Fittings

- High durability against corrosion, particularly in instances that are extremely aggressive, like phosphorous or sulfuric acids.

- Strength and durability are assured by an advanced nickel and chromium substance.

- Often found in systems like pollution prevention, saltwater management, and processing of chemicals

Contact us today for your Stainless Steel Pipe Fittings requirements and get a custom quote!

How to Choose the Right Stainless Steel Pipe Fitting

Application

- Identify the type of gas or liquid that will travel across the pipeline, its capacity to operate stress, and its degree of temperature.

- For example, due to its durability against chloride, 316 stainless steel is suggested for use in shipping operations.

Grade

- According to the environment and required durability against corrosion, choose a suitable grade.

- If the system is exposed to chemical compounds, consider fittings with 904L or 316 grade.

Type

- According to the assembling procedure, choose a suitable fitting type, like flanged, threaded, or welded.

- Although threaded fittings are easier to fit and remove, welded fittings provide a long-lasting, waterproof connection.

Size

- Ensure that it integrates into the drainage system to avoid leaks or inconsistencies.

- While acquiring, verify that the pipe has an appropriate pressure review, wall thickness, and exterior diameter.

Conclusion

To build reliable and durable piping systems, stainless steel pipe fittings are required. Considering a number of kinds, grades, and criteria while selecting fittings will assist you optimize the service life and effectiveness of your plumbing system. Whenever in doubt, seek assistance from an established manufacturer of stainless steel fittings to ensure you choose the best choice for your specific needs.

Contact Lakshay Steel today to discuss your project and find the perfect stainless steel fittings for your system!