A flange rating, also known as a flange class or pressure class, is a numerical designation that indicates the maximum allowable pressure and temperature that a flange can withstand. Flange ratings are standardized by various organizations, such as the American Society of Mechanical Engineers (ASME) and the American National Standards Institute (ANSI).

Flange Class

Flange class is another term for flange rating. The flange class is typically indicated by a number, such as class 150, class 300, class 400, class 600, class 900, class 1500, and class 2500 pressure rating. The higher the number, the higher the pressure and temperature rating of the flange.

Types of Flanges Rating

Flanges are crucial components in piping systems, enabling the connection and disconnection of pipes while maintaining pressure containment. To ensure compatibility and safety in piping systems, flange ratings are standardized by organizations like the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME). These standards define the maximum allowable working pressure and temperature for flanges, ensuring that they can safely handle the required operating conditions.

The two most common flange rating standards are:

ANSI/ASME B16.5: This standard covers flanges and flanged fittings with nominal pipe sizes (NPS) ranging from ½ inch (DN 15) to 24 inches (DN 600). It specifies pressure classes from 150 to 2500, where each pressure class denotes the flange’s maximum allowable working pressure at various temperatures.

ANSI/ASME B16.47: This standard covers larger flanges with NPS ranging from 26 inches (DN 650) to 60 inches (DN 1500). It specifies pressure classes from 75 to 900, following the same principle of defining maximum allowable working pressure based on temperature.

How Flange Rating Works

The pressure rating of a flange is determined by its Maximum Allowable Working Pressure (MAWP) at a specific temperature and for a particular material. The flange’s pressure class is designated according to its highest pressure and temperature ratings, along with the manufacturing material. These highest pressure and temperature ratings are commonly known as ‘pressure-temperature ratings.

In the oil, gas, and petrochemical industries, it’s important to make sure that the flanges can handle the pressures and temperatures they’re put through. The size of the flanges is important, but the rating is also important. So, choosing a flange with the right rating makes sure it can handle the stresses of working at different temperatures.

The class of the flange tells how much pressure a flange can handle when the temperature is high or rising. Flanges with a higher flange rating or flange class are thought to be stronger because they can handle more pressure at higher temperatures.

The industry standard for flanges is the ASME B16.5 standard, which is used for both flanged fittings and pipe flanges. This has flanges with diameters between 12′′ NPS and 24′′ NPS.

So, when the temperature goes up, the maximum pressure goes down. Flange rating is easy to explain with the help of the following example.

A Class 300 flange can handle more pressure than a Class 150 flange because it is made of more metal and can handle more pressure. But there are many things that can change how much pressure a flange can handle.

A Class 300 flange can handle more pressure than a Class 150 flange because it is made of more metal and can handle more pressure. On the other hand, different things affect how much pressure a flange can handle.

ANSI 6 Inch Flange Pressure Rating Dimensions & Weight

Flange Pressure Rating Example:

If two flanges have the same bore size, say 6 inches, and the same material, say A105, but different pressure ratings, say class 150 and class 300, the class 150 flange will be smaller, lighter, and less strong than the class 300 flange (class 300). What the picture shows is this:

