Introduction

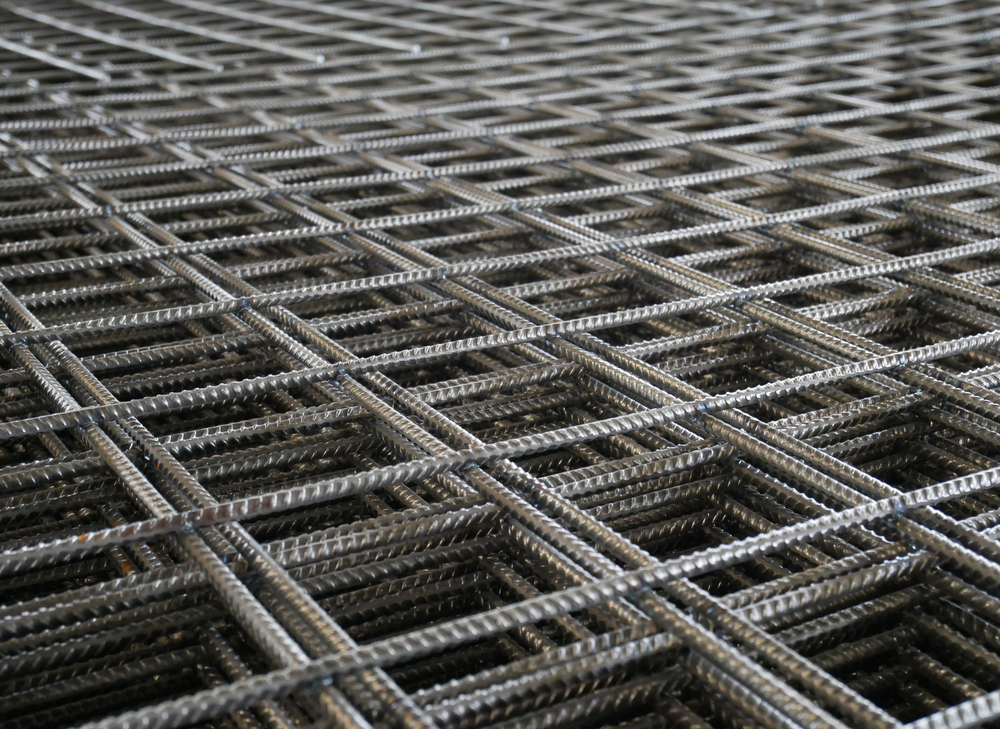

The use of stainless steel in the construction industry is increasing by the day. Why not, after all? Stainless steel is the most cost-effective and corrosion-resistant steel reinforcing alternative in most services. The need for maintenance during the project’s life cycle is considerably decreased when a structure is designed with structural steel reinforcement. As a result, while stainless steel rebars may appear to be an expensive option at first, they ultimately show to be significantly more cost-effective. For high-quality Stainless Steel Rebars for your building, what are stainless steel rebars really, and how might they help? Rebars made of stainless steel have a low carbon steel alloy percentage. They have a nickel concentration of 8 to 12 percent and chromium content of at least 12 percent. Steel becomes more robust and corrosion-resistant as a result of this process. The use of stainless steel in the construction industry is increasing by the day. Why not, after all? not? Stainless steel is the most cost-effective and corrosion-resistant steel reinforcing alternative in most services. The need for maintenance during the project’s life cycle is considerably decreased when a structure is designed with structural steel reinforcement. As a result, while stainless steel rebars may appear to be an expensive option at first, they ultimately show to be significantly more cost-effective. For high-quality Stainless Steel Rebars for your building, But what are stainless steel rebars really, and how might they help? Rebars made of stainless steel have a low carbon steel alloy percentage. They have a nickel concentration of 8 to 12 percent and chromium content of at least 12 percent. Steel becomes more robust and corrosion-resistant as a result of this process.

Types of Stainless Steel Rebars

Stainless steel comes in four main types:

Martensitic Stainless Steel

Ferritic stainless steel

Austenitic Stainless Steel

Duplex austenitic stainless steel is a type of austenitic stainless steel.

