Pipes and Tubes Overview

A Tube is a round, rectangular, square, or oval hollow segment defined by outside diameter and wall thickness, represented in inches or millimeters, for the flow of fluids and gases; a Pipe is a round tubular for the flow of fluids and gases, defined by a nominal pipe size providing a rough representation of the pipe conveyance capacity; a Pipe is a round, rectangular, square, or oval hollow segment defined by outside diameter and wall thickness, represented in inches or millimeters.

When choosing a tubing type, the possibilities can be bewildering; both aluminium and stainless steel come in a multitude of alloys and tempers, each with its own set of physical and mechanical attributes. All of the alloys of that metal have specified general features.

Why Aluminium Pipes and Tubes

Aluminium is notable for its low density as well as its ability to resist corrosion via the passivation process. Aluminium and its alloys are critical in the aerospace industry, as well as in the automobile and construction industries, where they are used in things like facade design and window frames. The oxides and sulfates are the most essential components in aluminium.

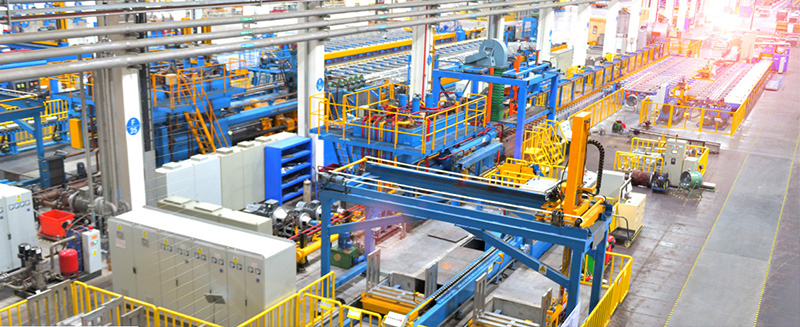

The aluminium tube is used in a wide range of industrial applications, including consumer goods, recreational goods, machine parts, automotive, and manufacturing. Aluminium is valued by suppliers for its strength, even though it is just 1% of the weight of steel.

Several buildings benefit from the successful usage of the aluminium tubes because of their diverse blend of strength and flexibility. Aluminium tubing has a higher capacity per weight than steel tubing due to its lightweight. Many goods, particularly those that require a degree of movement, such as wheelchairs and outdoor furniture, benefit from the adoption of lighter tubing material.

Aluminium pipes are comparatively strong and thus it becomes the right fit to be used in various applications.

Properties of Aluminium Pipes and Tubes

Aluminium tubing has a higher volume per weight purchased than steel tubing due to its lightweight. Many goods, particularly those that require a degree of movement, such as wheelchairs and outdoor furniture, benefit from the adoption of lighter tubing material. The aluminium tube also doesn’t tarnish and is more susceptible to paint and other embellishments than other metals, which adds to its charm. Aluminium tubing is a perfect alternative for applications requiring temperature management, such as refrigerators, solar power, and air conditioning systems because it transfers heat exceedingly well.

Aluminium tubing’s lightweight and durability are also advantageous in applications like hydraulic systems, fuel lines, frames, and racks.

Aluminium is available in a variety of alloys. Aluminium can be combined with a range of magnesium and silicon alloys to create strong alloys. Because of its better weldability and outstanding corrosion resistance, manufacturers employ the aluminium square tube alloy 6061 for numerous medium- to high-strength applications. The 6061 aluminium seamless pipe square tube anodizes easily and is ideal for heat treatment due to its characteristics. It’s also the cheapest aluminium tube alloy on the market.

Uses of Aluminium Pipes and Tubes

Aluminium tubes and pipes are utilized in a variety of applications.

Aluminium pipes and tubes are generally utilized for various industrial or building purposes, however, they have been modified for common residential use by homeowners and vehicle manufacturers.

Aluminium pipes are also used in the need for interior furnishings. Wrought iron is commonly used in the construction of canopy beds and bedside tables. Aluminium tubes are a lightweight option that gives the area a modern feel.

Several fasteners are available for the threaded tubes. Aluminium pipe is a machined component that is frequently employed in a variety of industrial projects where weight and corrosion resistance are important. Aluminium seamless pipes are 6061-T6 and 6063- T6. Both 6061-T6 and 6063-T6 may be printed, although 6063 has a smoother texture and is more flexible than 6061.

Conclusion

Lakshya International is a B2B portal that specializes in industrial, metal, and piping products. We also share the latest information and news related to products, materials, and different types of grades to help businesses dealing in this industry. For more information visit our website and also check out our other blog sections to gain industrial knowledge for your business.