What is Corten Steel?

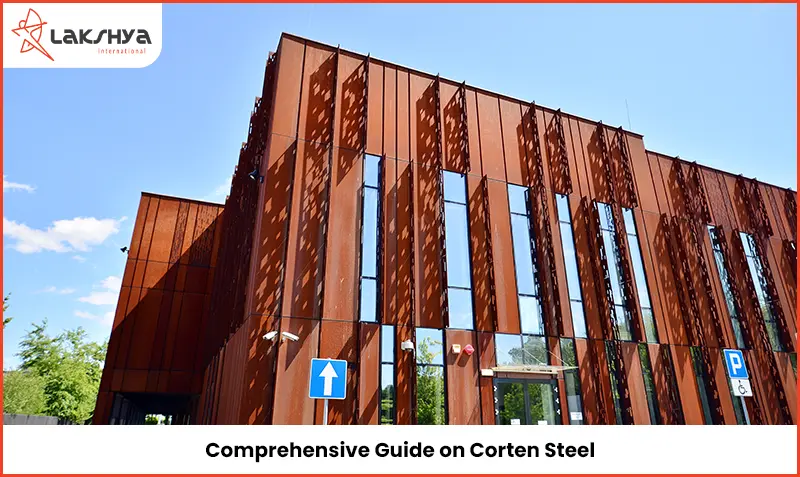

Corten steel, also known as weathering steel, is mainly used in construction and the artistic industry due to its unique properties. Originally discovered by coal wagon producers in the United States, who noticed its ability to develop a protective layer of rust that guards against further corrosion, Corten steel material is most popular among architects due to its enduring, earthy patina. This distinctive steel alloy has been refined over time to enhance its strength and durability, making it a preferred choice in contemporary architecture and sculpture.

The Origin Story of Corten Steel

In 1933, the United States introduced and patented the first Corten weathering steel under the trade name Cor-Ten®. Its name derived from its high tensile strength and low corrosion rate. Over time, the American Society for Testing and Materials (ASTM) established standards for Corten steel, leading to the interchangeable use of “CorTen” with “Cor-Ten®” from the 2000s onwards. All grades of weathering steel share similar visual and tactile characteristics, as well as corrosion resistance. Originally developed for railroad coal wagons, Corten steel gained rapid popularity in construction due to its durability and minimal maintenance requirements. By the 1950s and 1960s, artists and sculptors were drawn to Corten for its robustness and industrial aesthetic. Today, Corten steel finds widespread use, notably in shipping containers, reflecting its enduring appeal and versatile applications in modern architecture and art.

CorTen A and B

The original Corten steel, ASTM A242, is commonly referred to as Type 1 and Type 2, or CorTen A and CorTen B. CorTen A, available in thicknesses from 2mm to 12mm, is known for its standard composition. On the other hand, CorTen B, which includes vanadium for added strength, is suitable for heavy structural use and comes in thicknesses ranging from 2mm to 40mm. In India, Steel Grade S355JOWP corresponds to CorTen A, while S355JOW and S355J2W are equivalents of CorTen B. S355J2W, a cost-effective option, offers similar properties to CorTen B and is fully recyclable, making it a sustainable choice for various applications.

What Factors Influence the Development of Patina on Corten Steel?

Corten weathering steel combines steel with varying alloys, depending on the grade. Initially, it may appear dull and dark grey, resembling untreated steel. However, over time, each piece develops a unique patina influenced by environmental factors like humidity, temperature, and airborne particles. This natural weathering process causes oxidation to occur faster in exposed areas or where water accumulates, resulting in the distinctive earthy tones characteristic of Corten steel.

Manufacturing and Weathering Process of Corten Steel

Corten steel manufacturers produce weathering steel by subjecting metal to high-temperature heating and rolling between rollers. This process results in the emergence of mill scale, a residue from iron processing, which initially causes rust runoff and staining as weathering begins. After the initial iron waste layer rusts away, the Corten steel surface develops durability and resistance against further shedding and staining. Manufacturers may employ pickling, an acid treatment, to accelerate this process by removing mill scale before shipping, ensuring a clean and preparation-ready surface for various applications.

Why is Corten Steel So Popular?

