Introduction

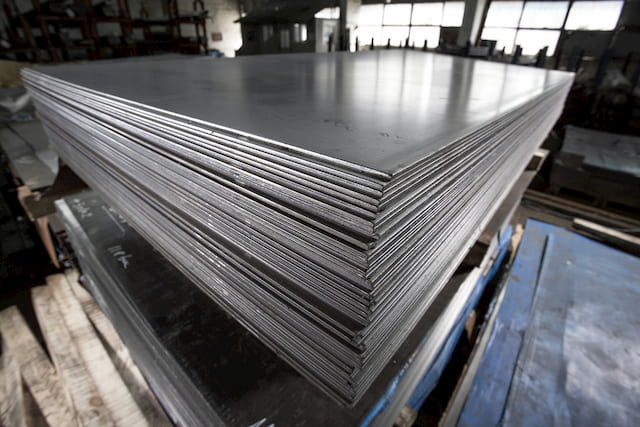

Mild steel is a type of carbon steel that has very little carbon in it. It is also called “low carbon steel.” Depending on the source, the amount of carbon in mild steel ranges from 0.05% to 0.25% by weight. On the other hand, higher carbon steels usually have a carbon content of between 0.30% and 2.0%. If more than that amount of carbon is added, the steel becomes cast iron.

Mild steel is not alloy steel, so it contains relatively few elements other than iron. It is lacking in chromium, molybdenum, and other metals that strengthen steel. Due to its low carbon and alloying element content, it possesses a few features that distinguish it from steels with higher carbon and alloying element content.

Due to its lower carbon content, mild steel is typically easier to bend, cut, and weld than high carbon steel and other steel. Additionally, this renders it nearly impossible to harden and strengthen by heating and quenching. It contains extremely little carbon and other alloying elements to inhibit dislocations in its crystal structure due to its low carbon content. Consequently, it often possesses a lower tensile strength than high carbon and alloy steels. Mild steel contains a significant amount of iron and ferrite, which makes it magnetic.

Since mild steel lacks the alloying components present in stainless steel, the iron in mild steel can rust if not properly coated. Mild steel is comparatively inexpensive compared to other varieties of steel because it has a minimum quantity of alloying elements. It is popular steel among consumers since it is inexpensive, simple to weld, and simple to deal with.

Technical Specifications of Mild Steel

| Designation | Depth of Section | Width of Flange | Thickness of Web | Weight/Mtr | Sectional Area | Moduli of Section | Moduli of Section |

| h | b | t | w | a | Zxx | Zyy | |

| (mm) | (mm) | (mm) | (kg) | (cm2) | (cm2) | (cm2) | |

| ISMC 75 weight | 75 | 40 | 4.8 | 7.1 | 9.1 | 20.3 | 4.7 |

| ISMC 100 weight | 100 | 50 | 5 | 9.6 | 12.2 | 37.3 | 7.5 |

| ISMC 125 weight | 125 | 65 | 5.3 | 13.1 | 16.7 | 68 | 13.4 |

| ISMC 150 weight | 150 | 75 | 5.7 | 16.8 | 21.3 | 105 | 19.4 |

| ISMC 175 weight | 175 | 75 | 6 | 19.6 | 24.4 | 139.8 | 22.8 |

| ISMC 200 weight | 200 | 75 | 6.2 | 22.3 | 28.5 | 181 | 26.4 |

| ISMC 250 weight | 250 | 82 | 7.2 | 34.2 | 39 | 307 | 38.4 |

| ISMC 300 weight | 300 | 90 | 7.8 | 36.3 | 46.3 | 428 | 47.1 |

| ISMC 400 weight | 400 | 100 | 8.8 | 50.1 | 63.8 | 760 | 67 |

What is the purpose of Mild Steel?

Mild steel is one of the most common varieties of steel because it has a wide range of industrial applications. Mild steel is used for building constructions, signage, automobiles, furniture, and fences, among other applications. Check out the following list to learn more about the various types of projects for which low carbon steel is an excellent option:

Steel Frame Buildings – Because of their sturdiness, mild steel beams are frequently utilized for building frameworks.

Gates and Fencing – Mild steel gates and fences provide both security and an attractive appearance, which are essential for these two goods. Low-carbon steel is difficult to break and can be coated, primed, or galvanized to prevent rust and provide an attractive surface.

Machinery Parts – One of the advantages of low-carbon steel is that it can be formed into a variety of shapes. This makes it ideal for the production of steel sheets for automobile body kits and other industrial components.

Pipelines – When consumers require steel pipes for various purposes, they frequently opt for mild steel tubes. This is because the pipes are very ductile, making them easier to weld and flexible enough to withstand pressure without breaking. These pipes can also be insulated so that they continue to function regardless of the weather. This helps to enhance the durability of the pipes.

Structural Steel – Low-carbon steel can be used when structural steel fabrication is needed because it has a consistent yield strength and is easier to shape. Mild steel can be better than structural steel for smaller building projects because it is easier to work with and costs less.

Classifications of Mild Steel

EN 1.0301 – This grade of steel has 0.1% carbon, 0.4% manganese, and 0.4% silicon, along with a few other elements that all make it easy to weld. Because of these qualities, EN 1.0301 is often used to make furniture, appliances, and car parts.

EN 1.1121 – This low-carbon steel grade has approximately 0.1% carbon and 0.45% manganese on average. This provides EN 1.1121 with a very high level of ductility, which is utilized in a variety of applications.

GET IN TOUCH WITH US FOR A FREE ESTIMATE TODAY

Read More :

Different Types of Steel Reinforcement Bars: Concrete structures use a variety of steel bar kinds. The concrete structure is strengthened with reinforced steel bars, ensuring its durability.

How Does Carbon Steel Differ from Alloy Steel? : Carbon makes up between 0.02% and 2.1% of both kinds of steel, so why is carbon steel a type of steel? Most of the time, when people say “carbon steel,” they mean either carbon steel or low alloy steel. Alloy steel, on the other hand, is a type of steel alloy that has been made to not rust. In this article, we look at the similarities and differences between carbon steel and alloy steel.