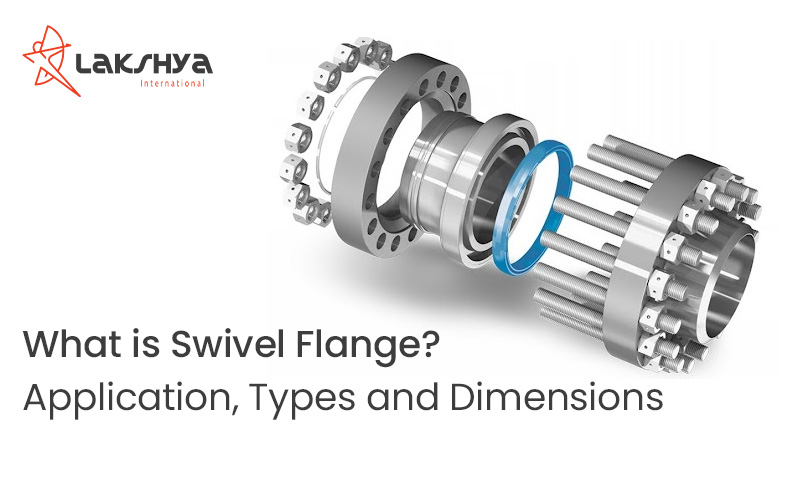

Swivel flange serves as a vital component in pipe systems, facilitating the connection between two pipe segments. Its distinctive feature is the ability to rotate freely, a quality that proves invaluable in scenarios demanding independent movement of connected pipes. This article delves into the world of swivel flanges, exploring their composition, applications, and the various types available.

A swivel flange comprises two primary components: the flange itself and the swivel nut. The flange takes the form of a flat disc, meticulously perforated with holes to accommodate bolts or nuts. The swivel nut, on the other hand, permits unhindered rotation of the pipe while ensuring a secure attachment. This ingenious design enables pipes to move independently without imposing undue stress on either one. Consequently, swivel flanges offer an ideal solution for applications necessitating pipe movement while maintaining a secure connection.

Swivel Flanges Applications

Swivel flanges find widespread utility across various industries, with plumbing and construction sectors being their primary domains. These ingenious components prove especially handy when joining radiators or other piping systems. They empower pipes to move autonomously without the need for disconnection every time motion occurs between them. Additionally, swivel flanges simplify the installation of piping systems in confined spaces or around obstacles like walls and floors, thanks to their enhanced flexibility.

Welding Swivel Flanges

Welding a swivel flange demands specialized expertise and equipment, as it involves simultaneously welding both materials. This process should ideally be entrusted to seasoned professionals well-versed in working with metals and experienced in welding pipe joints. Their expertise ensures a leak-free assembly once everything is correctly aligned. Moreover, strict adherence to safety protocols during welding is crucial, as sparks generated during the process can pose potential hazards if not managed meticulously.

Types of Swivel Flanges

A diverse array of swivel flange types is available to cater to distinct requirements. Among these, slip-on swivels, which employ standard bolts, and welded neck swivels, which necessitate additional support, are prominent options. Additionally, half-moon or oval-shaped swivels stand out due to their curved design, facilitating a snug fit in tight spaces such as against walls or floors. This design flexibility surpasses that of traditional straight-edged models. Lastly, adjustable swivel nuts, tightened using an Allen key, offer enhanced security, making them well-suited for high-pressure applications like steam lines or water mains.

Swivel Flange Dimension

| Nominal Hose Size | Weight of Fitting | Fitting Length AASA150 | Flared Diameter DASA150 | Fitting Inside Diameter IASA150 | †3A | |||||

| in | mm | in | mm | in | mm | in | mm | in | mm | |

| 1 | 25 | 1.20 | 2.63 | 2.36 | 60.00 | 2.00 | 50.80 | 0.85 | 21.50 | √ |

| 1 1/4 | 32 | 1.59 | 3.50 | 2.67 | 67.72 | 2.50 | 63.50 | 1.03 | 26.21 | √ |

| 1 1/2 | 40 | 2.15 | 4.73 | 2.75 | 69.86 | 2.87 | 73.00 | 1.25 | 31.75 | √ |

| 1/2 | 13 | 0.57 | 1.25 | 1.67 | 42.50 | 1.38 | 35.00 | 0.37 | 9.40 | – |

| 3/4 | 20 | 0.84 | 1.84 | 1.86 | 47.24 | 1.69 | 42.90 | 0.62 | 15.75 | √ |

| 2 | 50 | 2.92 | 6.41 | 3.20 | 81.22 | 3.62 | 92.00 | 1.76 | 44.60 | √ |

| 21/2 | 65 | 4.36 | 9.59 | 3.70 | 94.00 | 4.13 | 105.00 | 2.25 | 57.15 | √ |

| 3 | 80 | 6.02 | 13.24 | 3.74 | 95.00 | 5.00 | 127.00 | 2.63 | 66.70 | √ |

In Conclusion

In summary, swivel flanges emerge as a versatile solution for securely connecting two pipe segments while permitting independent movement when needed. Their adaptability extends their applicability across multiple industries, including plumbing, construction, and various engineering-related endeavors. Whether your project calls for a straightforward slip-on model or an adjustable nut variant, understanding the specific requirements will guide you toward selecting the most suitable option. The combination of versatility and ease of use positions swivel flanges as an attractive choice for expeditious yet reliable piping system installations. Lakshya International offers the best SS Flanges for you. Contact Today!