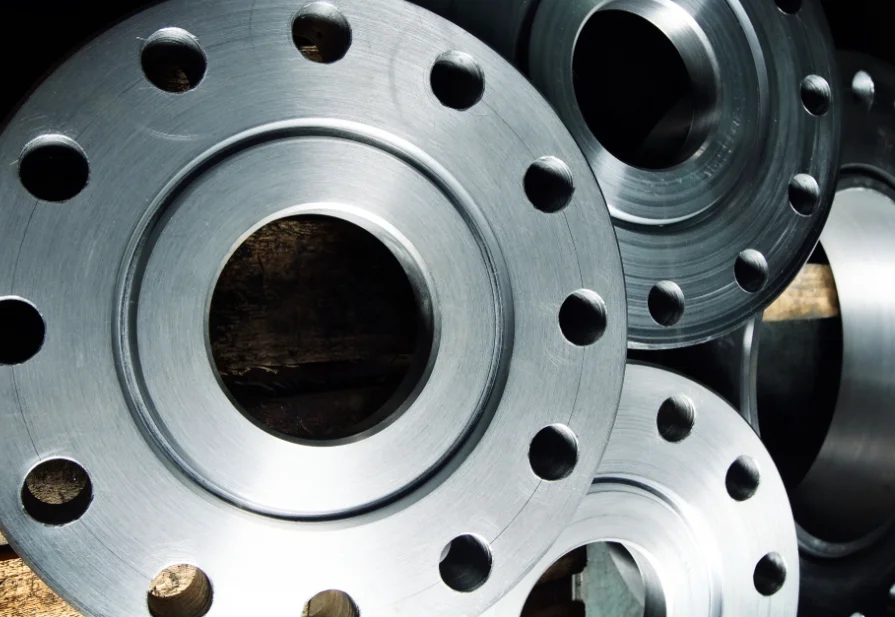

What is a Flange? and how does it do what it does?

A flange is a piece of equipment that connects pipes, pumps, valves, and other piping parts to make a pipeline system. The flange is a key part of the piping system because it makes cleaning, checking, and making changes easier. There are many different kinds of flanges, such as Weld Neck Flange, Slip-on Flange, Socket Weld Flanges, Lap Joint Flange, Threaded Flanges, Blind Flange, Orifice Flanges, Reducing Flanges, and Blind Flanges.

Flange Rating Chart

CARBON STEEL FLANGE RATING CHART

Carbon steel flange pressure-temperature rating ASME

ANSI Flange ASTM A105, A350 Gr. LF2/LF6 Class 1

The ANSI A105, A350 Gr. LF2/LF6 Class 1 standard for flanges defines a series of flange classes, each with a specific pressure and temperature rating. The following table shows the ANSI flange pressure classes and their corresponding pressure and temperature ratings:

The maximum pressure for flanges of classes 150/300/400/600/900/1500/2500 at increasing temperatures (Celsius or Fahrenheit) – in PSI – is shown in the flange rating table.

| ANSI/ASME B16.34 | Flange Pressure Rating | ||||||

| Temperature (in F°) | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| < 100 | 285 | 740 | 985 | 1480 | 2220 | 3705 | 6170 |

| 200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5655 |

| 300 | 230 | 655 | 870 | 1310 | 1965 | 3270 | 5450 |

| 400 | 200 | 635 | 845 | 1265 | 1900 | 3170 | 5280 |

| 500 | 170 | 605 | 805 | 1205 | 1810 | 3015 | 5025 |

| 600 | 140 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 650 | 125 | 550 | 730 | 1100 | 1650 | 2745 | 4575 |

| 700 | 110 | 530 | 710 | 1060 | 1590 | 2655 | 4425 |

| 750 | 95 | 505 | 675 | 1015 | 1520 | 2535 | 4230 |

| 800 | 80 | 410 | 550 | 825 | 1235 | 2055 | 3430 |

| 850 | 65 | 320 | 425 | 640 | 955 | 1595 | 2655 |

| 900 | 50 | 230 | 305 | 460 | 690 | 1150 | 1915 |

| 950 | 35 | 135 | 185 | 275 | 410 | 685 | 1145 |

| 1000 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| Hydrostatic Test Pressure (in Psig) | 450 | 1125 | 1500 | 2225 | 3350 | 5575 | 9275 |

Notes

The maximum pressure for flanges of classes 150/300/400/600/900/1500/2500 at increasing temperatures (Celsius or Fahrenheit) – in bars – is shown in the flange rating table.

| ANSI/ASME B16.34 | Flange Pressure Rating | ||||||

| Temperature in C° | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -29 / 38 | 19.6 | 51.1 | 68.1 | 102.1 | 153.2 | 255.3 | 425.5 |