Corten weathering steel is highly popular due to its exceptional strength, durability, practicality, and aesthetic appeal. It boasts a tensile strength of 68-78 KSI, significantly higher than galvanized steel sheets, making it capable of withstanding stronger forces without buckling or breaking. One of Corten’s standout features is its natural resistance to corrosion, thanks to a protective oxidized coating that forms over time in most environments. This coating eliminates the need for regular painting or treatment. If scratched, Corten quickly forms a new oxidized layer that blends seamlessly with the surroundings, enhancing its raw, natural beauty. In landscape architecture, Corten steel’s distinctive patina creates a striking contrast with greenery and complements natural materials like wood and stone, further fueling its popularity.

Corten Steel Composition

Corten steel is primarily composed of iron, with a small percentage of copper, chromium, and nickel. Its unique alloy composition enhances durability and forms a protective rust-like appearance over time.

Corten A Chemical Composition

| C | 0.15 |

| Si | 0.25/0.75 |

| Mn | 0.20/0.50 |

| P | 0.07/0.15 |

| S | 0.030 |

| Al | 0.015/0.06 |

| Cu | 0.25/0.55 |

| Cr | 0.50/1.25 |

| Ni | 0.65 |

Corten B Chemical Composition

| % | |

| C | 0.19 |

| Si | 0.30/0.65 |

| Mn | 0.80/1.25 |

| P | 0.035 |

| S | 0.030 |

| Al | 0.020/0.06 |

| V | 0.02/0.10 |

| Cu | 0.25/0.40 |

| Cr | 0.40/0.65 |

| Ni | 0.40 |

Corten Steel Properties

Corten steel exhibits exceptional strength and durability, with a natural resistance to corrosion that develops a distinctive, weathered patina over time.

Corten A Mechanical Properties

|

GRADE |

THICKNESS (MM) STRIP PRODUCTS |

PLATE PRODUCTS |

YIELD STRENGTH REL N/MM² MINIMUM |

TENSILE STRENGTH RM N/MM² MINIMUM |

ELONGATION A50 % MINIMUM |

|

Corten A |

2-12 |

6-12 |

345 |

485 |

20 |

Corten B Mechanical Properties

|

GRADE |

THICKNESS (MM) STRIP PRODUCTS |

PLATE PRODUCTS |

YIELD STRENGTH REL N/MM² MINIMUM |

TENSILE STRENGTH RM N/MM² MINIMUM |

ELONGATION A50 % MINIMUM |

|

Corten B |

2-13 |

6-40 |

345 |

485 |

19 |

Corten Steel Equivalent Grade

Corten Steel Equivalent Grade: In India, S355JOWP is equivalent to Corten A, while S355JOW is equivalent to Corten B, offering similar weathering characteristics and structural benefits.

Corten Steel Advantages

Corten weathering steel offers advantages:

Cost-effective: Durable with minimal maintenance, reducing long-term costs.

Long-lasting: Resilient and suitable for diverse applications.

Ideal for heavy-duty use: High tensile strength and weather resistance for structures like bridges.

Maintenance-free: Develops a protective patina, no regular painting needed.

Corten Steel Uses

Corten weathering steel is widely used in outdoor construction, especially for sculptures and structures that benefit from its ability to develop a protective rust layer for weathered aesthetics. It’s popular for bridges and smaller projects like household gardens, where it serves as an alternative to concrete walls, blending well with garden spaces. In addition to sculptures and garden walls, Corten steel is used for practical items like cycle hoops, tree grilles, and planters, enhancing both functionality and aesthetic appeal in public spaces. It’s also favored in marine transportation, intermodal container construction, and visible sheet piling due to its durability and weather resistance.

Corten Steel Supplier

At Lakshya Steel, we specialize in providing high-quality Corten steel products tailored to meet your project needs. As a trusted Corten steel supplier, we offer a comprehensive range including Corten steel plates, sheets, pipes, and tubes in various grades like ASTM A423, ASTM A847, ASTM A588 GR A, and ASTM A588 GR B. Our commitment since 1984 has been to deliver reliable solutions that withstand the elements, ensuring durability and aesthetic appeal for architectural and landscaping applications. Trust Lakshya Steel for your Corten steel requirements and experience unmatched quality and service.