Only Austenitic and Duplex stainless steels are used for reinforcement bars. You can choose a high-durability steel product.

Stainless steel rebar constructed of austenitic austenitic

Austenitic steel has a high nickel concentration (around 7 percent ). As a result, the alloy is exceptionally weldable and malleable, as well as having excellent corrosion resistance. It also contains a considerable amount of chromium and a molybdenum addition of 2% to 3%. This increases its corrosion resistance in harsh environments, particularly when chlorides are present. The nitrogen content provides tensile characteristics and a higher yield. Austenitic steel is often used as reinforcing bars in industrial pipelines and architectural projects due to its great flexibility, diamagnetic character, and wide temperature range. It is classified into different categories in different countries based on the proportion of components present.

Duplex stainless steel rebar or Austenitic-Ferritic stainless steel rebar

Duplex stainless steels are a superb combination of ferritic and austenitic steels that are stronger than both and are commonly used in the subsea oil industry. This is because of its great corrosion resistance, which enables it to withstand highly corrosive saline for extended periods of time. Rebar is the most common use for this metal. The combination of Austenitic and Ferritic stainless steel has provided an outstanding element of strength and durability to structure boards, obstruction, and concrete structures, grounding processes and dovetail joints, chemical manufacturing facilities, coastline piers, and wharves, structure railings, sidewalks, and bridge pilings. Duplex Stainless Steel has a lower nickel concentration than Austenitic steel, making it less expensive. Steel is classified into a variety of categories as well. You can receive good steel products from JSW steel dealers in Chennai if you consider the following things.

Characteristics of Stainless Steel Rebars

Stainless steel reinforcement bars have been put to a range of tests to see how they stack up against other rebars. They’ve risen to the top of the rankings thanks to a variety of alloys that distinguish them from other useless and weak rebar alternatives.

Steel with an Extremely High Hardness

The chromium concentration of stainless steel is 10% higher than that of some other alloying components. The major component that increases the material’s strength and hardness is chromium. Nickel is also present, providing similar advantages while retaining ductility and hardness. In terms of strength, duplex steel bars surpass austenitic steel bars.

Corrosion Resistance

The high chromium content of stainless steel rebars produces an oxide covering that prevents corrosion. This feature enables it to withstand the harmful effects of chloride, which is found in road salts, the ocean, and even concrete. Austenitic stainless steel offers the best corrosion resistance since it includes at least 16 percent chromium.

Ductility

The inclusion of nickel in stainless steel rebar makes it ductile. Due to their high ductility and corrosion resistance, these rebar materials are ideal for use in earthquake-prone areas, freezing operations, railroads, and other applications. Check to visit Lakshya International to learn more about the qualities of steel bars.

Reaction to Magnetism

Because of their high nickel content, stainless steel bars have a poor magnetic response. Normal carbon steel cannot be used in many applications due to its high magnetic permeability. Stainless steel rebars come to the rescue!

Tolerance to fire

Stainless reinforcement bars perform better at higher temperatures than standard carbon steel bars. They are more fire-resistant due to their high potency retention factor at higher temperatures (above 500°C).

Cryogenics Resistance

Stainless reinforcement bars can survive a wider temperature range than steel reinforcement bars. Even at sub-zero temperatures, austenitic steel keeps its strength and modulus of elasticity, allowing it to be employed in a number of applications.

Read More :

Understanding the various applications of stainless steel pipes in various industries: With so many different types of Stainless-steel pipes, like seamless pipes, welded pipes, and flanges, it might be hard to choose which one to use for your business, or even what they can be used for. It’s important to know the different types of pipes and what they’re used for if you want to be a good plumber.

Grade 304 Stainless Steel: Everything You Need to Know : Stainless Steel is a popular option for kitchen appliances and other products. This metal has a low cost and durability, and it can be found in both sheet and plate forms. However, there are pros and cons of this stainless steel. This blog article breaks down the benefits of 304-grade stainless steel, such as its corrosion resistance and heat tolerance.