| 50 | 19.2 | 50.1 | 66.8 | 100.2 | 150.4 | 250.6 | 417.7 |

| 100 | 17.7 | 46.6 | 62.1 | 93.2 | 139.8 | 233 | 388.3 |

| 150 | 15.8 | 45.1 | 60.1 | 90.2 | 135.2 | 225.4 | 375.6 |

| 200 | 13.8 | 43.8 | 58.4 | 87.6 | 131.4 | 219 | 365 |

| 250 | 12.1 | 41.9 | 55.9 | 83.9 | 125.8 | 209.7 | 349.5 |

| 300 | 10.2 | 39.8 | 53.1 | 79.6 | 119.5 | 199.1 | 331.8 |

| 325 | 9.3 | 38.7 | 51.6 | 77.4 | 116.1 | 193.6 | 322.6 |

| 350 | 8.4 | 37.6 | 50.1 | 75.1 | 112.7 | 187.8 | 313 |

| 375 | 7.4 | 36.4 | 48.5 | 72.7 | 109.1 | 181.8 | 303.1 |

| 400 | 6.5 | 34.7 | 46.3 | 69.4 | 104.2 | 173.6 | 289.3 |

| 425 | 5.5 | 28.8 | 38.4 | 57.5 | 86.3 | 143.8 | 239.7 |

| 450 | 4.6 | 23 | 30.7 | 46 | 69 | 115 | 191.7 |

| 475 | 3.7 | 17.4 | 23.2 | 34.9 | 52.3 | 87.2 | 145.3 |

| 500 | 2.8 | 11.8 | 15.7 | 23.5 | 35.3 | 58.8 | 97.9 |

Notes:

ASTM A105 says that when steel is heated above 425°C for a long time, its carbide phase changes into graphite (this material is not recommended for consistent temperatures above this number).

According to the ASTM A350 LF6 standard, it shouldn’t be used at temperatures higher than 260 degrees Celsius.

ANSI Flange ASTM A350 Gr. LF3, A350 LF6, Class 2

The flange rating chart shows the maximum pressure (in PSI) for flanges of classes 150/300/400/600/900/1500/2500 at different temperatures (in degrees Celsius or Fahrenheit).

| ANSI/ASME B16.34 | Flange Pressure Rating | ||||||

| Temperature in °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 290 | 750 | 1000 | 1500 | 2250 | 3750 | 6250 |

| 200 | 260 | 750 | 1000 | 1500 | 2250 | 3750 | 6250 |

| 300 | 230 | 730 | 970 | 1455 | 2185 | 3640 | 6070 |

| 400 | 200 | 705 | 940 | 1410 | 2115 | 3530 | 5880 |

| 500 | 170 | 665 | 885 | 1330 | 1995 | 3325 | 5540 |

| 600 | 140 | 605 | 805 | 1210 | 1815 | 3025 | 5040 |

| 650 | 125 | 590 | 785 | 1175 | 1765 | 2940 | 4905 |

| 700 | 110 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 750 | 95 | 505 | 670 | 1010 | 1510 | 2520 | 4200 |

| 800 | 80 | 410 | 550 | 825 | 1235 | 2060 | 3430 |

| 850 | 65 | 270 | 355 | 535 | 805 | 1340 | 2230 |

| 900 | 50 | 170 | 230 | 345 | 515 | 860 | 1430 |

| 950 | 35 | 105 | 140 | 205 | 310 | 515 | 860 |

| 1000 | 20 | 50 | 70 | 105 | 155 | 260 | 430 |

ANSI Flange ASTM A350 Gr. LF1

The flange rating table shows the maximum pressure (in PSI) for flanges of classes 150/300/400/600/900/1500/2500 at increasing temperatures (in Celsius or Fahrenheit).

| ANSI/ASME B16.34 | Flange Pressure Rating | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 235 | 620 | 825 | 1235 | 1850 | 3085 | 1545 |

| 200 | 215 | 560 | 750 | 1125 | 1685 | 2810 | 4680 |

| 300 | 210 | 550 | 730 | 1095 | 1640 | 2735 | 4560 |

| 400 | 200 | 530 | 705 | 1060 | 1585 | 2645 | 4405 |

| 500 | 170 | 500 | 665 | 995 | 1495 | 2490 | 4150 |

| 600 | 140 | 455 | 610 | 915 | 1370 | 2285 | 3805 |

| 650 | 125 | 450 | 600 | 895 | 1345 | 2245 | 3740 |

| 700 | 110 | 450 | 600 | 895 | 1345 | 2245 | 3740 |

| 750 | 95 | 445 | 590 | 885 | 1325 | 2210 | 3685 |

| 800 | 80 | 370 | 495 | 740 | 1110 | 1850 | 3085 |

| 850 | 65 | 270 | 355 | 535 | 805 | 1340 | 2230 |

| 900 | 50 | 170 | 230 | 345 | 515 | 860 | 1430 |

| 950 | 35 | 105 | 140 | 205 | 310 | 515 | 860 |

| 1000 | 20 | 50 | 70 | 105 | 155 | 260 | 430 |

ALLOY STEEL FLANGE RATING CHART

Alloy steel flange pressure-temperature rating ASME

ANSI Flange ASTM A182 Gr. F1 (Chrome Moly)

The flange rating table shows the maximum pressure (in PSI) for flanges of classes 150/300/400/600/900/1500/2500 at increasing temperatures (in Celsius or Fahrenheit).

| ANSI/ASME B16.34 | Pressure Rating | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 265 | 695 | 925 | 1390 | 2085 | 3470 | 5785 |

| 200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5660 |

| 300 | 230 | 655 | 870 | 1305 | 1955 | 3260 | 5435 |

| 400 | 200 | 640 | 855 | 1280 | 1920 | 3200 | 5330 |

| 500 | 170 | 620 | 830 | 1245 | 1865 | 3105 | 5180 |

| 600 | 140 | 605 | 805 | 1210 | 1815 | 3025 | 5040 |

| 650 | 125 | 590 | 785 | 1175 | 1765 | 2940 | 4905 |

| 700 | 110 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 750 | 95 | 530 | 710 | 1065 | 1595 | 2660 | 4430 |

| 800 | 80 | 510 | 675 | 1015 | 1525 | 2540 | 4230 |

| 850 | 65 | 485 | 650 | 975 | 1460 | 2435 | 4060 |

| 900 | 50 | 450 | 600 | 900 | 1350 | 2245 | 3745 |

| 950 | 35 | 280 | 375 | 560 | 845 | 1405 | 2345 |

| 1000 | 20 | 165 | 220 | 330 | 495 | 825 | 1370 |

STAINLESS STEEL FLANGE RATING CHART

ANSI Flange ASTM A182 Gr. F304, 304L

The maximum pressure for flanges of classes 150/300/400/600/900/1500/2500 at increasing temperatures (Celsius or Fahrenheit) – in PSI – is shown in the flange rating table.

| ANSI/ASME B16.34 | Pressure Rating | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

The maximum pressure for flanges of classes 150/300/400/600/900/1500/2500 at increasing temperatures (Celsius or Fahrenheit) – in PSI – is shown in the flange rating table.

| ANSI/ASME B16.34 | Pressure Rating | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 235 | 620 | 825 | 1240 | 1860 | 3095 | 5160 |

| 300 | 215 | 560 | 745 | 1120 | 1680 | 2795 | 4660 |

| 400 | 195 | 515 | 685 | 1025 | 1540 | 2570 | 4280 |

| 500 | 170 | 480 | 635 | 955 | 1435 | 2390 | 3980 |

| 600 | 140 | 450 | 600 | 900 | 1355 | 2255 | 3760 |

| 650 | 125 | 445 | 590 | 890 | 1330 | 2220 | 3700 |

| 700 | 110 | 430 | 580 | 870 | 1305 | 2170 | 3620 |

| 750 | 95 | 425 | 570 | 855 | 1280 | 2135 | 3560 |

| 800 | 80 | 420 | 565 | 845 | 1265 | 2110 | 3520 |

| 850 | 65 | 420 | 555 | 835 | 1255 | 2090 | 3480 |

| 900 | 50 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 950 | 35 | 385 | 515 | 775 | 1160 | 1930 | 3220 |

| 1000 | 20 | 350 | 465 | 700 | 1050 | 1750 | 2915 |

| 1050 | 20 | 345 | 460 | 685 | 1030 | 1720 | 2865 |

| 1100 | 20 | 305 | 405 | 610 | 915 | 1525 | 2545 |

| 1150 | 20 | 235 | 315 | 475 | 710 | 1185 | 1970 |

| 1200 | 20 | 185 | 245 | 370 | 555 | 925 | 1545 |

| 1250 | 20 | 145 | 195 | 295 | 440 | 735 | 1230 |

| 1300 | 20 | 115 | 155 | 235 | 350 | 585 | 970 |

| 1350 | 20 | 95 | 130 | 190 | 290 | 480 | 800 |

| 1400 | 20 | 75 | 100 | 150 | 225 | 380 | 630 |

| 1450 | 20 | 60 | 80 | 115 | 175 | 290 | 485 |

| 1500 | 20 | 40 | 55 | 85 | 125 | 205 | 345 |

Read More :

Understanding how stainless steel pipes can be used in different fields: Because welded pipes are so versatile, they can be used in almost any kind of business. Because of this, though, they do better at resisting corrosion and less well at resisting pressure than they do at resisting rust. Welded pipes are a lot easier to work with than most other types of pipes.